Sounding device and method for manufacturing sounding device

A sound-generating device and vibration system technology, which is applied to the shape of the speaker diaphragm, sensors, loudspeakers, etc., can solve problems such as noise generation, achieve the effect of saving vibration space and improving the Xmax range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below through the specific implementation in combination with the attached figure 1 to attach Figure 7 The present invention will be described in further detail so as to better understand the solution of the present invention and its advantages in various aspects. In the following examples, the purpose of providing the following specific embodiments is to facilitate a clearer and more thorough understanding of the disclosure content of the present application, rather than to limit the present invention. The words indicating orientation, such as up, down, left, and right, are only for the positions of the structures shown in the corresponding drawings.

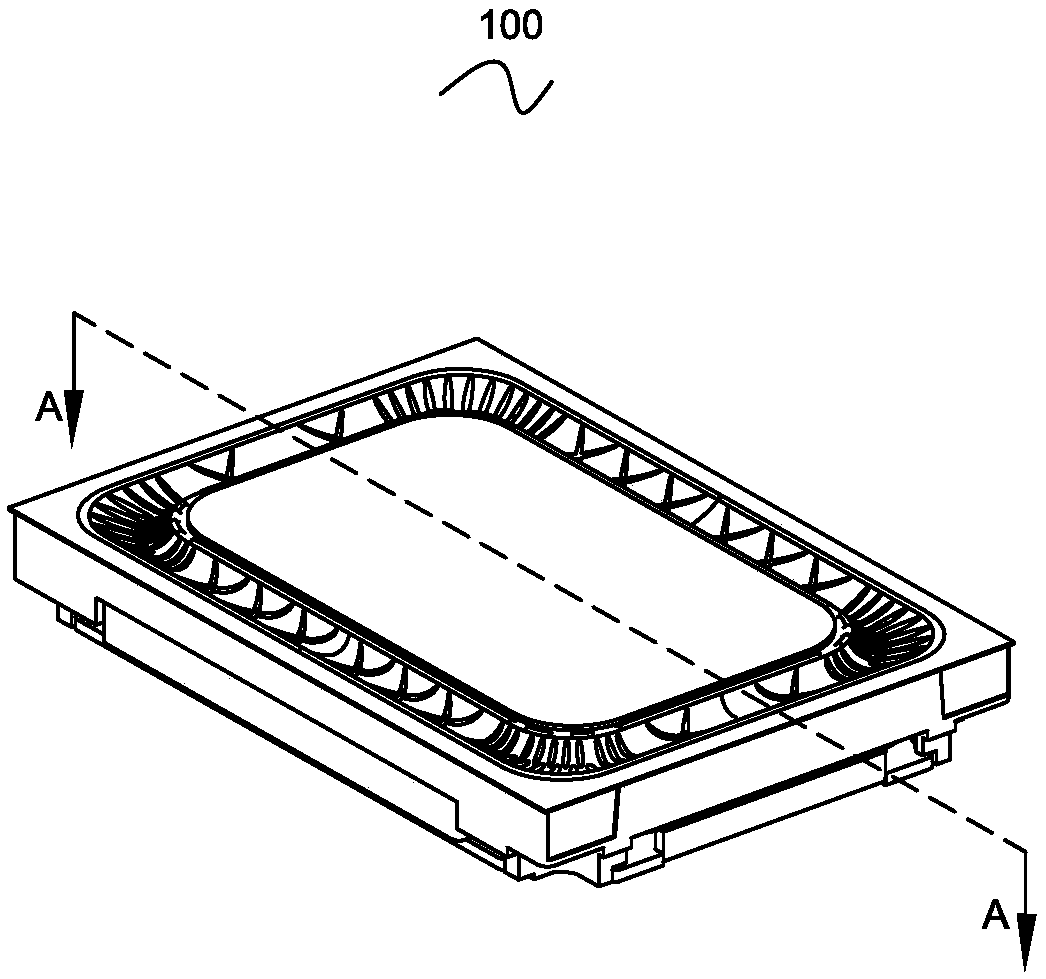

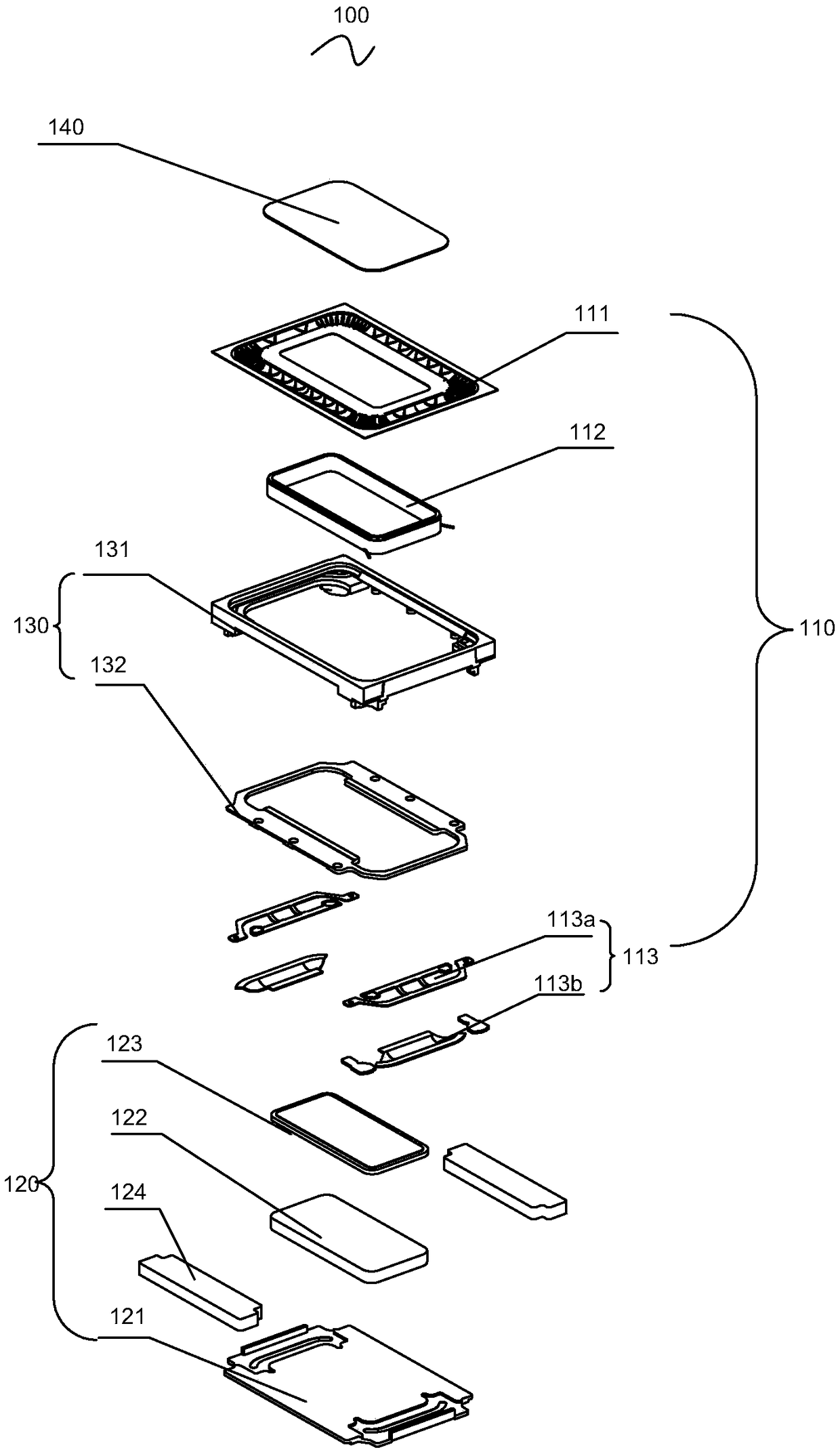

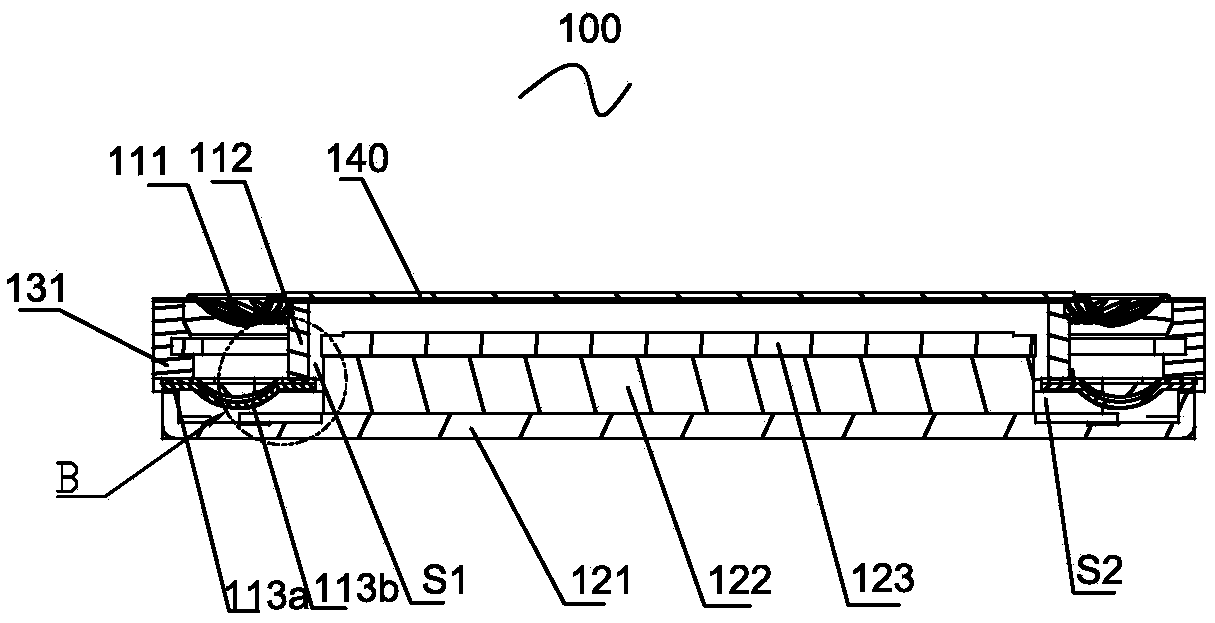

[0030] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the first aspect of the present invention relates to a sound-generating device 100, the sound-generating device 100 includes a vibration system 110, a magnetic circuit system 120, and a shell for accommodating the vibration system 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com