A tube shell horizontal liquid film flipping falling film absorption device using ω-shaped spring

A falling film absorption, tube shell horizontal technology, applied in the direction of absorbent/adsorbent, refrigeration and liquefaction, climate change adaptation, etc., can solve the problem of uneven distribution of liquid film, decrease of absorption rate, and reduction of effective absorption area of liquid film and other problems, to achieve the effect of uniform liquid film distribution, enhanced liquid film disturbance, and enhanced heat and mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

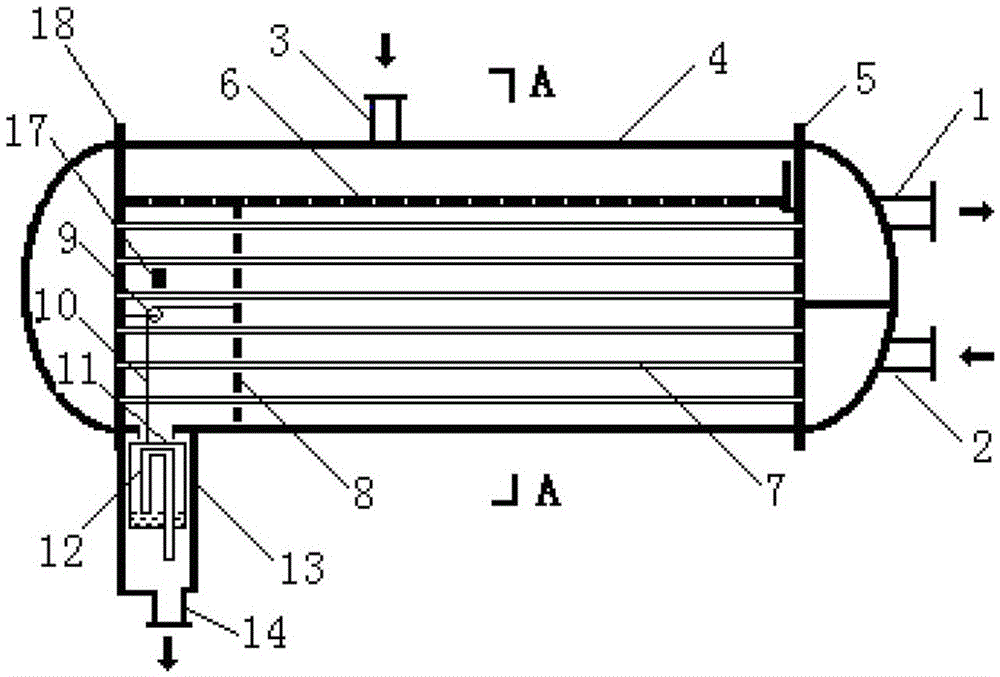

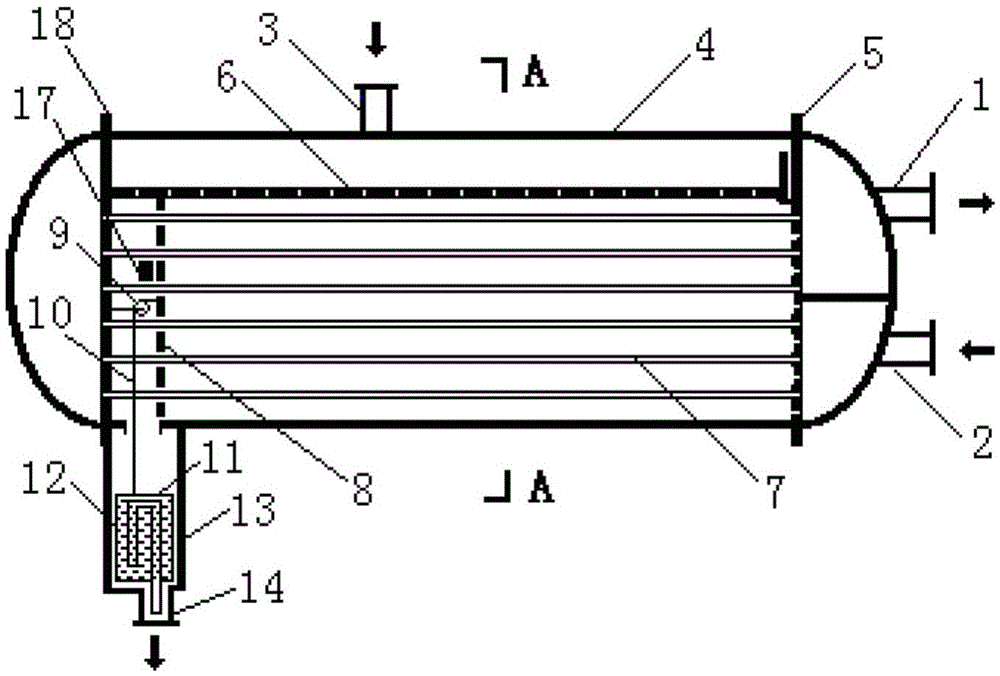

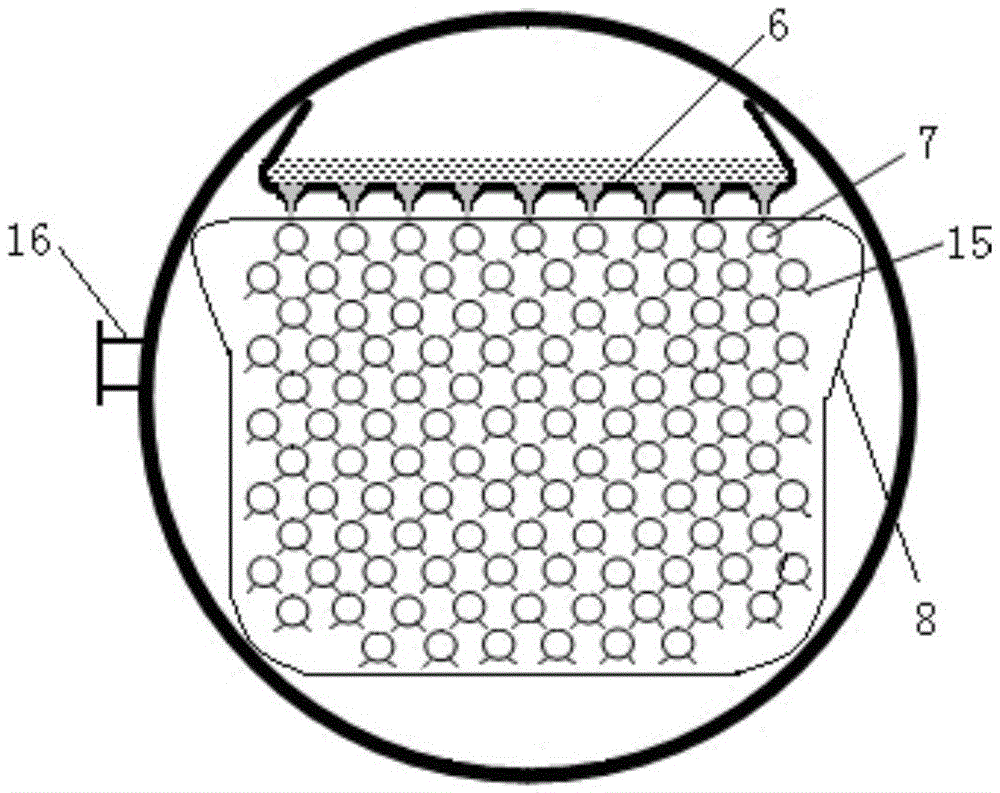

[0030] like Figure 1 to Figure 5 As shown, the tube shell horizontal liquid film flipping falling film absorbing device adopting an Ω-shaped spring of the present invention includes a housing 4, a first partition 5, a liquid distribution plate 6, a horizontal falling film tube 7, a movable Orifice plate 8, fixed pulley 9, pulley line 10, suspended liquid contact barrel 11, siphon pipe 12, liquid outlet pipe 13, gas inlet 16 and second partition 18. The first partition 5 and the second partition 18 are respectively fixedly connected to two ends of the inner chamber of the casing 4 . One end of the housing 4 is provided with a cooling medium outlet 1 and a cooling medium inlet 2 , the middle wall of the housing 4 is provided with a gas inlet 16 , and the top of the housing 4 is provided with a solution inlet 3 . The liquid outlet pipe 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com