Water treatment device for aquaculture

A processing device and aquaculture technology, applied in the field of agricultural breeding, can solve the problems of the quality decline of aquatic products and the destruction of vegetation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

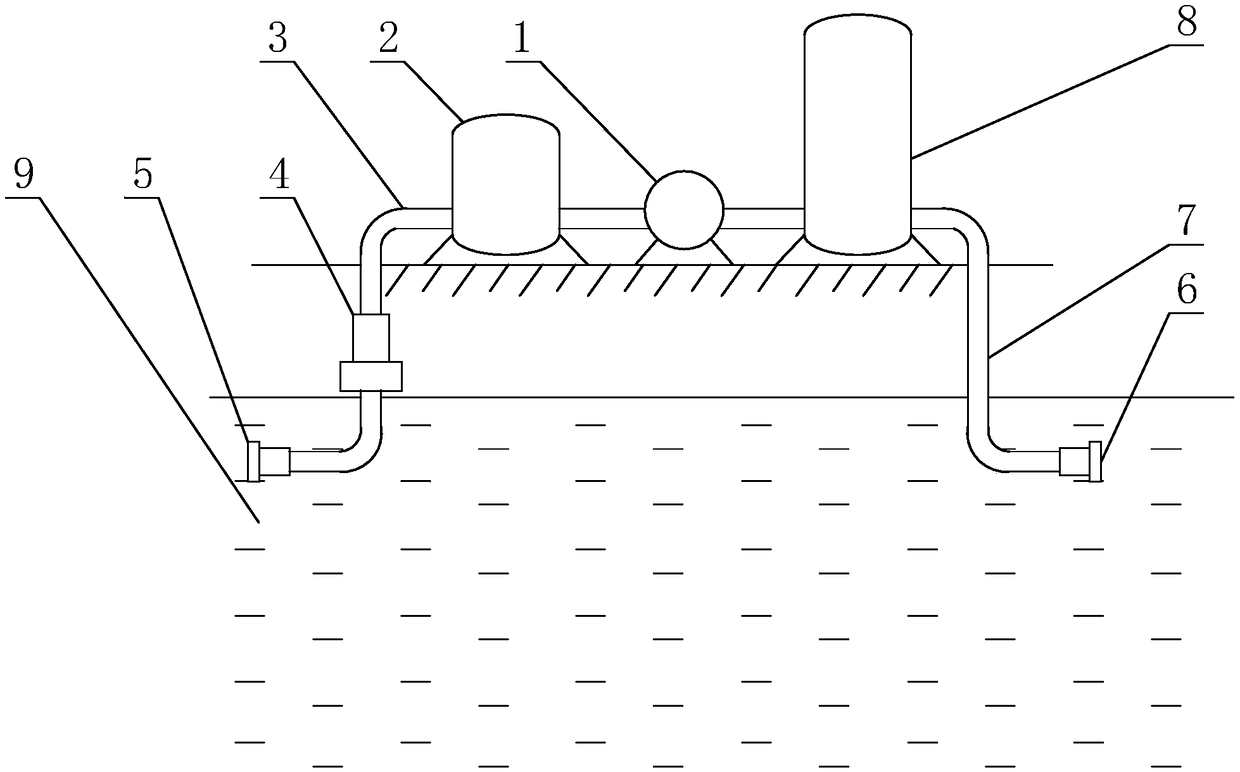

[0054] like Figure 1 to Figure 5 As shown, a kind of aquaculture water treatment device comprises the circulation system that is used to realize the circulation of water body in the culture pond 9, and described circulation system comprises pump 1, the inlet pipe 3 that is connected on the inlet end of pump 1, is connected at the outlet of pump 1 The outlet pipe 7 on the end;

[0055] The water inlet 5 of the water inlet pipe 3 faces opposite to the water outlet 6 of the water outlet pipe 7, and the water inlet 5 and the water outlet 6 are located on the same straight line;

