Traction sheave elevator and drive machine unit

A driving device and sheave-type technology, which is applied to elevators, transportation and packaging, elevators, etc. in buildings, can solve problems such as increasing the cross-section of elevator shafts, reduce rope wear, reduce supporting force, and save buildings effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

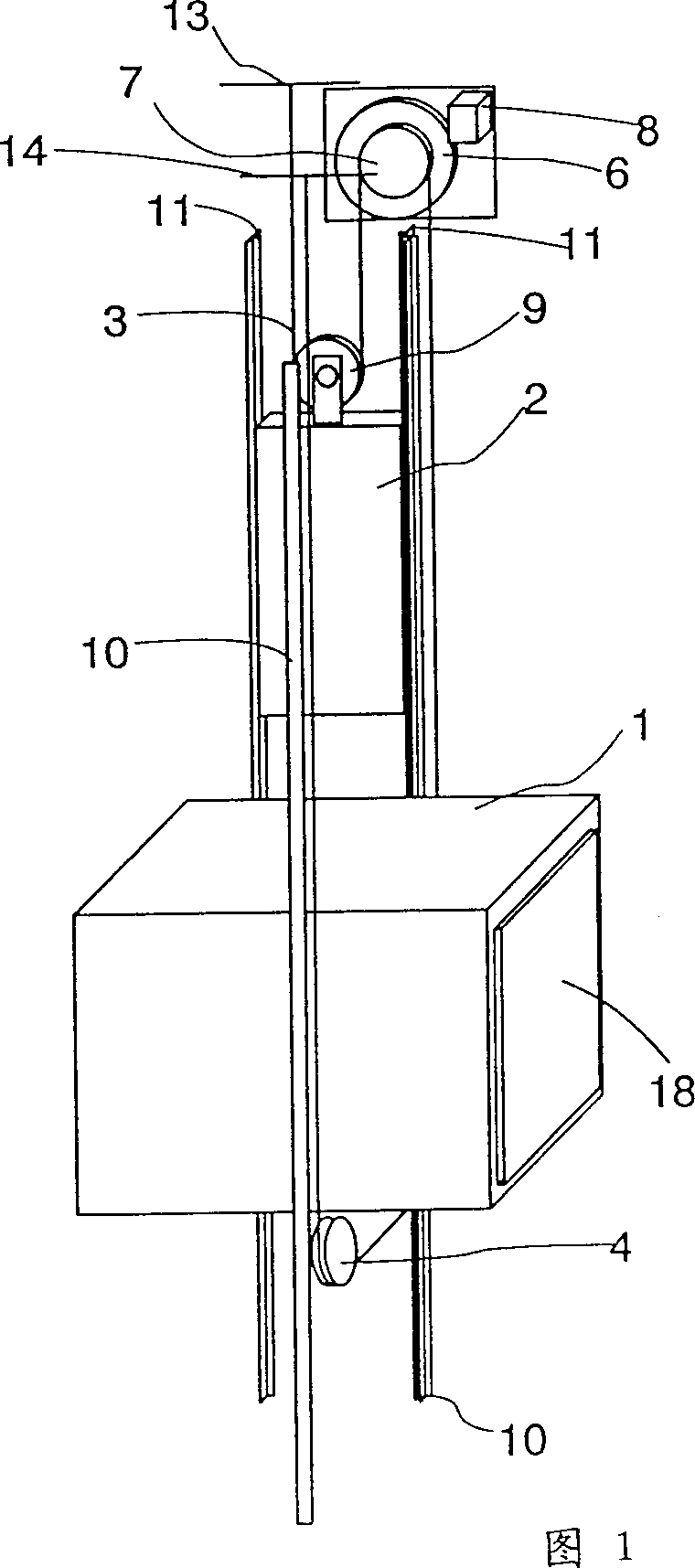

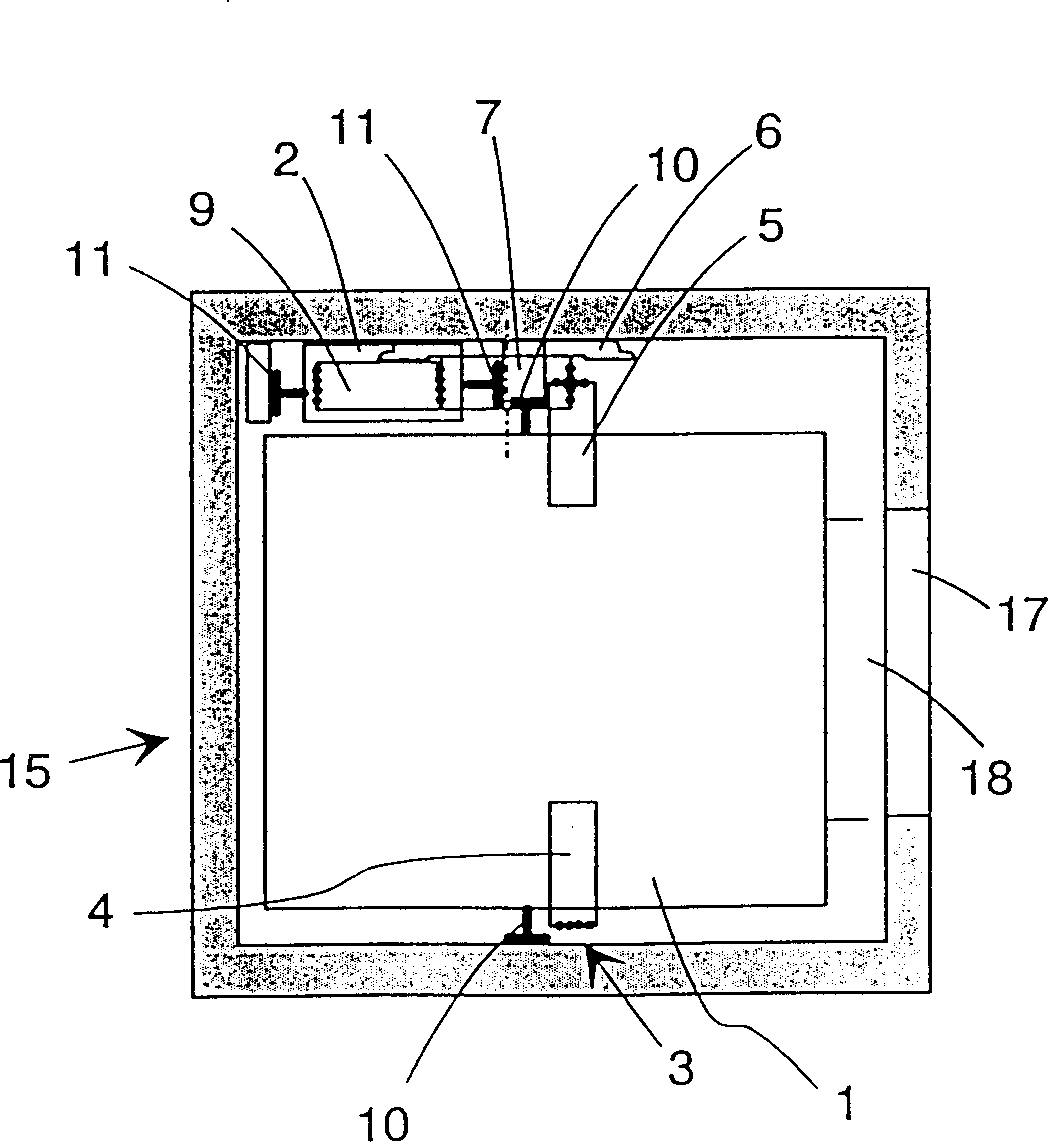

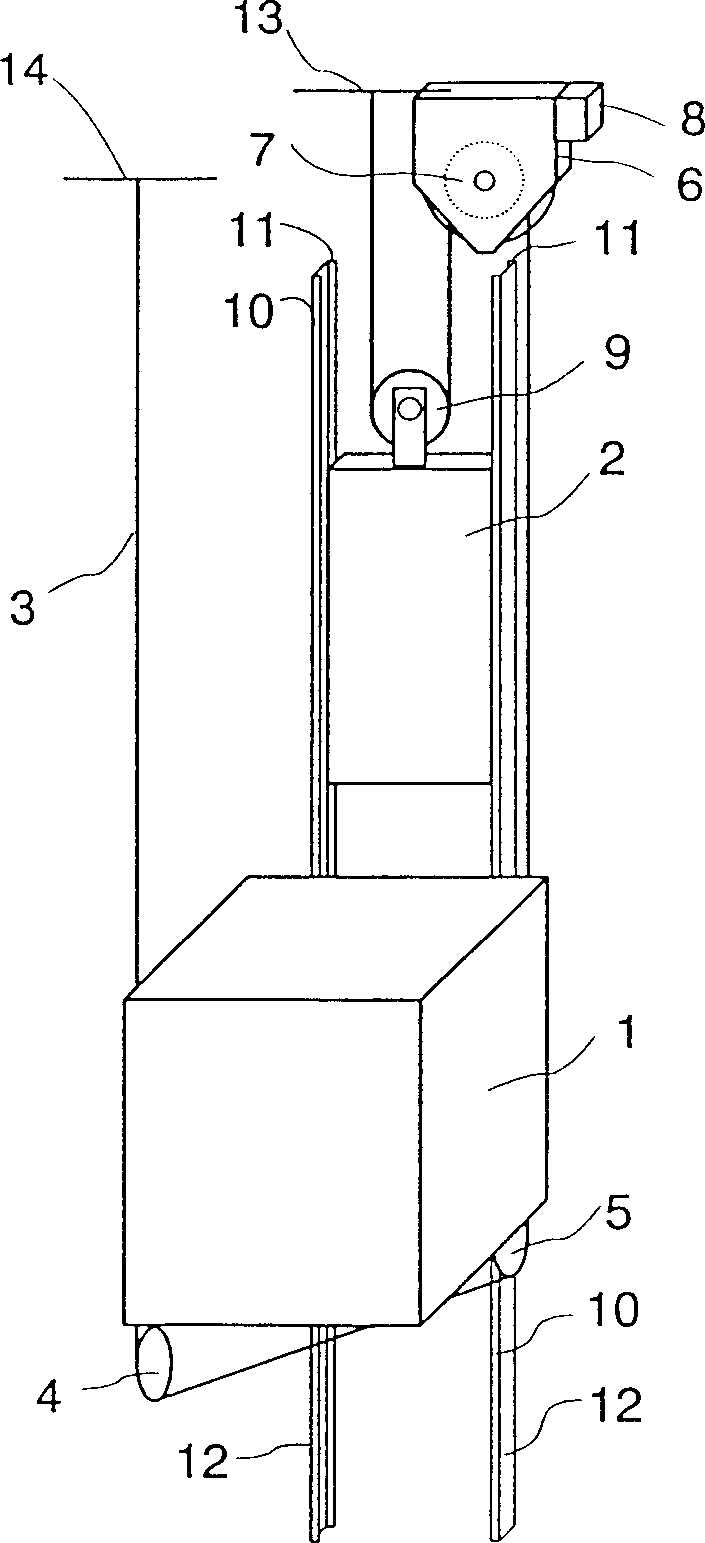

[0028] The schematic diagram of the traction sheave elevator of the present invention is shown in Fig. 1 . The car 1 and the counterweight 2 are suspended on the hoisting rope 3 of the elevator. The hoisting ropes 3 preferably support the car 1 substantially centrally or symmetrically to a vertical line passing through the center of gravity of the elevator car 1 . Likewise, the suspension of the counterweight 2 is also preferably substantially central or symmetrical about a vertical line passing through the center of gravity of the counterweight. In FIG. 1 , the car 1 is supported by the hoisting rope 3 through the diverting pulleys 4 and 5 with rope grooves, and the counterweight 2 is supported by the diverting pulley 9 with grooves. The diverting pulleys 4, 5 preferably revolve substantially in the same plane. The hoisting cable 3 usually consists of several strands arranged side by side, generally at least 3 strands. An elevator drive 6, with a traction sheave 7 engaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com