A thermos bottle liner conveying and dumping device

A technology of pouring device and thermos bottle, which is applied in the direction of conveyor, transportation and packaging, conveyor objects, etc., which can solve the problems of waste of manpower, insufficient function and simplicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

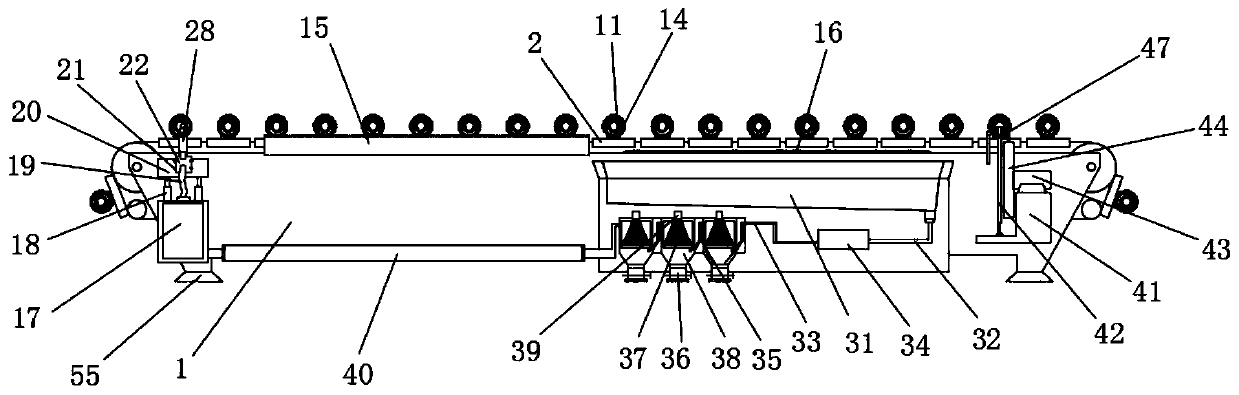

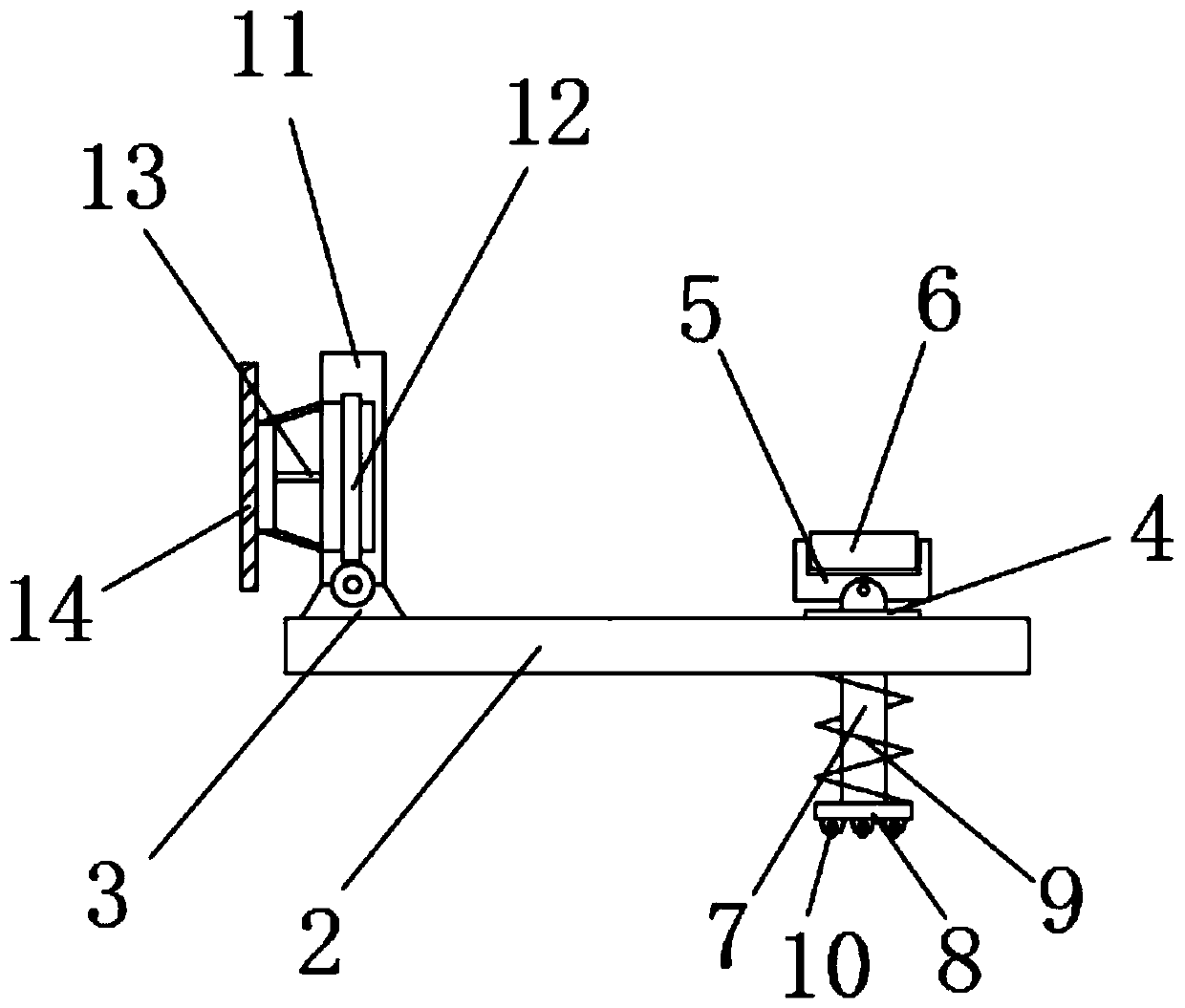

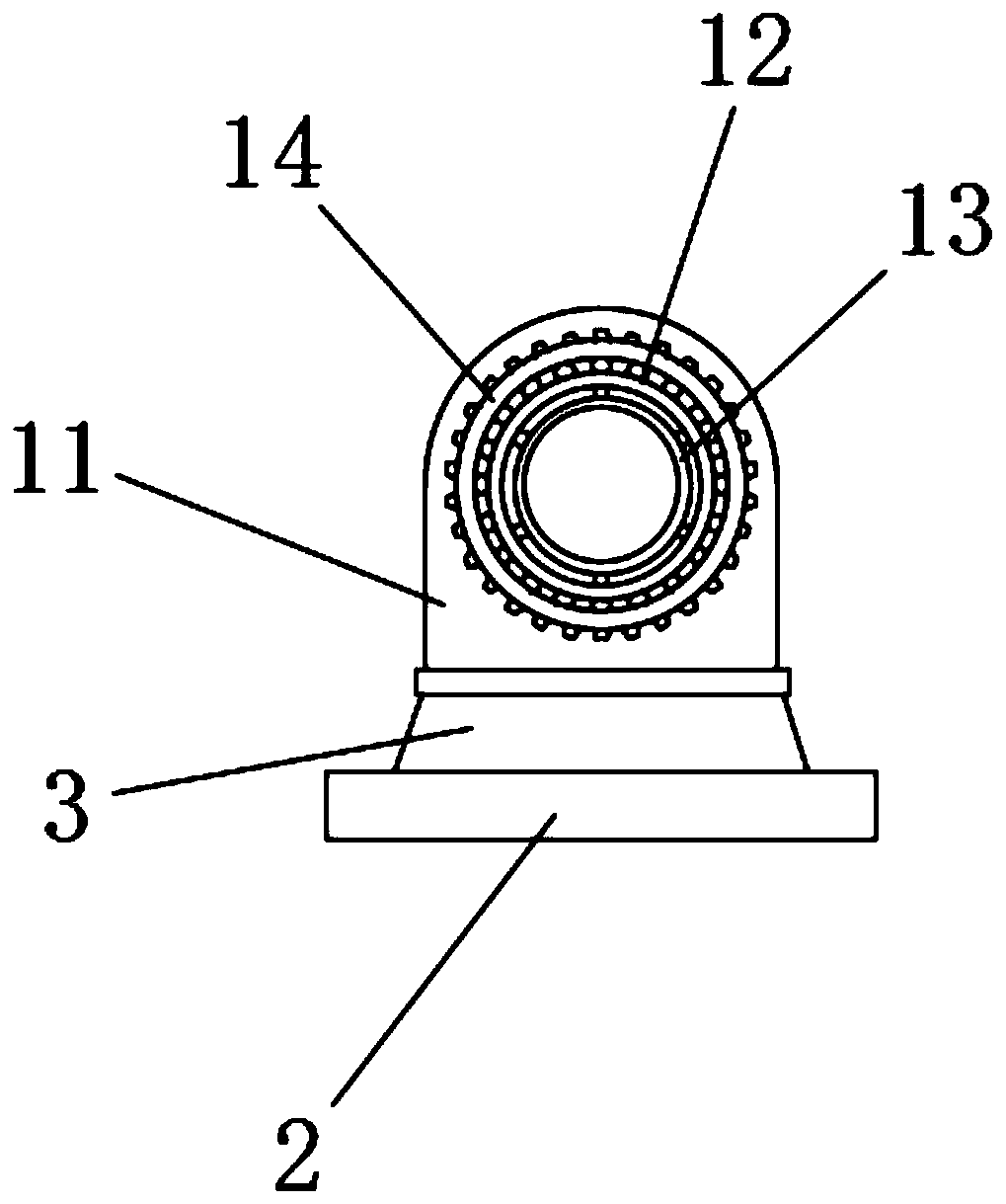

[0034] Embodiment 1: as Figure 1-13As shown, a thermos bottle liner conveying and dumping device includes a conveyor 1 and a chain plate 2, four sets of legs 55 are fixedly connected to the bottom of the conveyor 1, and several supporting wheels 54 are fixedly installed on the top of the conveyor 1 , the top and bottom of the conveyor 1 are provided with concave