A high-voltage line maintenance device of chain-drive lifting type substation system

A high-voltage line and chain drive technology, which is applied in the field of high-voltage line maintenance devices of chain-driven elevating substation systems, can solve the problems of workers' life safety threats, potential safety hazards, and high labor intensity of operation, and achieves improved safety, guaranteed stability, The effect of avoiding electric shock events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

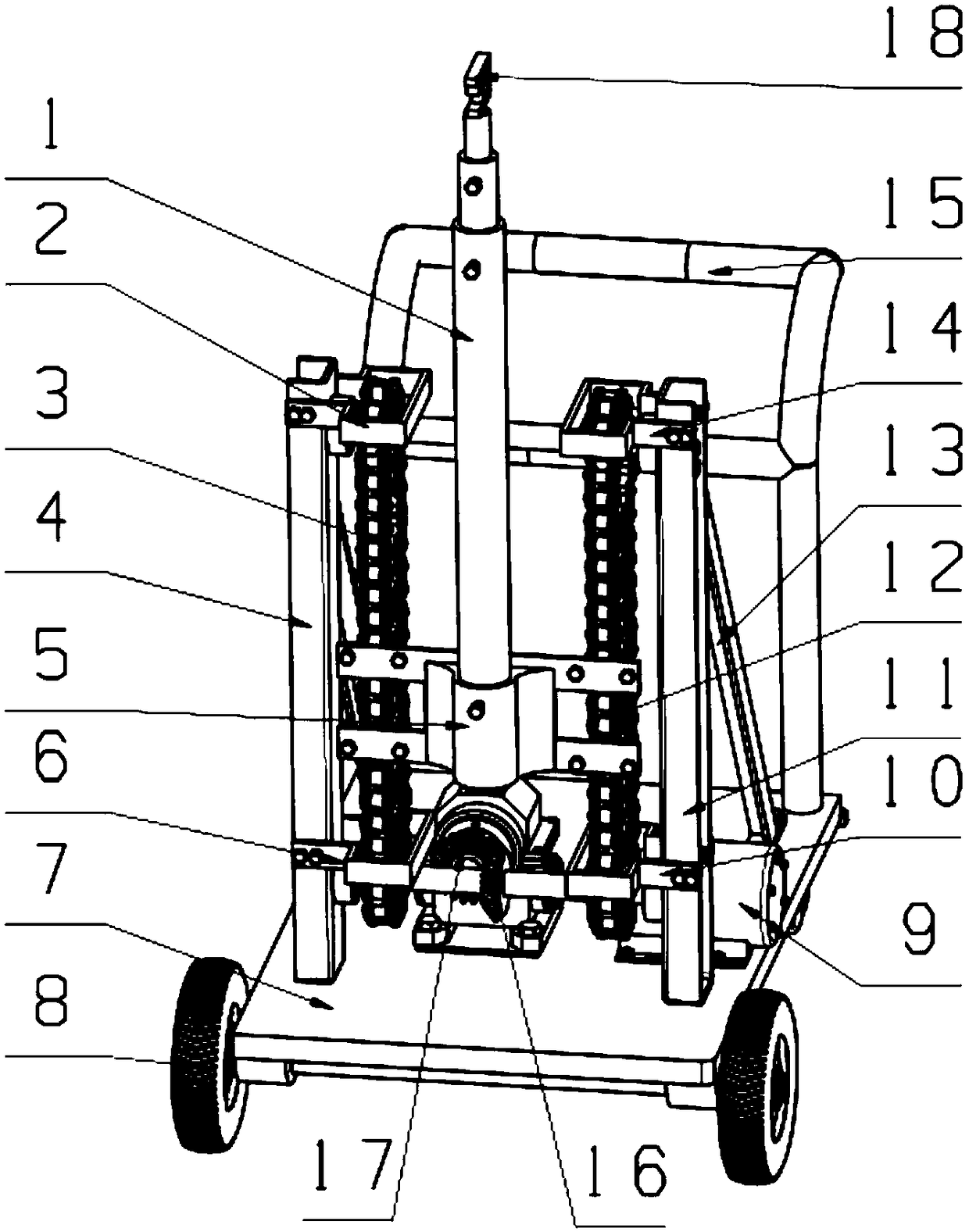

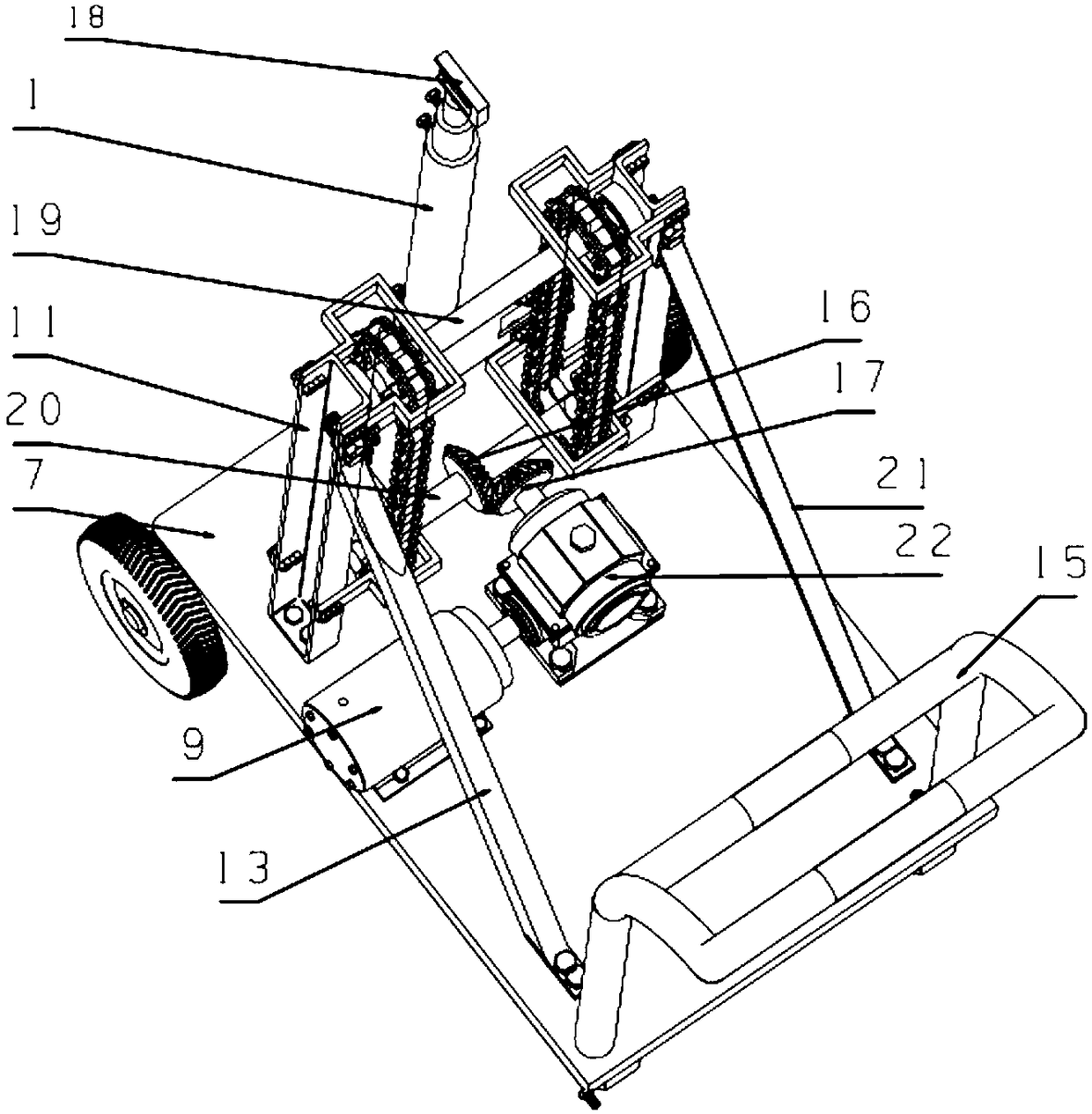

[0026] Such as Figure 1 to Figure 7 As shown, the high-voltage line maintenance device of the chain drive lifting type substation system according to the present invention includes a traveling frame, a chain lifting mechanism, a power mechanism, and a telescopic rod coupling mechanism. The specific structure and connection relationship are as follows:

