A high-efficiency circulating rubber pulverizer

A cyclic, pulverizer technology, applied in solid separation, chemical instruments and methods, metal processing, etc., can solve the problems of incomplete rubber pulverization, dead corners at the bottom of the machine body, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

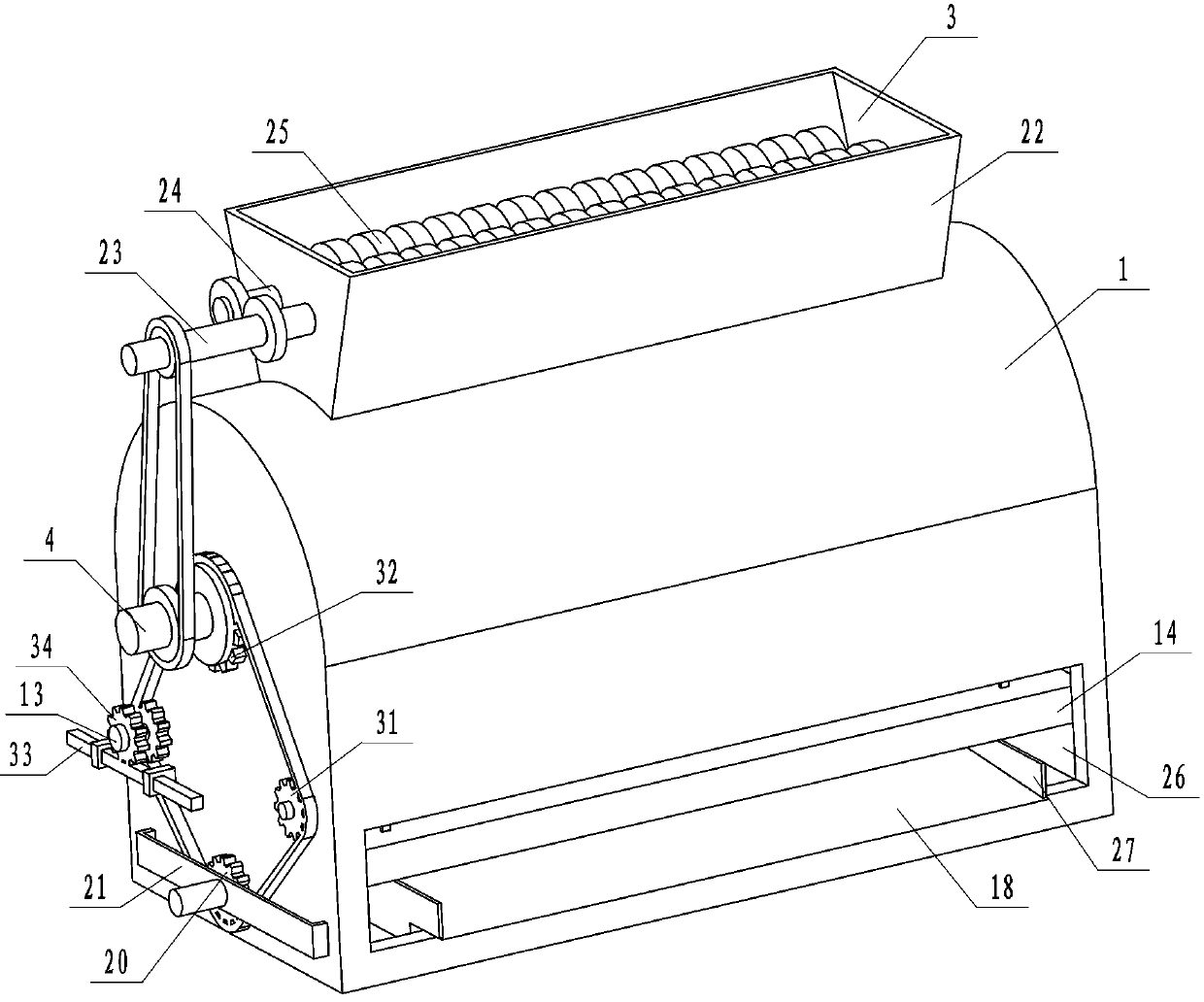

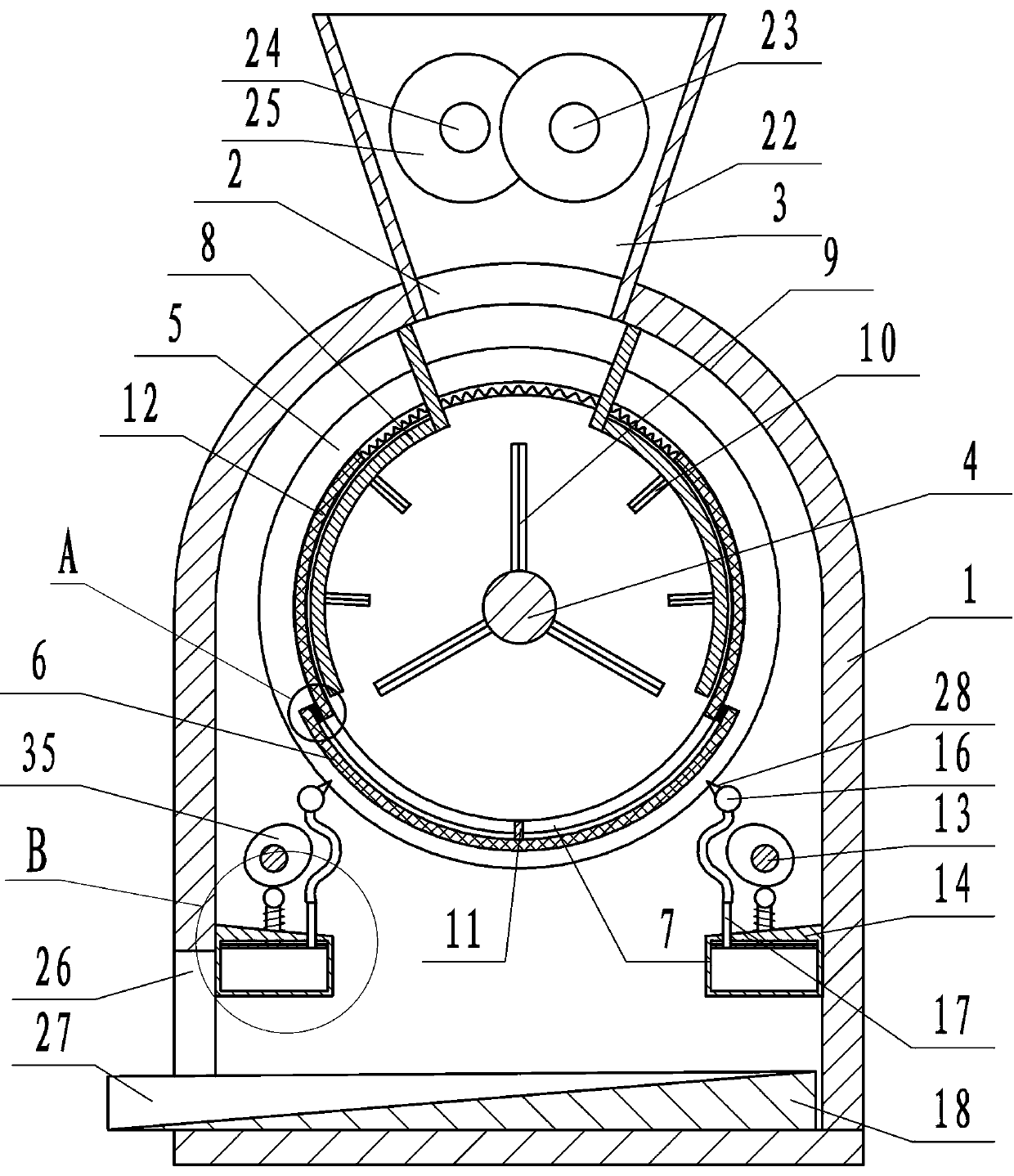

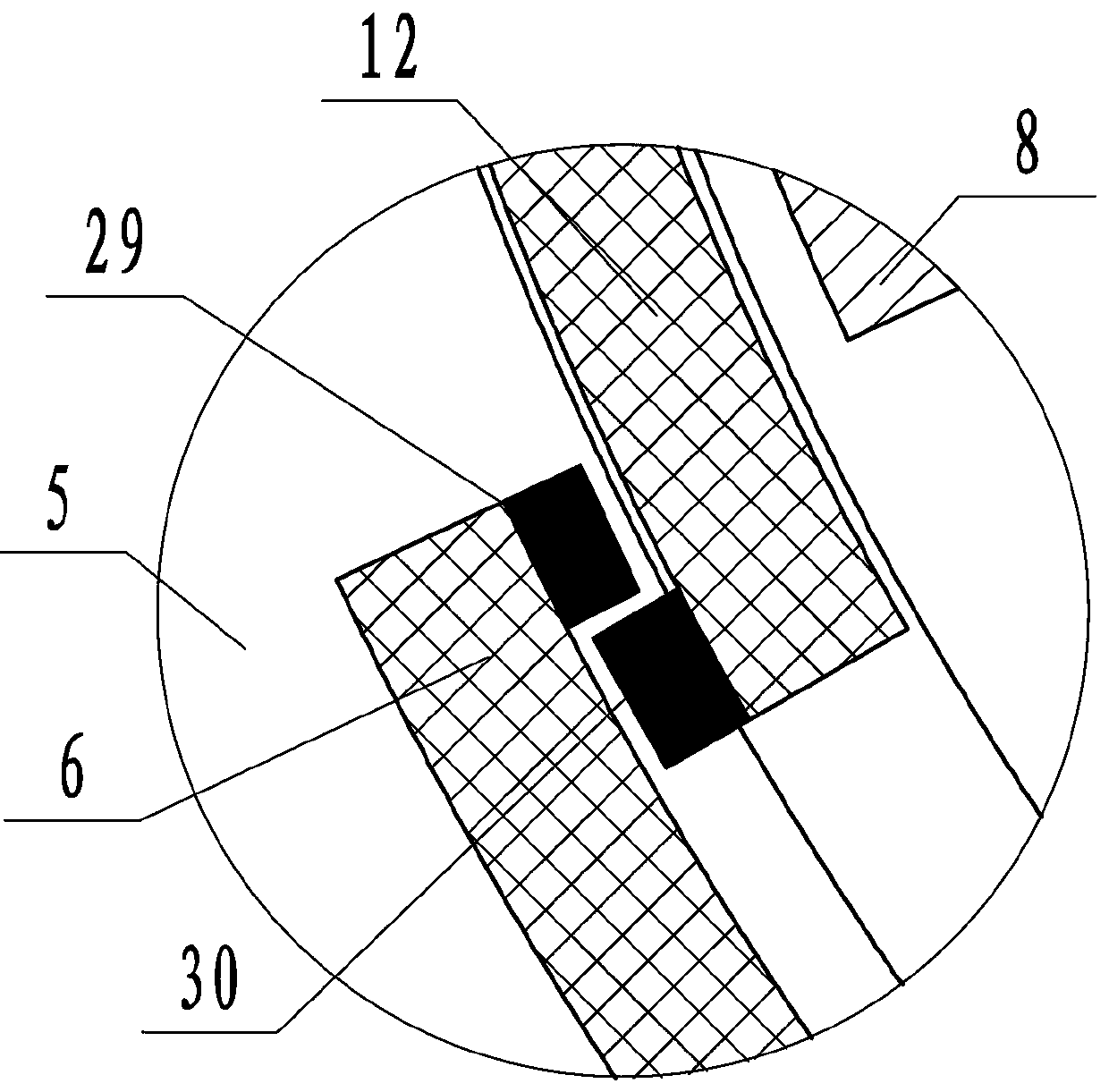

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Depend on Figure 1 to Figure 7 Provide, the present invention comprises the body 1 of horizontal arrangement, is provided with feed inlet 2 above body 1, and tearing type crusher 3 is housed on body 1, and the discharge place of crusher 3 and the feed inlet 2 of body 1 Correspondingly; the first rotating shaft 4 placed in the front and rear direction runs through the body 1, and the front and rear ends of the first rotating shaft 4 are equipped with a disc 5 that can rotate relative to the first rotating shaft 4. Between the front and rear two discs 5 The first filter screen 6 of arc is fixedly installed; The vertical baffle plate 11 that front and rear directions are placed is equipped with on the first filter screen 6 inner wall; Two arc-shaped second filter screens 12 symmetrically distributed in the two annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com