Traditional Chinese medicine active ingredient extraction equipment

A technology of active ingredients and extraction equipment, which is applied in the field of extraction equipment for active ingredients of traditional Chinese medicine, can solve problems such as inability to carry out batch extraction, low extraction rate of active ingredients of medicinal materials, time-consuming and labor-intensive problems, etc., to increase the extraction range, improve the extraction effect, and improve the extraction efficiency. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

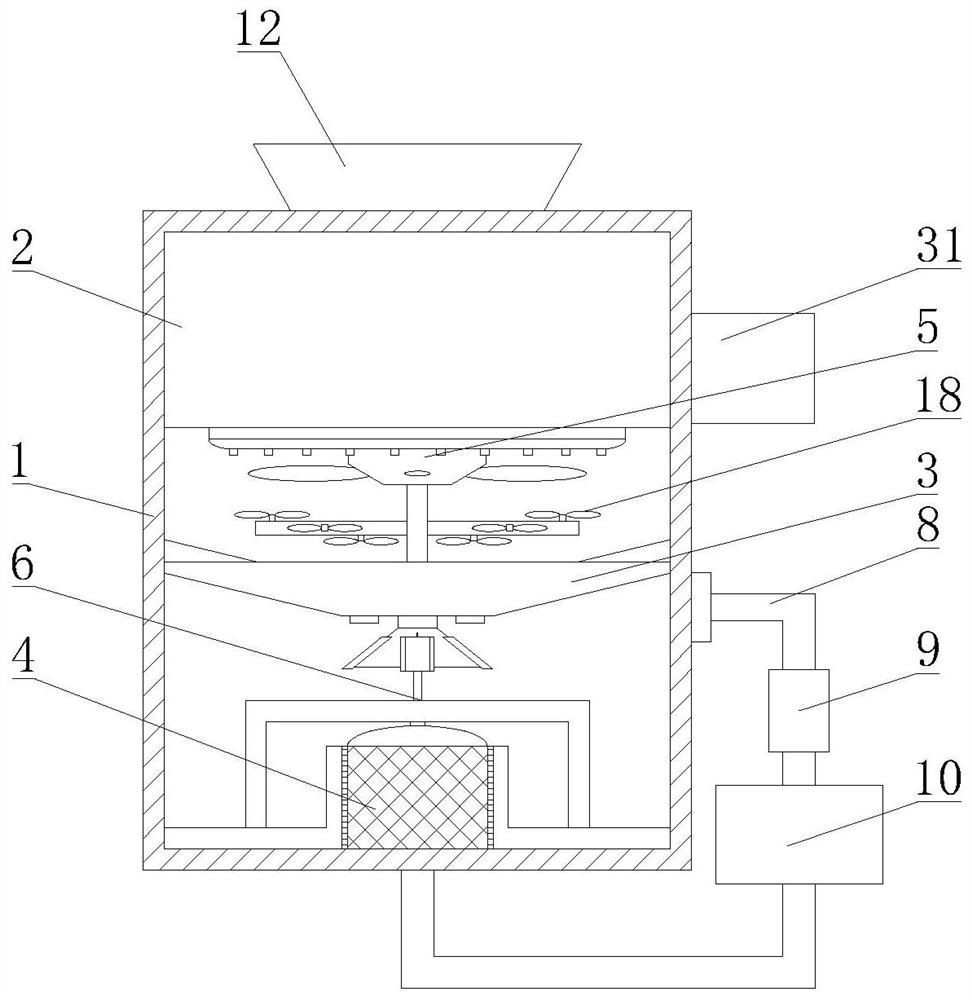

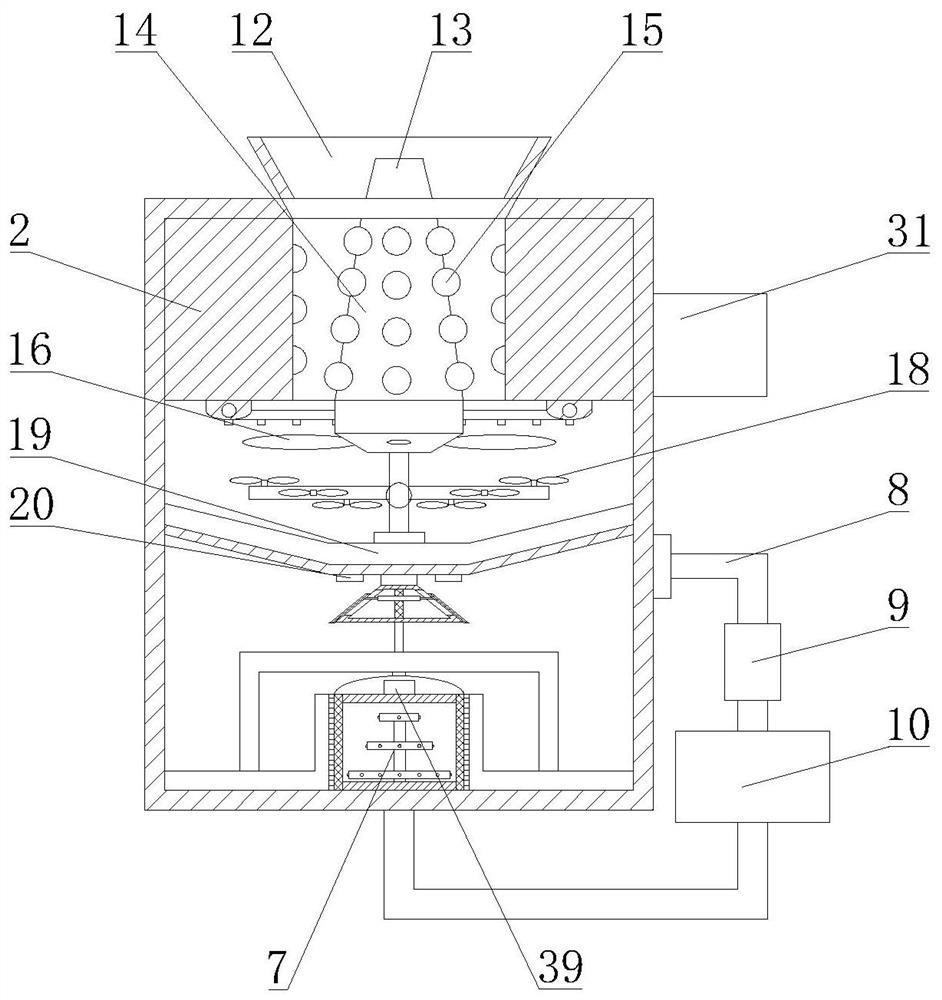

[0039] like Figure 1-5 As shown, a kind of active ingredient extraction equipment of traditional Chinese medicine proposed by the present invention includes a tank body 1, a material guide cylinder 2, a material guide cover 3, a filter cylinder 4, a crushing assembly 5, a material guide mixing assembly 6, a steam outlet 7, a connecting Pipe 8, condenser 9, steam generator 10 and controller 11; material guide cylinder 2, material guide cover 3, and filter cylinder 4 are arranged in the tank body 1 from top to bottom; a feed hopper 12 is arranged at the upper end of the tank body 1 , communicated with the upper end of the material guide cylinder 2; the crushing assembly 5 is arranged on the tank body 1, and extends into the material guide cylinder 2, and extends to the material guide cover 3; the material guide mixing assembly 6 is arranged outside the filter cylinder 4; the steam outlet 7 is arranged in the filter cartridge 4; the lower end of the communication pipe 8 communic...

Embodiment 2