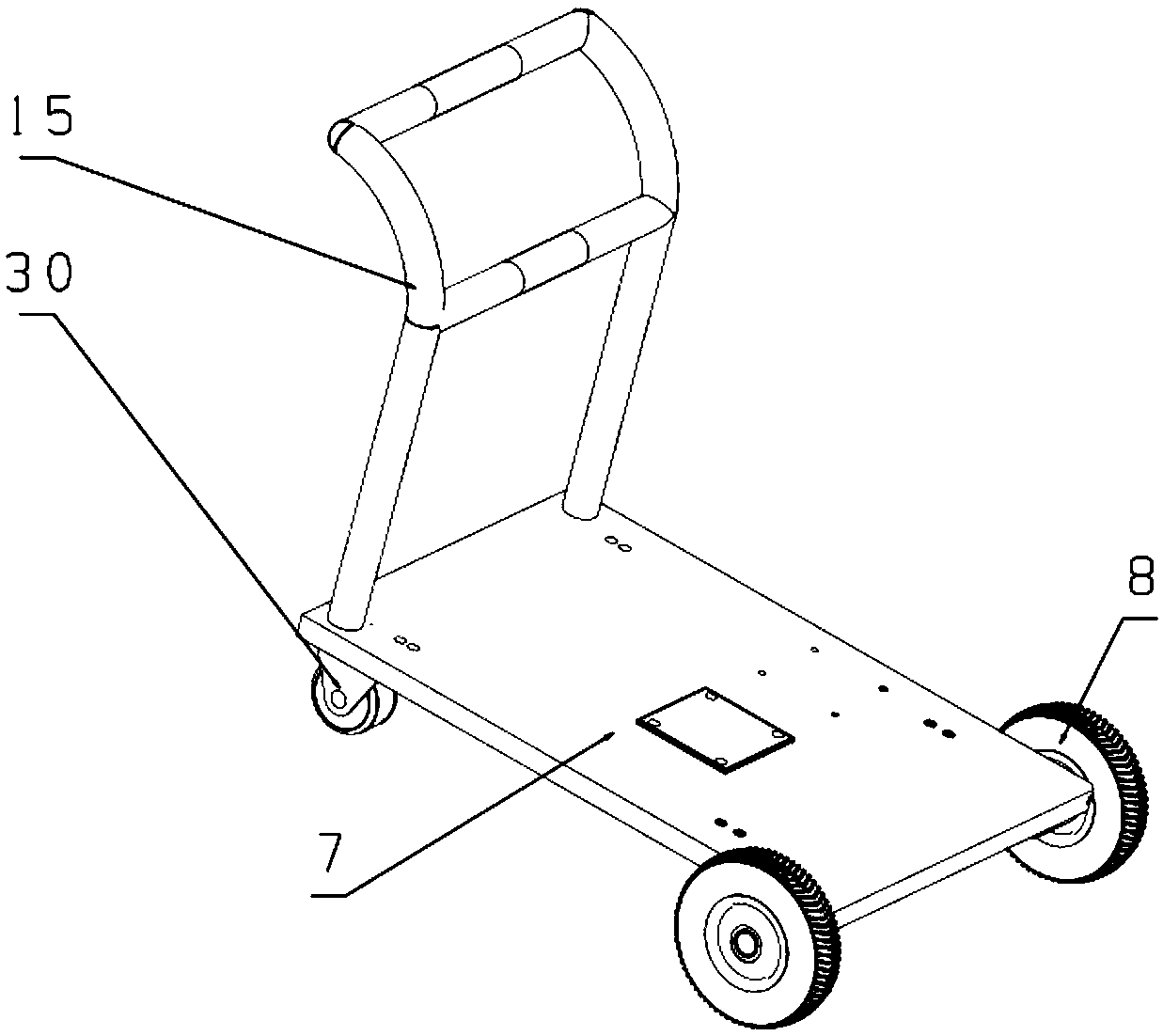

[0027] Described walking vehicle frame comprises car plate 7, front wheel 8, universal wheel 30, hand handle 15. Front wheel 8 is fixed on the front end of car plate 7 by axle, has some threaded holes for fixing chain lifting mechanism and power mechanism on car plate 7, universal wheel 30 is installed in the rear end of car plate 7, and hand handle 15 Welded to the rear end of the walking frame.

[0028] The chain lifting mechanism includes a first lifting support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com