Dust-free polishing device for castings

A polishing device and casting technology, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of breathing, uneven edges and corners, rough surfaces and other problems that affect the work, and achieve improvement The effect of work efficiency, reasonable design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

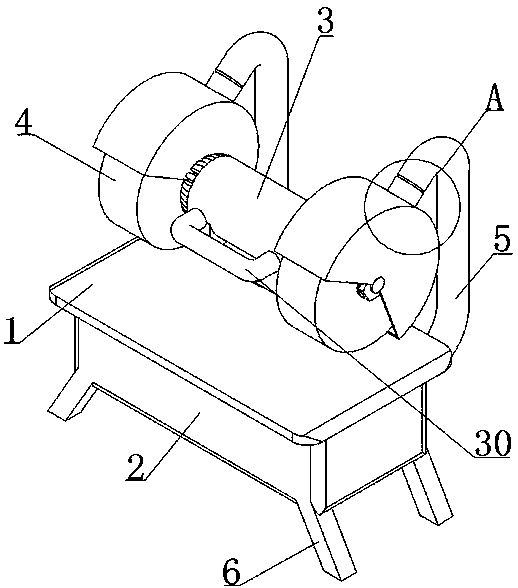

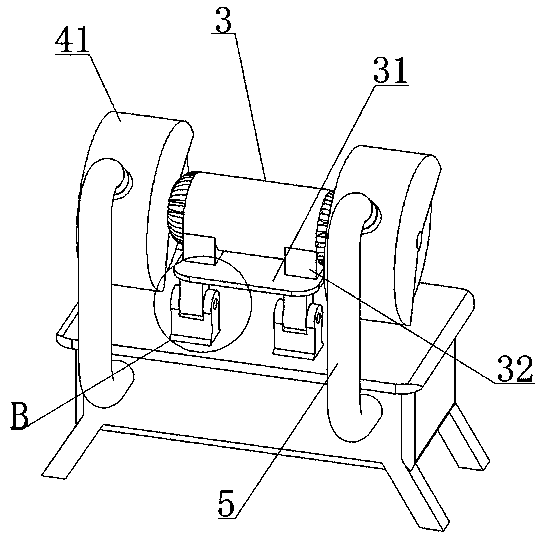

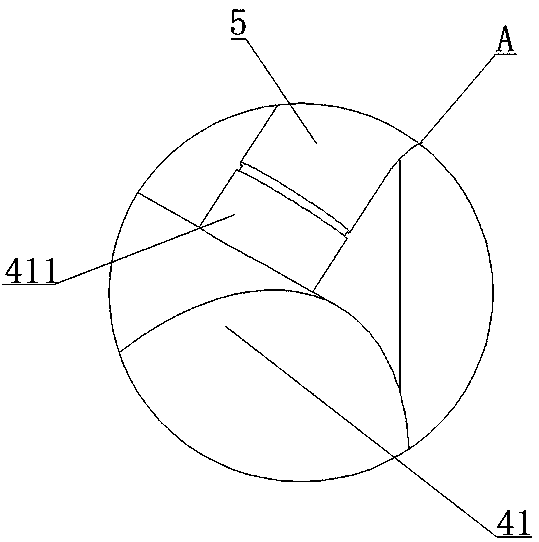

[0016] Such as Figure 1-4 As shown, the present invention is a dust-free polishing device for castings, including a workbench 1, a vacuum cleaner 2, a motor 3, a grinding wheel 4, a dust suction pipe 5 and a foot 6, and a vacuum cleaner 2 is fixedly connected directly below the workbench 1 , the four corners of the bottom of the vacuum cleaner 2 are fixedly connected with four legs 6. The upper surface of the workbench 1 is connected with a motor 3, and the two ends of the motor 3 are connected with a grinding wheel 4. The dust suction pipe 5 connects the vacuum cleaner 2 and the grinding wheel 4. The polishing device connected with this structure can absorb the dust generated during the polishing process to create a dust-free polishing environment. The dust generated by surface polishing will affect the health of the staff, and the grinding wheel 4 can be used in Rotation at a certain angle on the workbench 1 is convenient for staff to polish heavy castings, saves time and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com