Folding and conveying device and method for cigarette trademark inner frame paper

A technology of conveying device and inner frame paper, which is applied in the direction of transportation packaging, transportation and packaging, packaging material feeding device, etc., to achieve the effect of saving equipment investment, large promotion and application value, and promoting process development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

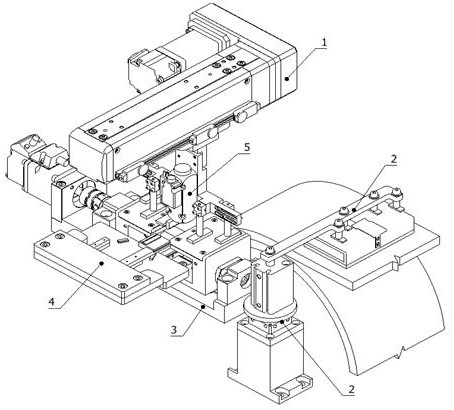

[0060] Below in conjunction with accompanying drawing and embodiment, the folding and conveying device and method of a kind of cigarette brand inner frame paper of the present invention will be further described:

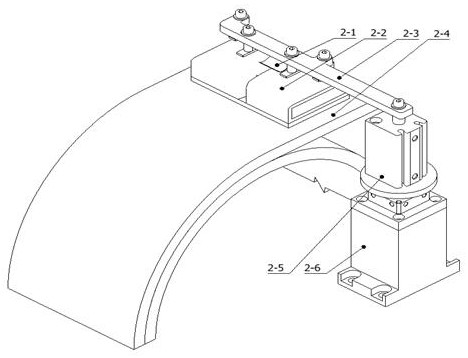

[0061] This device needs to be used in conjunction with the uvula cutter, which includes the uvula cutter back plate 4, the uvula fixed cutter 4-1, the fixed cutter back plate 4-2, the fixed cutter stop I4-3, the fixed cutter Block II 4-5, uvula cutter movable knife 4-7, the folding and conveying device of the inner frame paper of the cigarette brand includes a linear transmission module 1, a rotary suction transmission module 2, a folding base 3, and a suction folding claw 5; The uvula cutter back plate 4 is installed above the uvula fixed cutter 4-1.

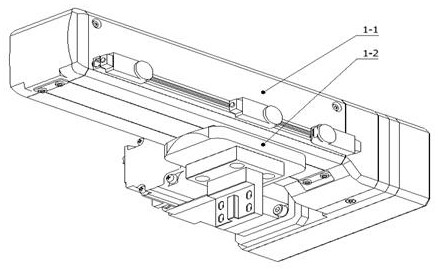

[0062] The suction folding claw 5 is assembled on the linear transmission guide rail slider 1-2 of the linear transmission module 1, the linear transmission module 1 is fixed on the external shelf, and the movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com