Dual mass flywheel

A dual-mass flywheel and mass flywheel technology is applied to flywheels, springs/shock absorbers, vibration suppression adjustments, etc., which can solve problems such as the inability to achieve the best shock absorption effect, limited service life of springs, and limited contact area. Good vibration effect, good elasticity effect, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

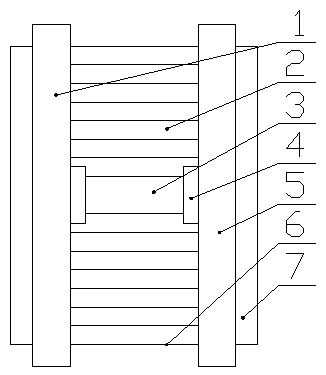

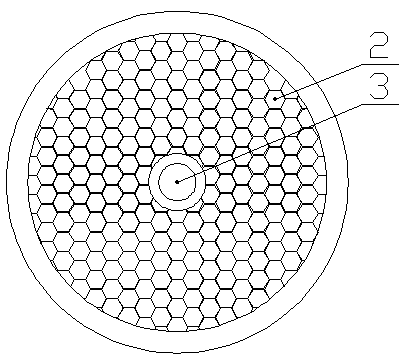

[0015] Such as figure 1 , figure 2 As shown, a dual-mass flywheel includes a first mass flywheel 1 and a second mass flywheel 5. The first mass flywheel 1 is connected to a drive shaft 3 through a bearing 4, and the other end of the drive shaft 3 passes through The bearing 4 is connected with the second mass flywheel 5, and the first mass flywheel 1 and the second mass flywheel 5 are fixed by a honeycomb rubber disc 6, and the honeycomb rubber disc 6 is connected with the first mass flywheel 1, the second mass flywheel 5 The two-mass flywheels are all connected by elastic joints 7, and the honeycomb rubber disc 6 is provided with tight honeycomb holes 2.

[0016] The invention connects the dual-mass flywheel through a honeycomb-shaped rubber disk, and the honeycomb-shaped rubber disk is provided with tight honeycomb holes. The mass flywheel is tightly and completely connected, and the contact area reaches the maximum, so that the dual-mass flywheel reduces vibration, and th...

Embodiment 2

[0018] Such as figure 1 , figure 2 As shown, a dual-mass flywheel includes a first mass flywheel 1 and a second mass flywheel 5. The first mass flywheel 1 is connected to a drive shaft 3 through a bearing 4, and the other end of the drive shaft 3 passes through The bearing 4 is connected with the second mass flywheel 5, and the first mass flywheel 1 and the second mass flywheel 5 are fixed by a honeycomb rubber disc 6, and the honeycomb rubber disc 6 is connected with the first mass flywheel 1, the second mass flywheel 5 The two-mass flywheels are all connected by elastic joints 7, and the honeycomb rubber disc 6 is provided with tight honeycomb holes 2, and the honeycomb rubber disc 6 is flexibly connected to the first mass flywheel 1, so that The honeycomb rubber disc 6 and the second mass flywheel 5 are flexibly connected, the elastic joint 7 can be a rubber joint or a bellows, and the honeycomb hole 2 is closely arranged on the periphery of the drive shaft 3 .

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com