Microscopic needle holder

A needle-holding pliers and pliers head technology, which is applied in the field of microsurgical wound suture in laryngology, can solve the problems of easy desoldering of welding points, short service life, unstable and unstable clamping needles, etc., and achieve a firm drive connection point , Reduce the difficulty of operation and save the cost of procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

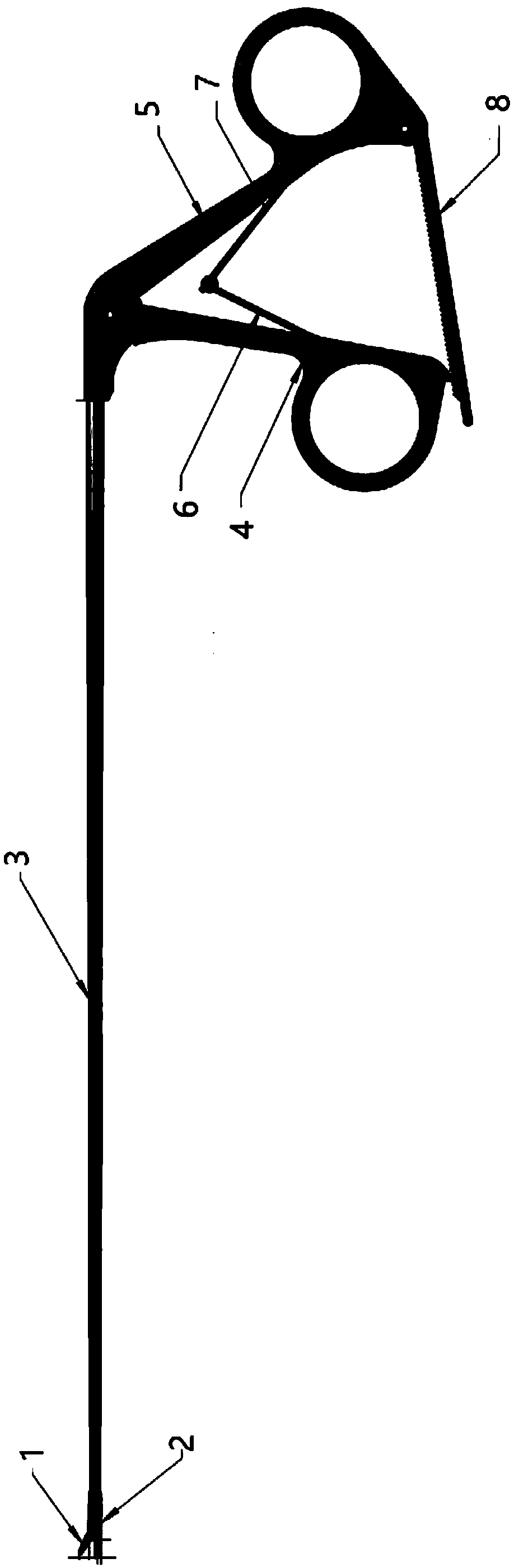

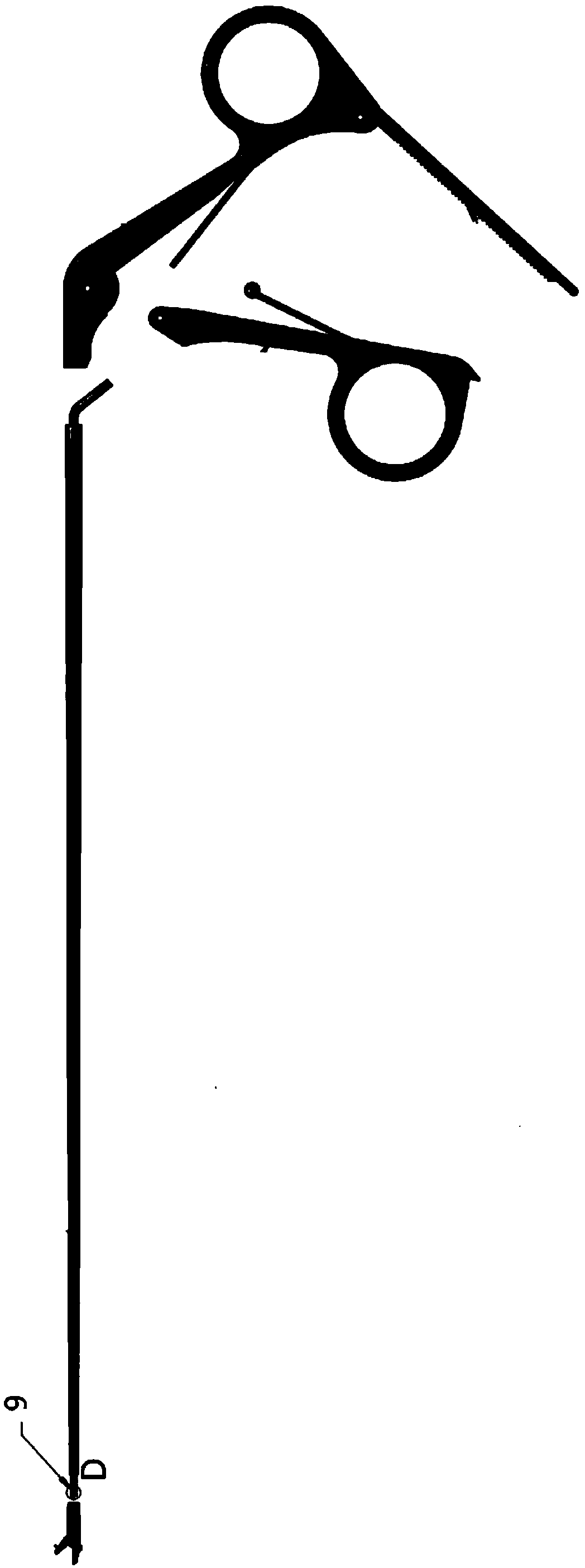

[0021] Embodiment: As shown in the accompanying drawings, this microscopic needle-holding forceps mainly includes an upper forceps head 1, a lower forceps head 2, a throat needle-holding forceps pipe 3, a front handle 4, a rear handle 5, a front spring leaf 6, a rear Spring leaf 7, lock buckle 8, drive rod 9, hole A91, cross pattern 12, horizontal pattern 21, upper clamp head 1 connects lower clamp head 2 and drive rod 9 and is installed on the front end of throat needle holder tube 3, drive rod 9 pass through the throat needle holder pipe 3 and be connected to the front handle 4, the front handle 4 is connected to the rear handle 5 installed at the rear end of the throat needle holder pipe 3, the front spring leaf 6 and the rear spring are connected between the rear handle 5 and the front handle 4 The spring leaf 7 is separated from each other, the rear handle 5 and the bottom of the front handle 4 are connected with the lock 8 to realize locking, the inner surface of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com