A method for flotation recovery of tantalum and niobium from alkaline feldspar granite tantalum and niobium ore

An alkaline feldspar and granite technology, applied in flotation, solid separation, etc., can solve the problems of unfavorable tantalum and niobium recovery and concentrate grade, large dosage of chemicals, and high beneficiation cost, so as to improve flotation grade and recovery rate, The effect of reducing production cost and improving flotation grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

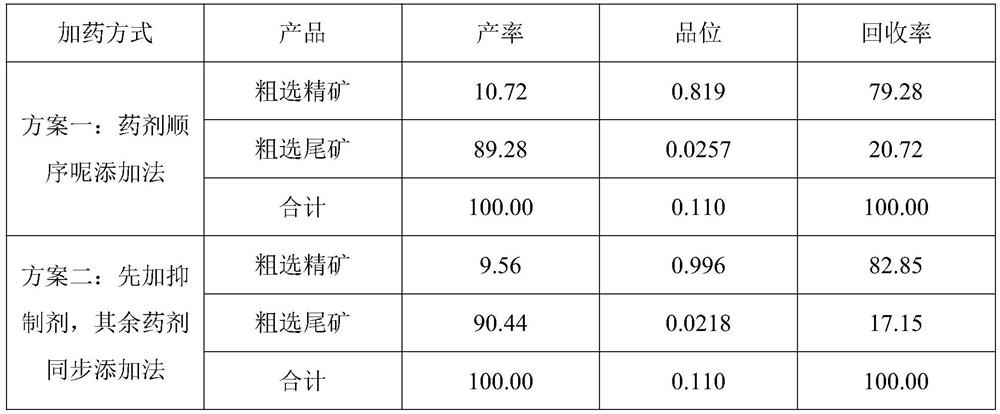

[0026] An alkaline feldspar-granite tantalum-niobium deposit in Jiangxi, in which (TaNb) 2 o 5 The content of tantalum and niobium in the ore is 0.11%; the main tantalum-niobium minerals in the ore are manganese-niobite, rich-dilute gold ore, niobium-iron rutile, etc.; the gangue minerals are mainly quartz, feldspar, sodium amphibole, etc.; It is finer, with the main particle size ranging from 0.01 to 0.16mm, which is not suitable for gravity recovery, so tantalum and niobium are recovered by flotation.

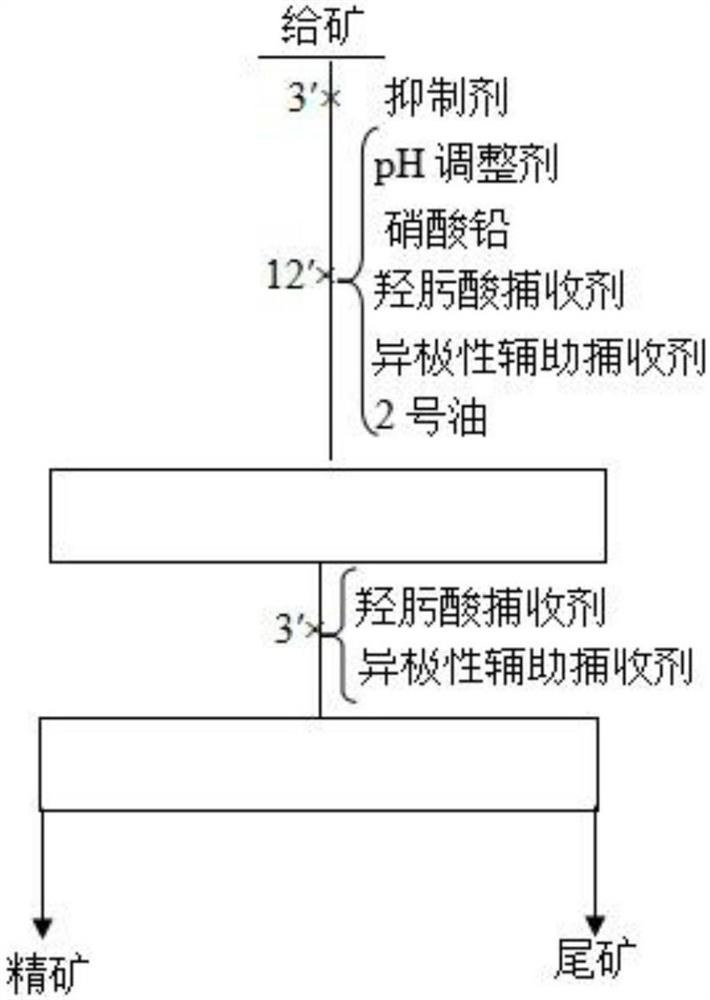

[0027] Option 1: Sequential addition of agents: Grind ore to -0.074mm to account for 80-85%, then add sodium carbonate, acidified water glass 400g / t, lead nitrate 400g / t, benzohydroxamic acid 400g to the pulp in sequence / t, butylamine black medicine 300g / t and No. 2 oil 20g / t, the stirring time of each of the above medicines is 3 minutes; after mixing, enter the flotation tank for rough selection;

[0028] Scheme 2: The grinding fineness and dosage of chemicals are the sam...

Embodiment 2

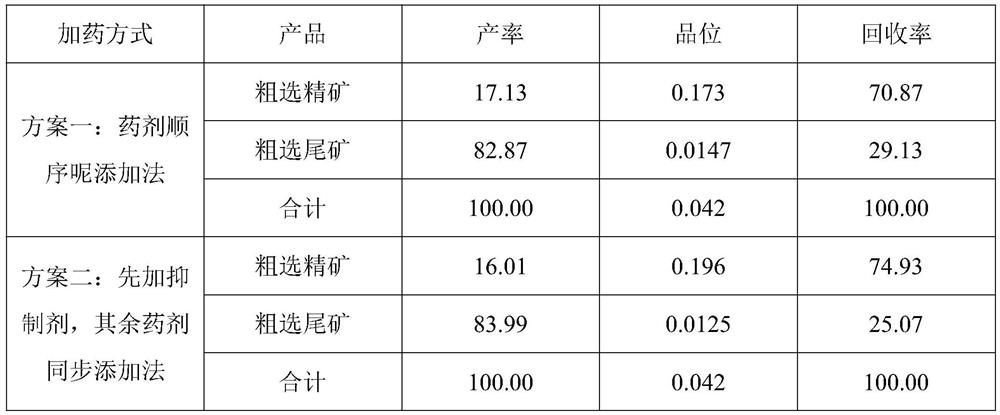

[0035] Gravity separation fine mud of an alkaline feldspar granite tantalum niobium ore in Jiangxi, in the fine mud (TaNb) 2 o 5 content of 0.0421%; the main tantalum-niobium minerals in the fine mud are tantalum-niobite, tantalum-niobium-manganese ore and fine spar; the gangue minerals are mainly albite, orthoclase, quartz, muscovite, etc.; the fine mud -0.038mm accounts for 80%, and -0.02mm accounts for 48%, so the flotation method is used to recover the fine mud.

[0036] Option 1: Sequential addition of agents: making pulp with fine mud with a concentration of 30%; sequentially adding sodium carbonate, acidified water glass 200g / t, carboxymethyl cellulose 200g / t, lead nitrate 300g / t, and benzene to the pulp 300g / t of hydroxamic acid, 200g / t of butyl xanthate and 20g / t of No. 2 oil, the stirring time of each of the above chemicals is 3 minutes; after pulping, enter the flotation tank for roughing;

[0037] Scheme 2: The grinding fineness and dosage of chemicals are the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com