Device for quick hot melt combination of soap residue and new soap

A soap and fast technology, applied in the field of daily utensils, can solve problems such as no better treatment method, and achieve the effects of saving soap, saving space and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

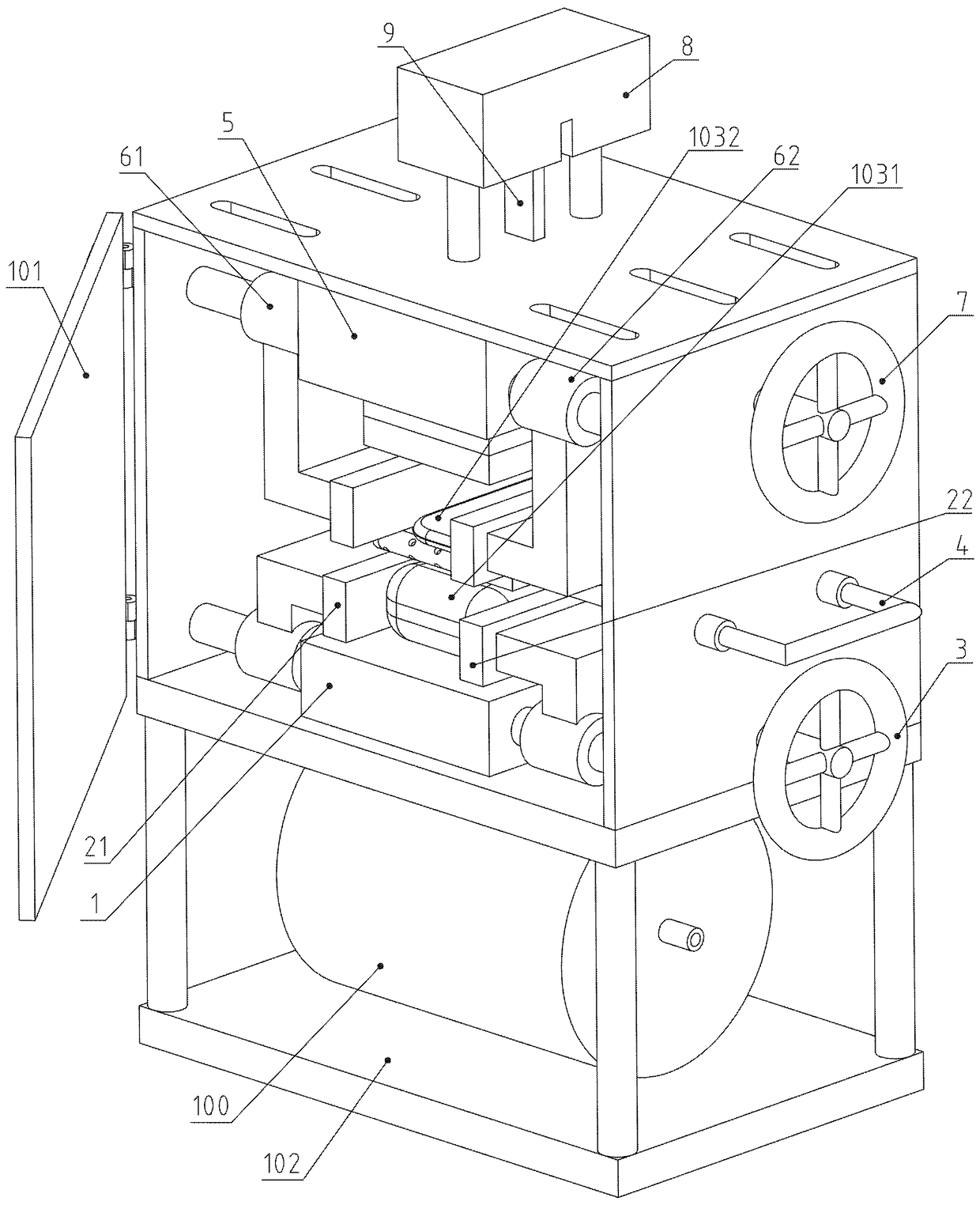

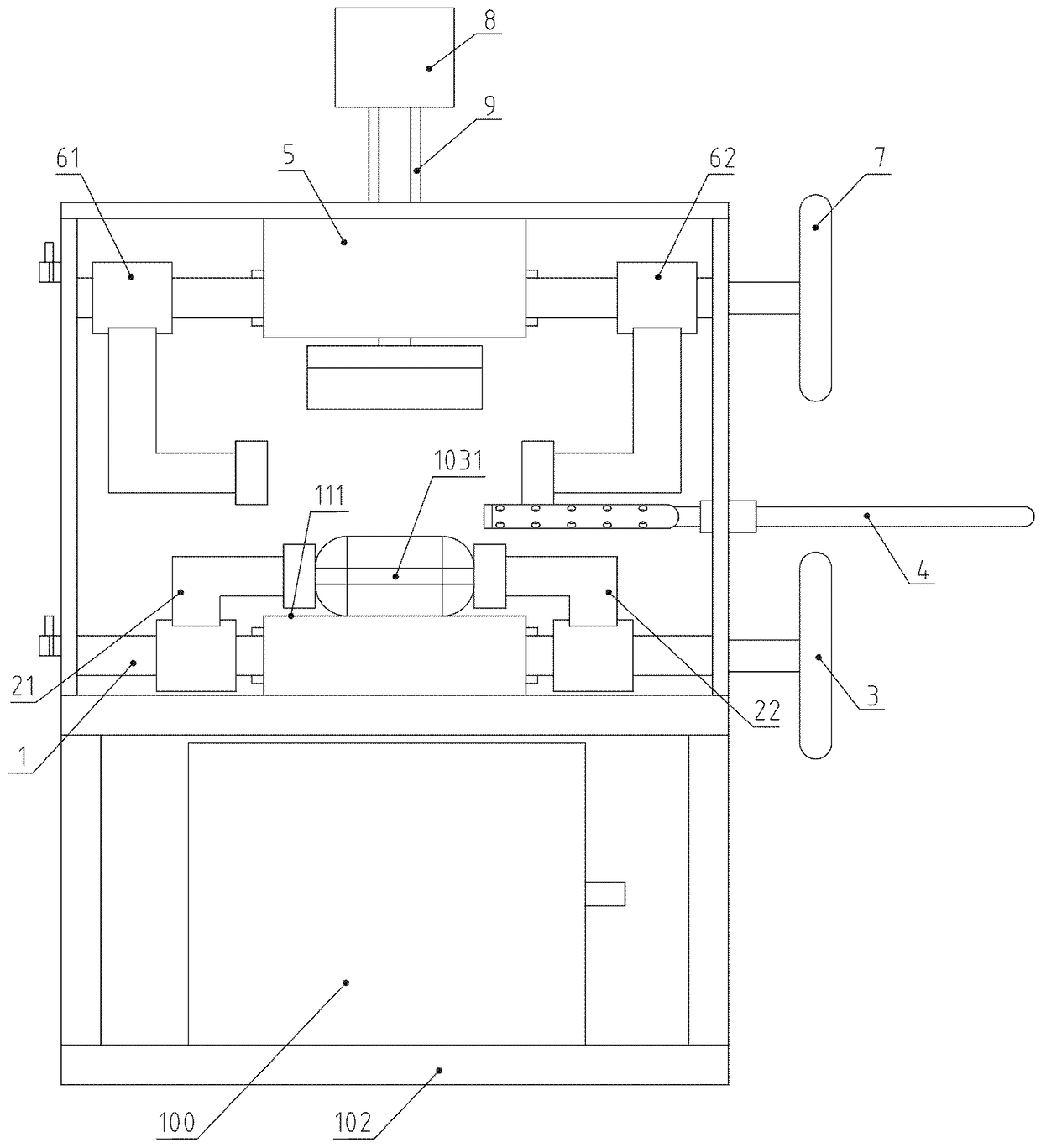

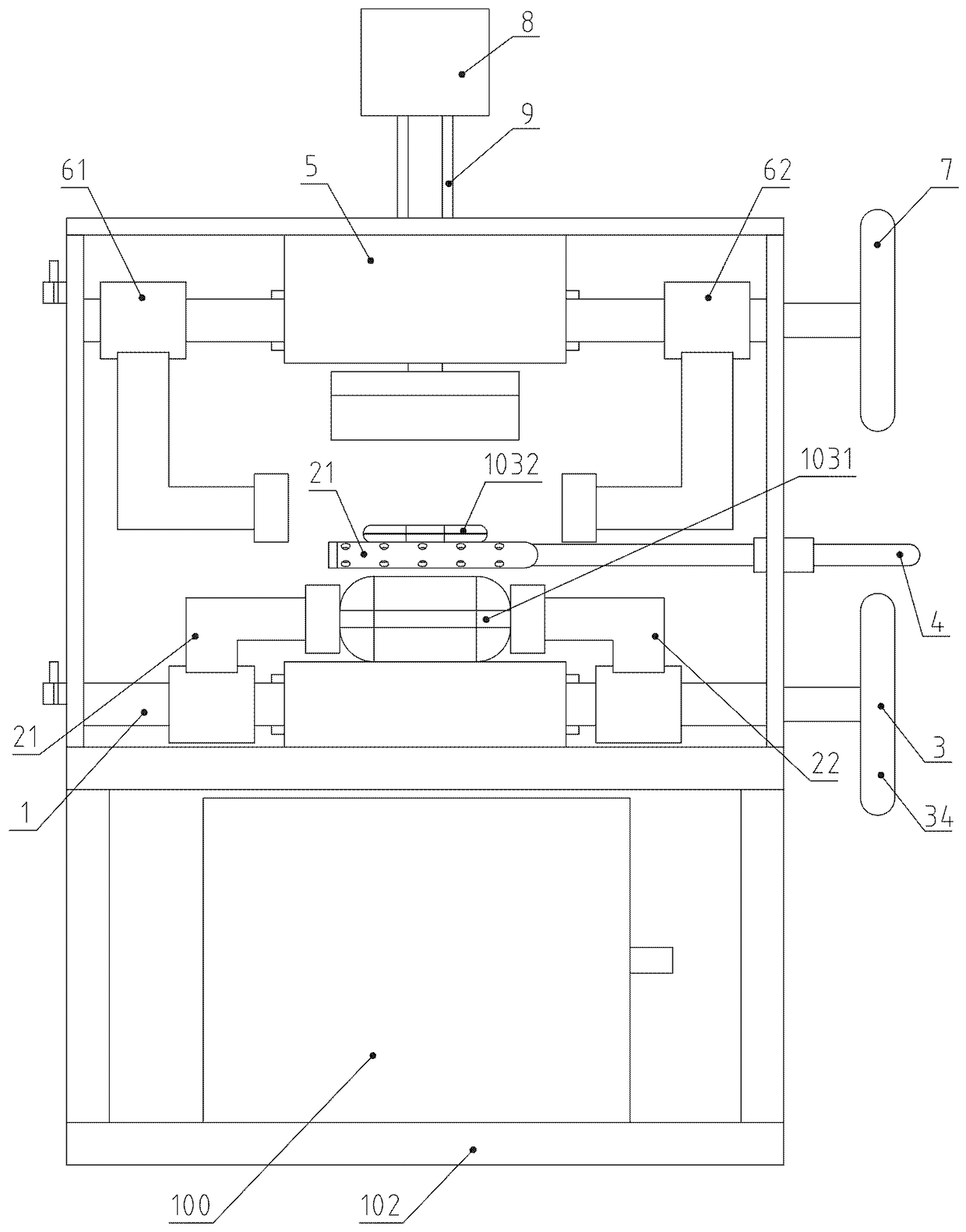

[0059] Example: see Figure 1 to Figure 22 .

[0060] A device for combining soap head and new soap by hot melting rapidly, comprising a lower guide rod assembly 1, a lower left push plate assembly 21, a lower right push plate assembly 22, a lower screw rod assembly 3, a grate assembly 4, an upper guide rod assembly 5, an upper left push plate assembly Push plate assembly 61, right upper push plate assembly 62, upper screw assembly 7, upper platen assembly 8, support plate 9, hot air assembly 100, door assembly 101 and support 102;

[0061] The support 102 comprises a base 1021, a middle plate 1022, a right wall plate 1023, a left wall plate 1024, a rear wall plate 1025 and a top plate 1026; the base 1021, the middle plate 1022 and the top plate 1026 are arranged horizontally, the base 1021 is below, and the top plate 1026 is on top. The middle plate 1022 is located between the base 1021 and the top plate 1026; the base 1021 and the middle plate 1022 are fixedly connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com