[0047] like Image 6 As shown, on the basis of the foregoing embodiments, the position of the material guide 21 corresponding to the discharge pipe 20 is set in the present invention, including a material guide platform 26, a threaded rod, a telescopic frame 27 and a material guide hopper 28; the material guide platform 26 is arranged on the guide At the bottom of the material cover 3, an installation chamber is arranged inside, and a guide groove 29 is arranged on the side wall; the guide hopper 28 slides along the guide groove 29; the threaded rod is transmitted through the rotating shaft 25, and the rotation is arranged in the installation chamber; the telescopic frame 27 is threaded with the threaded rod, Move up and down in the installation room, the telescopic end passes through the guide groove 29 on the corresponding side, connects to the guide hopper 28, and the telescopic end is reset by a spring.

[0048] In the present invention, the material guide 21 is provided, ...

Embodiment 3

[0050] like Figure 7 As shown, on the basis of the above-mentioned embodiments, the steam outlet part 7 in the present invention includes a steam outlet pan 33 and a steam outlet pipe 32; the steam outlet pipe 32 communicates with the communication pipe 8; The steam pan 33 is arranged coaxially on the steam outlet pipe 32 successively from bottom to top, and its diameter gradually decreases, and the side wall is provided with a steam outlet.

[0051] In the present invention, multiple groups of steam outlet trays 33 are arranged to cooperate to generate position difference, staggered steam outlet, increase the extraction range of steam, and improve the extraction rate of steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com