A high-efficiency anti-clogging scraper conveyor

A scraper conveyor and anti-clogging technology, applied in the field of conveyors, can solve the problems of reducing the later use effect of materials, reducing the efficiency of material conveying, and inability to screen and remove impurities, so as to avoid jamming, improve the use effect, and improve the conveying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

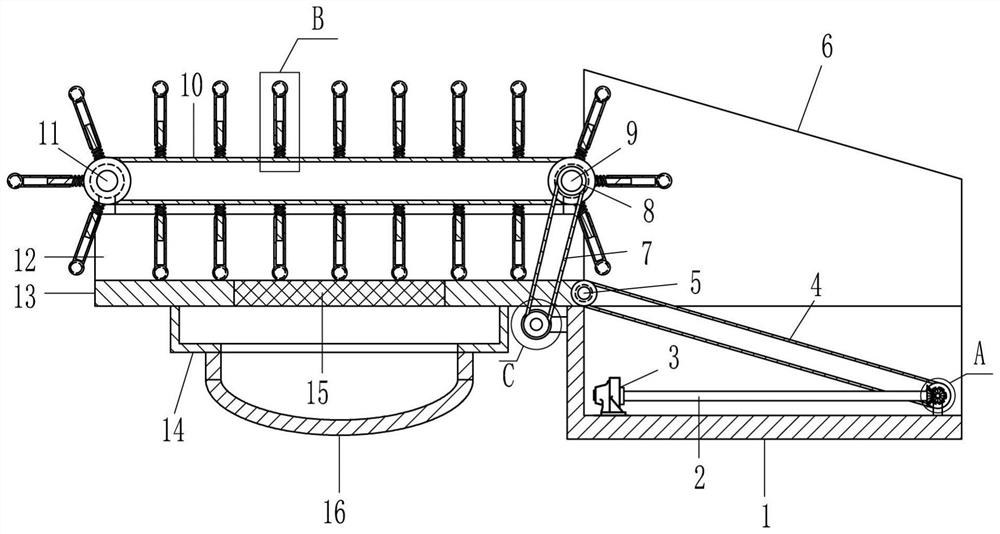

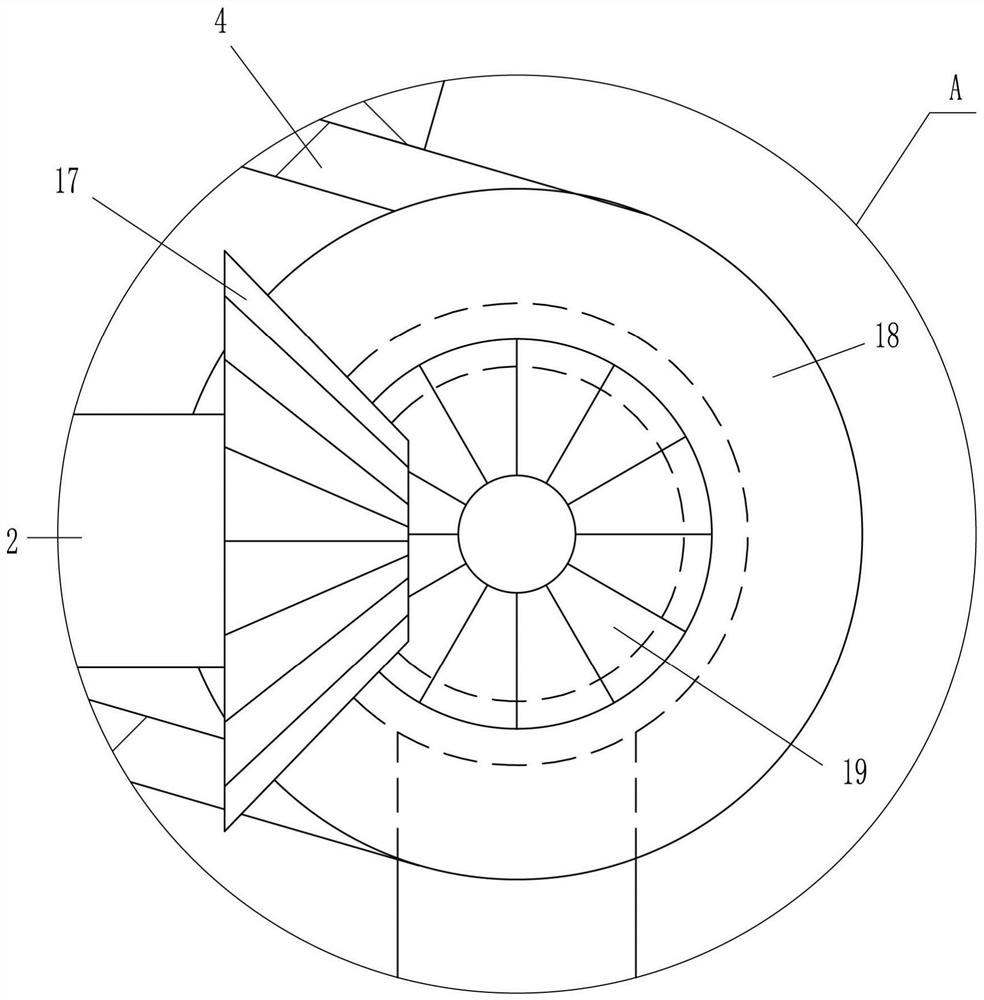

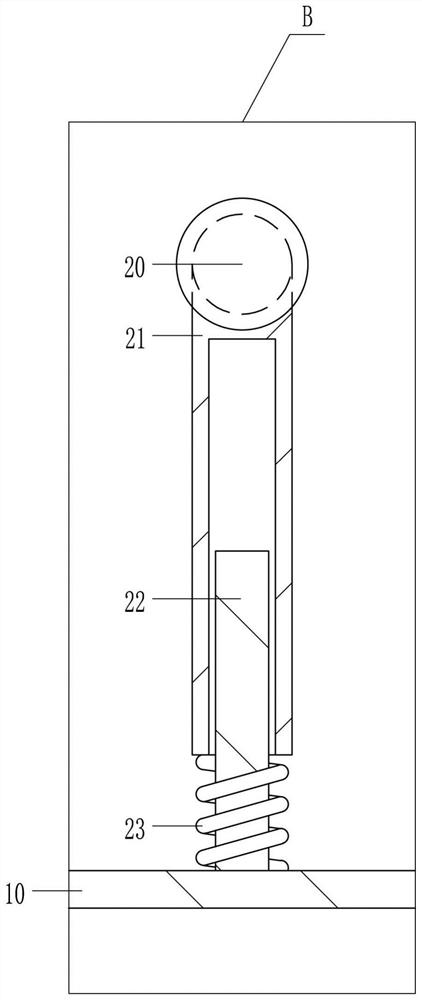

[0034] A high-efficiency anti-clogging scraper conveyor, such as Figure 1-12 As shown, it includes a feeding frame 1, a first rotating shaft 2, a driving motor 3, a feeding belt 4, a first rotating roller 5, a first transmission belt 7, a second rotating roller 9, a second transmission belt 10, and a third rotating roller 11. Conveyor frame 13, installation frame 14, screen 15, collection frame 16, first bevel gear 17, fourth rotating roller 18, second bevel gear 19, pusher roller 20, guide scraper 21, lifting plate 22, The first elastic member 23 and the driving wheel 24; the front and rear sides of the top of the loading frame 1 are fixedly connected with the first material retaining plate 6; the drive motor 3 and the fourth rotating roller 18 are installed on the inner bottom of the loading frame 1, and the first The rotating shaft 2 is connected to the output end of the drive motor 3 through transmission, the first bevel gear 17 is fixedly connected to the end of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com