Needle plate structure for silk fabric printing and dyeing machine

A technology for printing and dyeing machines and silk fabrics, which is applied to general parts of printing machinery, printing machines, printing, etc. It can solve problems such as poor anti-vibration performance, easily damaged needle plate structure due to vibration, and steel needles touched by maintenance personnel. Excellent vibration performance, improved anti-vibration performance, and avoiding vibration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, but not as the basis for limiting the present invention.

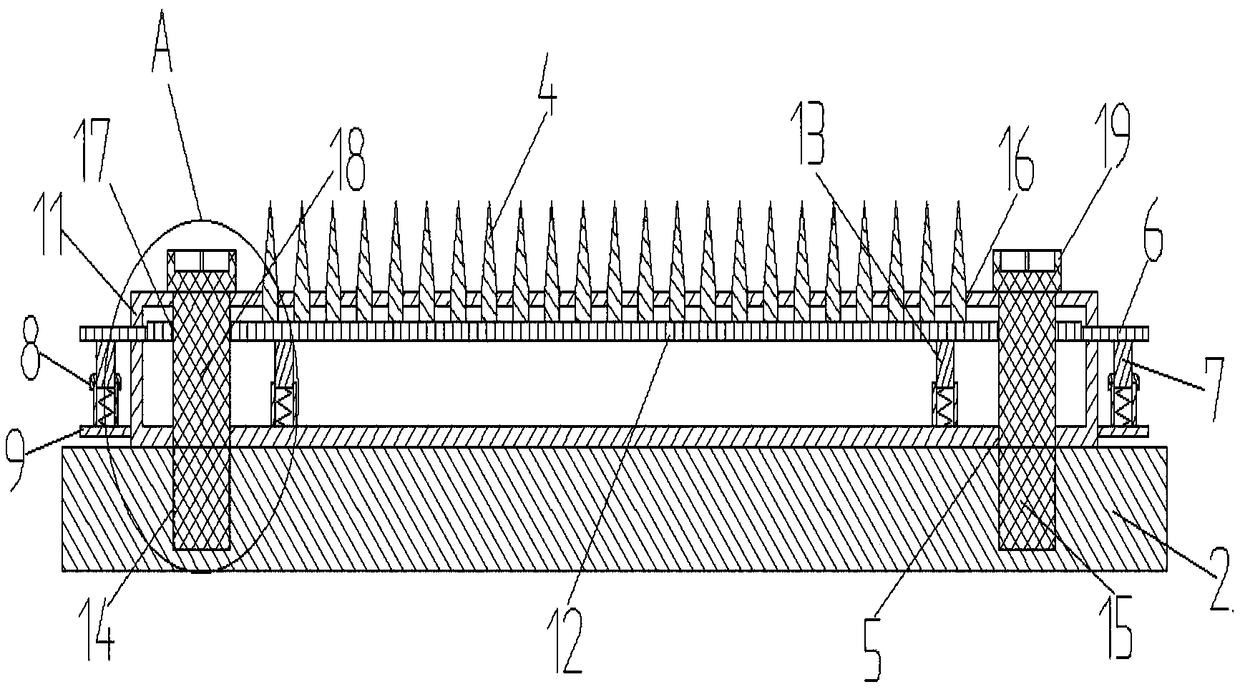

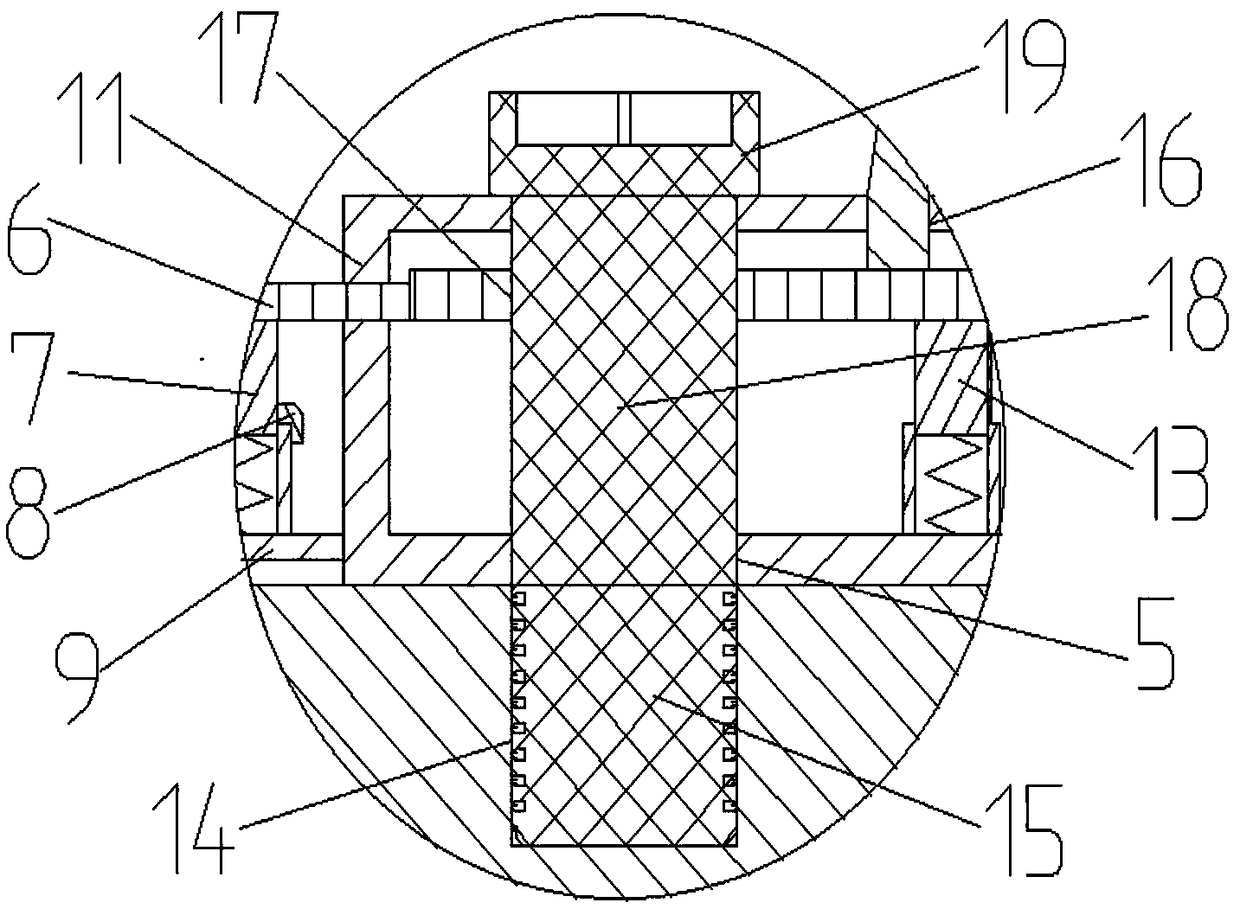

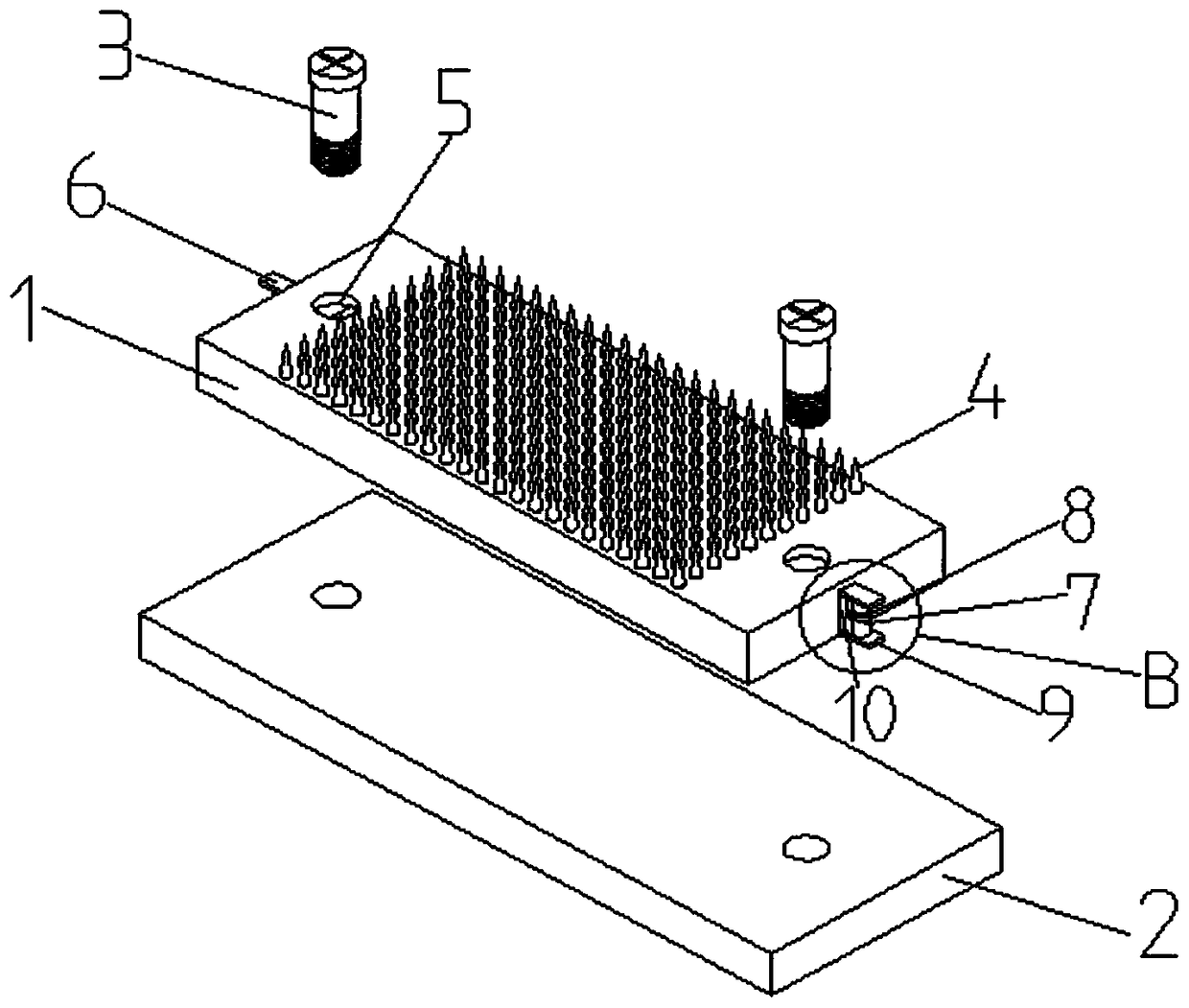

[0022] Example. The needle plate structure used in silk fabric printing and dyeing machine is as follows: Figure 1-4 As shown, it includes a needle plate 1, and a needle plate fixing seat 2 is arranged under the needle plate 1; the needle plate 1 includes a steel needle hollow plate 11, and a steel needle lifting plate 12 is arranged in the cavity of the steel needle hollow plate 11; The steel needle hollow plate 11 is provided with the first vertical through hole 5, the steel needle hollow plate 11 upper end is provided with a steel needle matching hole 16, and the steel needle hollow plate 11 left and right ends are all provided with a sliding through groove 10; The lifting plate 12 is provided with a second vertical through hole 17, the upper end of the steel needle lifting plate 12 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com