Hot water kettle with automatic descaling function

An automatic descaling and kettle technology, which is applied to household utensils, kitchen utensils, water-boiling utensils, etc., can solve problems such as affecting the heating efficiency of the electric heating tube and increasing the power consumption of the electric heating tube, so as to improve the use range, The effect of ensuring power consumption and ensuring the descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

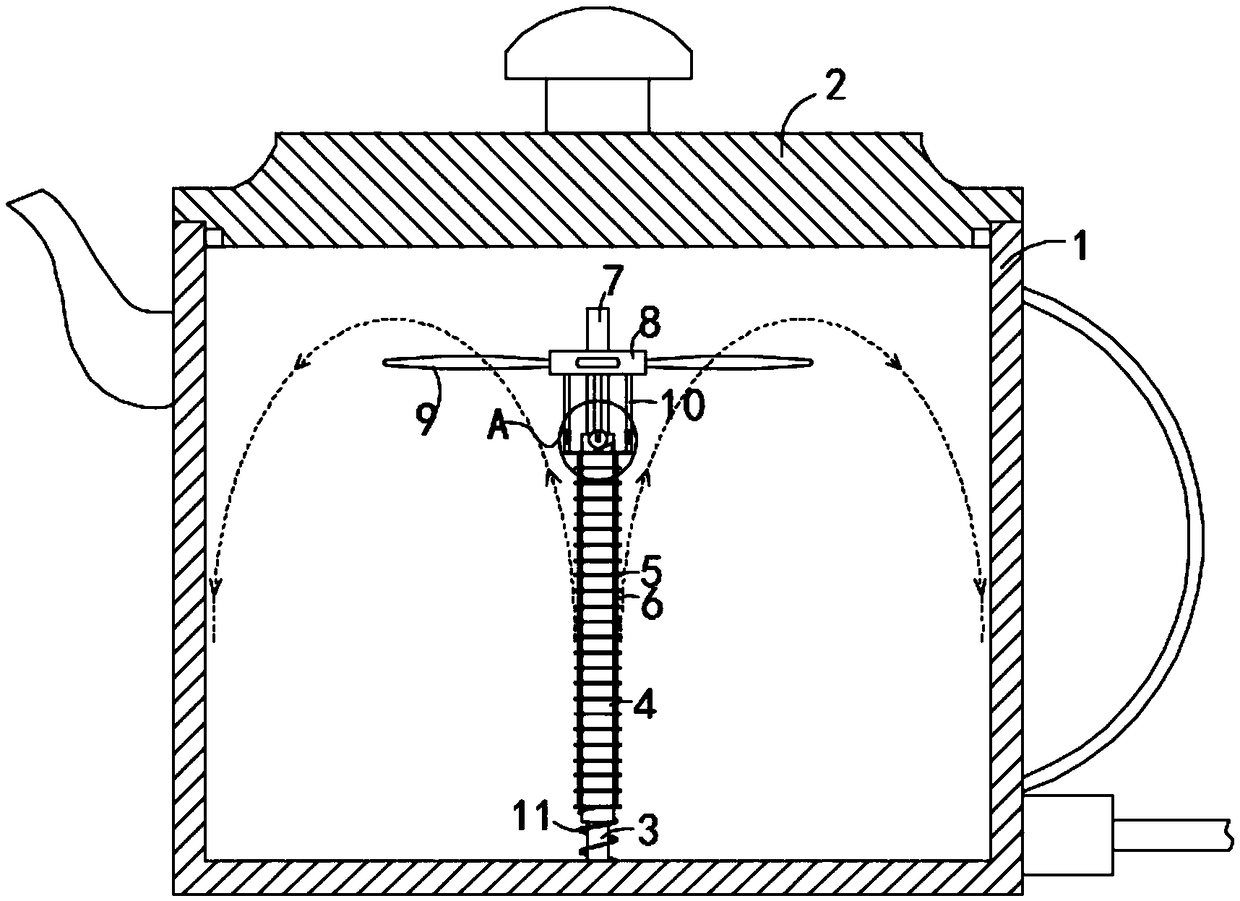

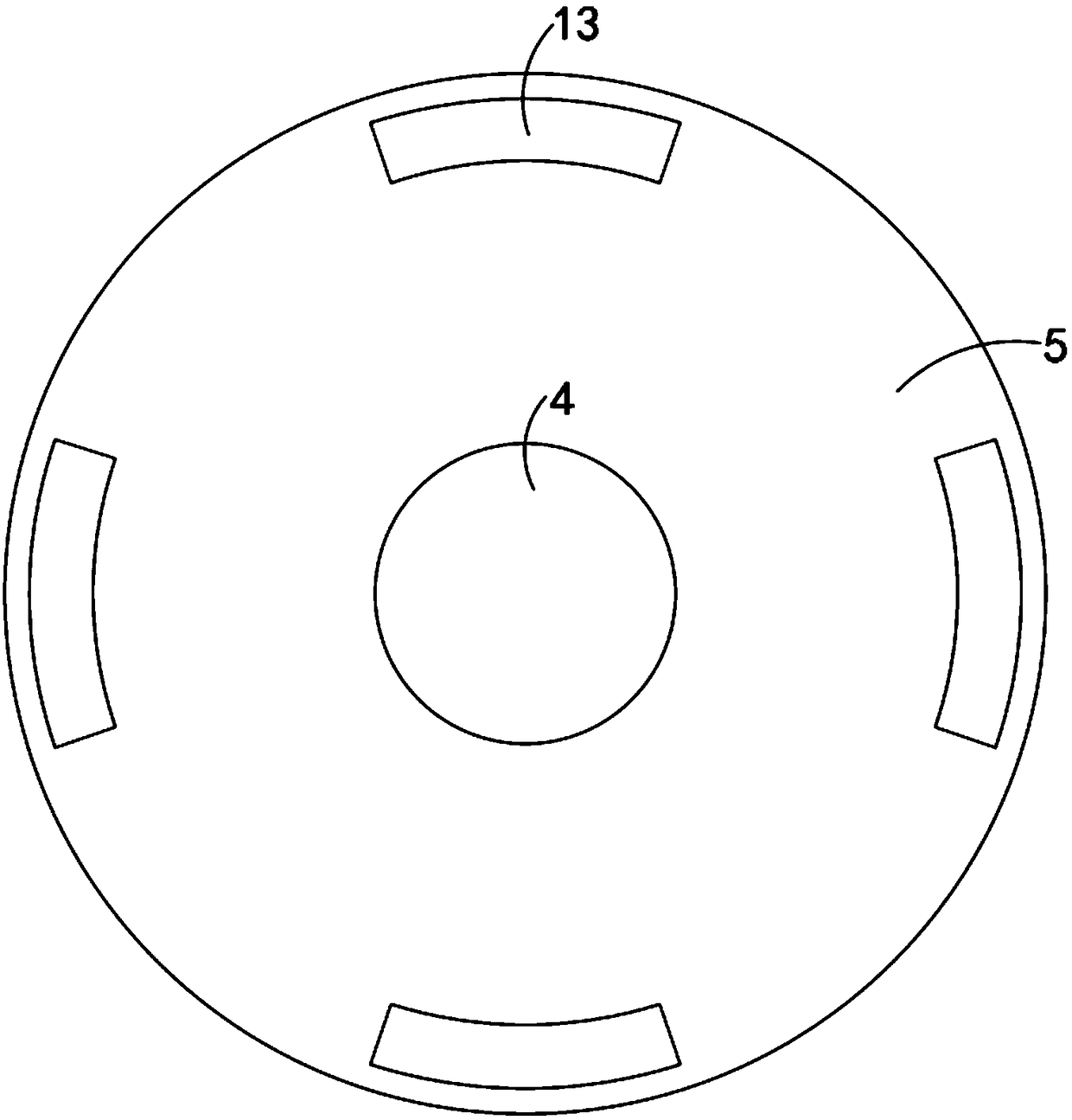

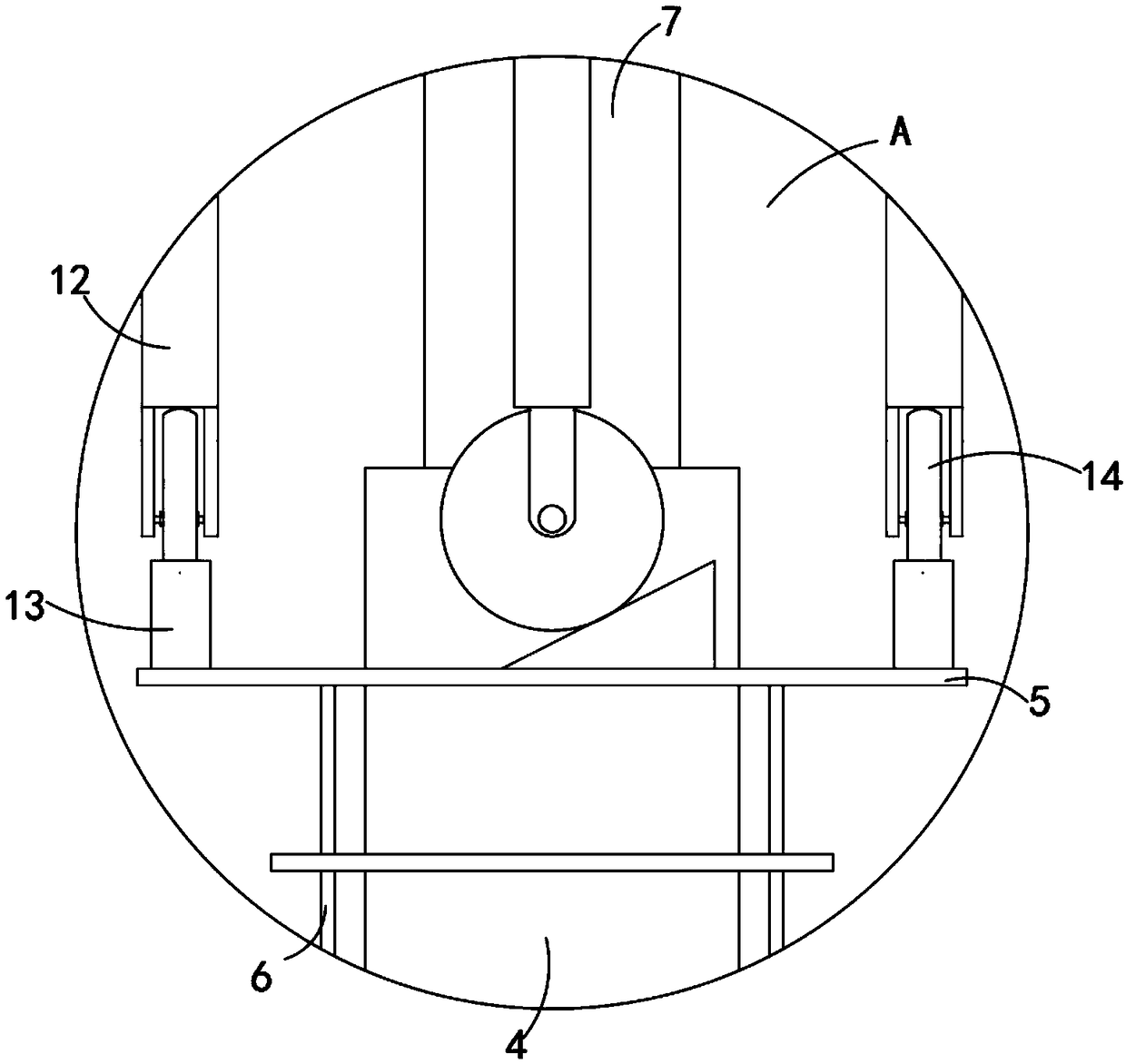

[0021] like Figure 1-4 As shown, a kettle with an automatic descaling function includes a kettle body 1, and a matching kettle lid 2 is provided at the mouth of the kettle body 1, and the bottom of the kettle body 1 is fixedly connected to a support rod 3 to