Annular nozzle propeller

An annular nozzle and thruster technology, applied in the aerospace field, can solve problems such as low efficiency, small fuel combustion space, and reduced combustion efficiency, and achieve the effects of improving efficiency, increasing fuel combustion space, and reducing projected area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

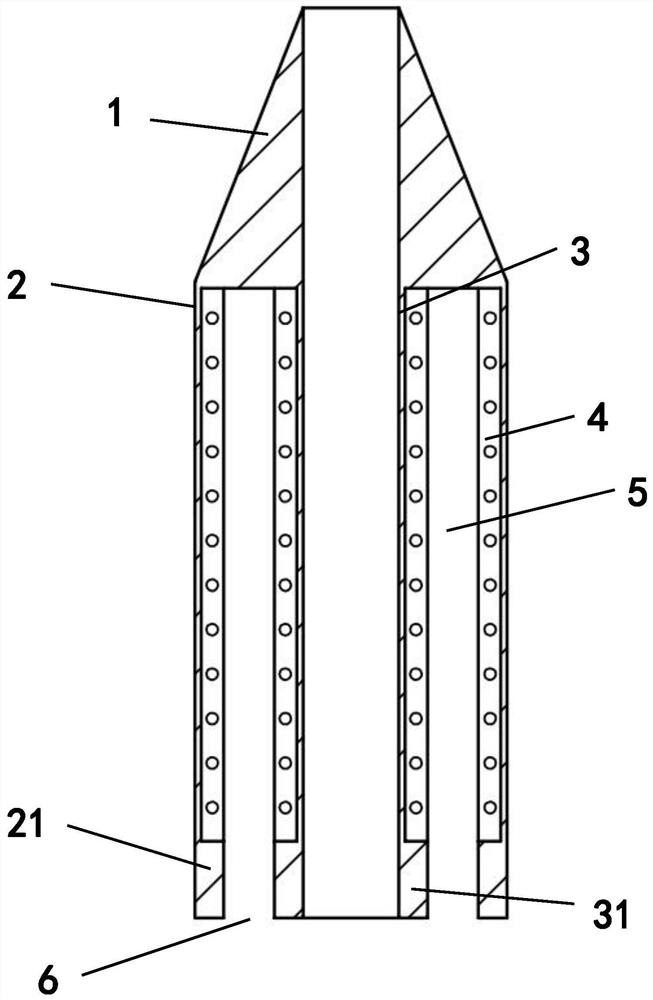

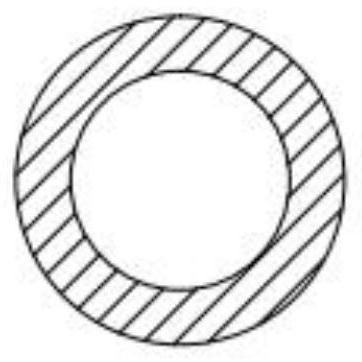

[0019] Such as figure 1 As shown, the annular nozzle propeller includes a fairing 1, a propeller casing 2, a solid fuel chamber and a solid fuel 4 arranged in the solid fuel chamber, and is characterized in that: it also includes a coaxial arrangement with the propeller casing 2. The cylindrical propeller inner shell 3, the upper edge of the propeller inner shell 3 is sealingly connected with the upper edge of the propeller outer shell 2, and the solid fuel chamber is between the propeller outer shell 2 and the propeller inner shell 3 A ring-shaped fuel chamber is formed between them, the gap between the lower edge of the propeller inner shell 3 and the lower edge of the propeller outer shell 2 forms an annular nozzle 6, and the lower edge of the propeller inner shell 3 is thickened and extended radially outward to form a The inner wall 31 of the nozzle, the lower edge of the propeller casing is thickened radially inward to form the outer wall 21 of the nozzle, the interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com