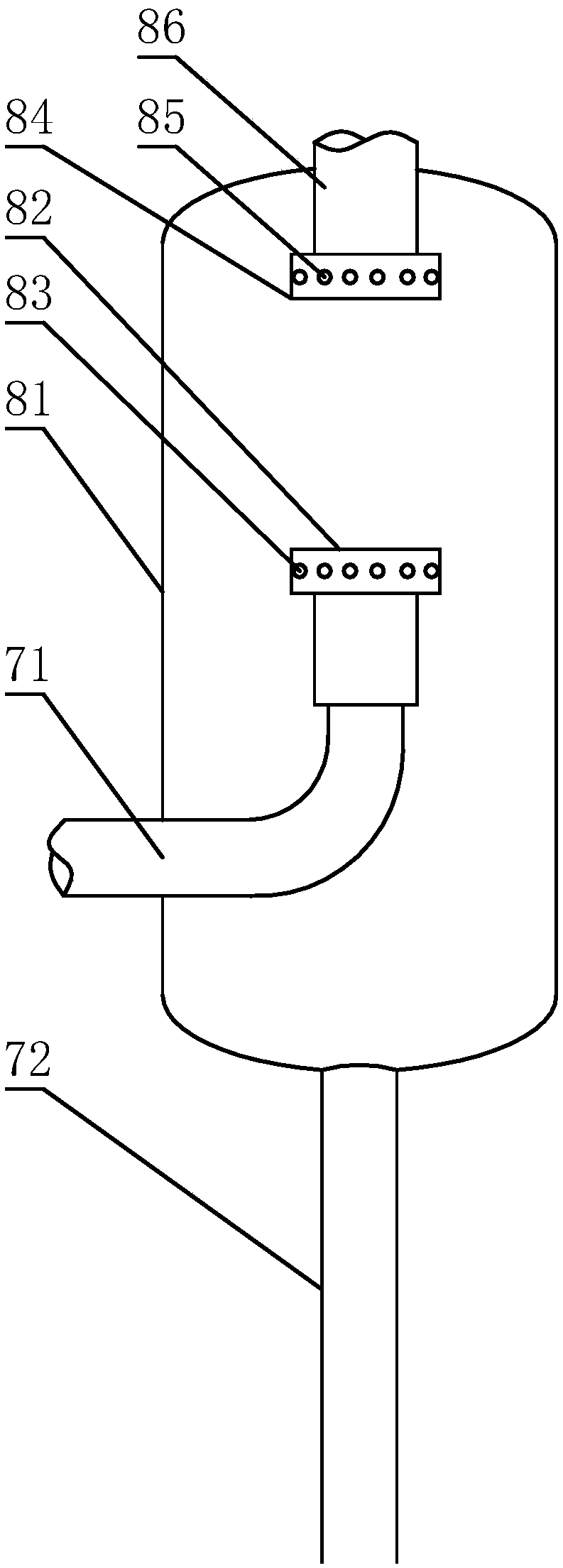

[0056] It also includes a water wheel 74 installed in the water outlet pipe 7. When the fluid flows through the water wheel 74, the fluid drives the water wheel 74 to rotate;

[0057] It also includes a conversion device 76 for converting the motion state, the input end of the conversion device 76 is connected to the water wheel 74, and a turning plate 77 connected to the output end of the conversion de...