cavities 53, the top left side of the chain plate 2 is fixedly connected with a first base 3, and the top of the first base 3 is rotatably connected with a fixed frame 11 , the inner wall of the fixed frame 11 is fixedly equipped with a bearing 12, the inner wall of the bearing 12 is fixedly connected with a casing 13, the left side of the casing 13 is fixedly connected with a ring gear 14, and the right side of the chain plate 2 A strut 7 is movably connected through, the top of the strut 7 is fixedly connected with a second base 4, the top of the second base 4 is rotatably connected with a bracket 5, and the top of ...

Embodiment 2

[0038] Embodiment 2: as Figure 1-14 As shown, a thermos bottle liner conveying and dumping device includes a conveyor 1 and a chain plate 2, four sets of legs 55 are fixedly connected to the bottom of the conveyor 1, and several supporting wheels 54 are fixedly installed on the top of the conveyor 1 , the top and bottom of the conveyor 1 are provided with concave cavities 53, the top left side of the chain plate 2 is fixedly connected with a first base 3, and the top of the first base 3 is rotatably connected with a fixed frame 11 , the inner wall of the fixed frame 11 is fixedly equipped with a bearing 12, the inner wall of the bearing 12 is fixedly connected with a casing 13, the left side of the casing 13 is fixedly connected with a ring gear 14, and the right side of the chain plate 2 A strut 7 is movably connected through, the top of the strut 7 is fixedly connected with a second base 4, the top of the second base 4 is rotatably connected with a bracket 5, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com