support The upper end of the rod 3 is vertically equipped with an electric heating tube 4, wherein the specific mechanism and working principle of the electric heating tube 4 are all prior art, and will not be repeated here. The electric heating tube 4 is not vertically cylindrical, which is convenient for its The scale on the surface is removed, and the coaxial sleeve on the electric heating tube 4 is provided with a plurality of scraper rings 5 for descaling. A plurality of vertical rods 6 are vertically installed between two adjacent scraper rings 5, and the electric heating tube The upper end face of 4 is vertically equipped with a fixed rod 7, and the fixed rod 7 is fixedly sleeved with a collar 8. On the annular s...

Embodiment 2

[0025] like Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that: the bottom of the kettle body 1 is fixedly connected with a foam collecting tube 15, and the foam collecting tube 15 is covered on the outside of the scraper ring 5 and does not contact it, and the lower end of the foam collecting tube 15 The part is hollowed out, and the uppermost scraper ring 5 is located above the bubble collection tube 15, and the diameter of the uppermost scraper ring 5 is larger than the nozzle diameter of the bubble collection tube 15. It should be noted that the bubble collection tube 15 has good thermal conductivity. metal pipe, and the influence on the heating of the electric heating pipe 4 is negligible.

[0026] In this embodiment, the bubbles generated on the surface of the electric heating tube 4 are discharged through the gap between the bubble collecting tube 15 and the uppermost scraping ring 5, Figure 5 The direction of the arrow in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com