Embodiment 2

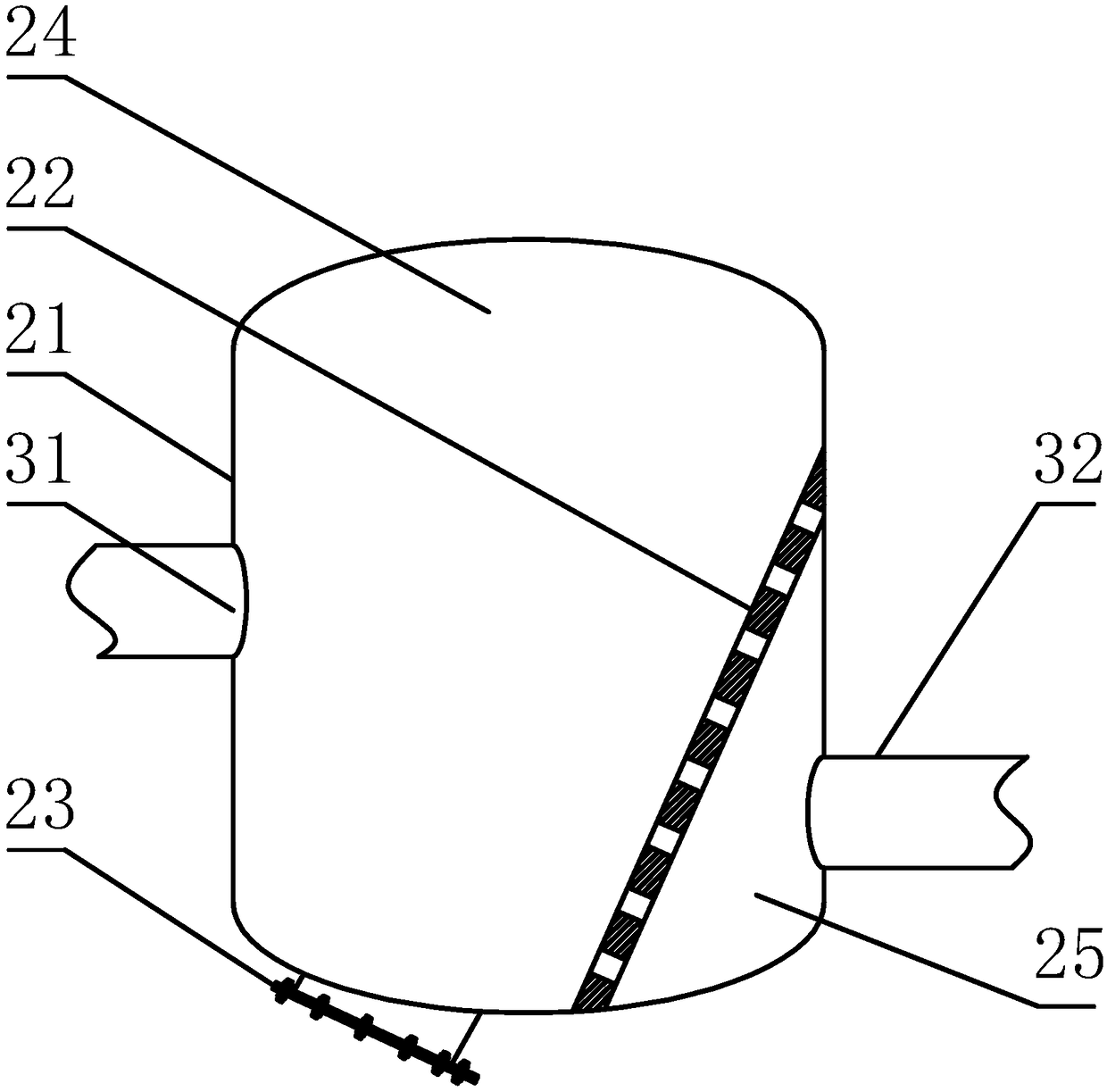

[0061] This embodiment is further limited on the technical solution provided in embodiment 1, as Figure 1 to Figure 5 As shown, as a specific realization scheme of the conversion device 76, the conversion device 76 includes a transmission shaft 761, a swing arm 763 connected to one end of the transmission shaft 761, a slider 765 connected to the swing arm 763, and a sliding block 765 arranged on it. swing bar 762 of slot 764;

[0062] The water wheel 74 is installed in the water outlet pipe 7 through the first rotating shaft 75, and when the water wheel 74 rotates, it drives the first rotating shaft 75 to rotate around the axis of the first rotating shaft 75 itself;

[0063] The first rotating shaft 75 is connected to the transmission shaft 761, and when the first rotating shaft 75 rotates, the transmission shaft 761 is driven to rotate around its own axis;

[0064] The flap 77 is connected to the water outlet pipe 7 through the second rotating shaft 771, and one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com