Heat exchange module and heat exchanger

A technology of heat exchange modules and heat exchangers, applied in indirect heat exchangers, heat transfer modification, heat exchange equipment, etc. problems such as full play and low heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

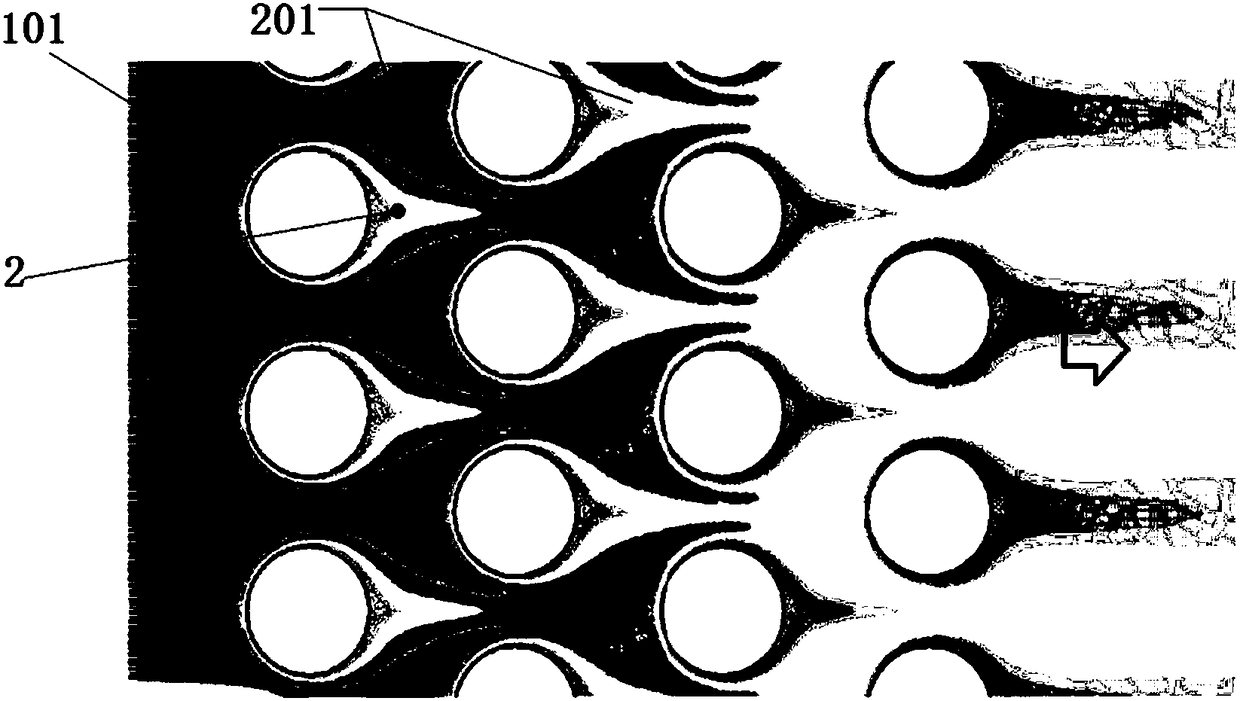

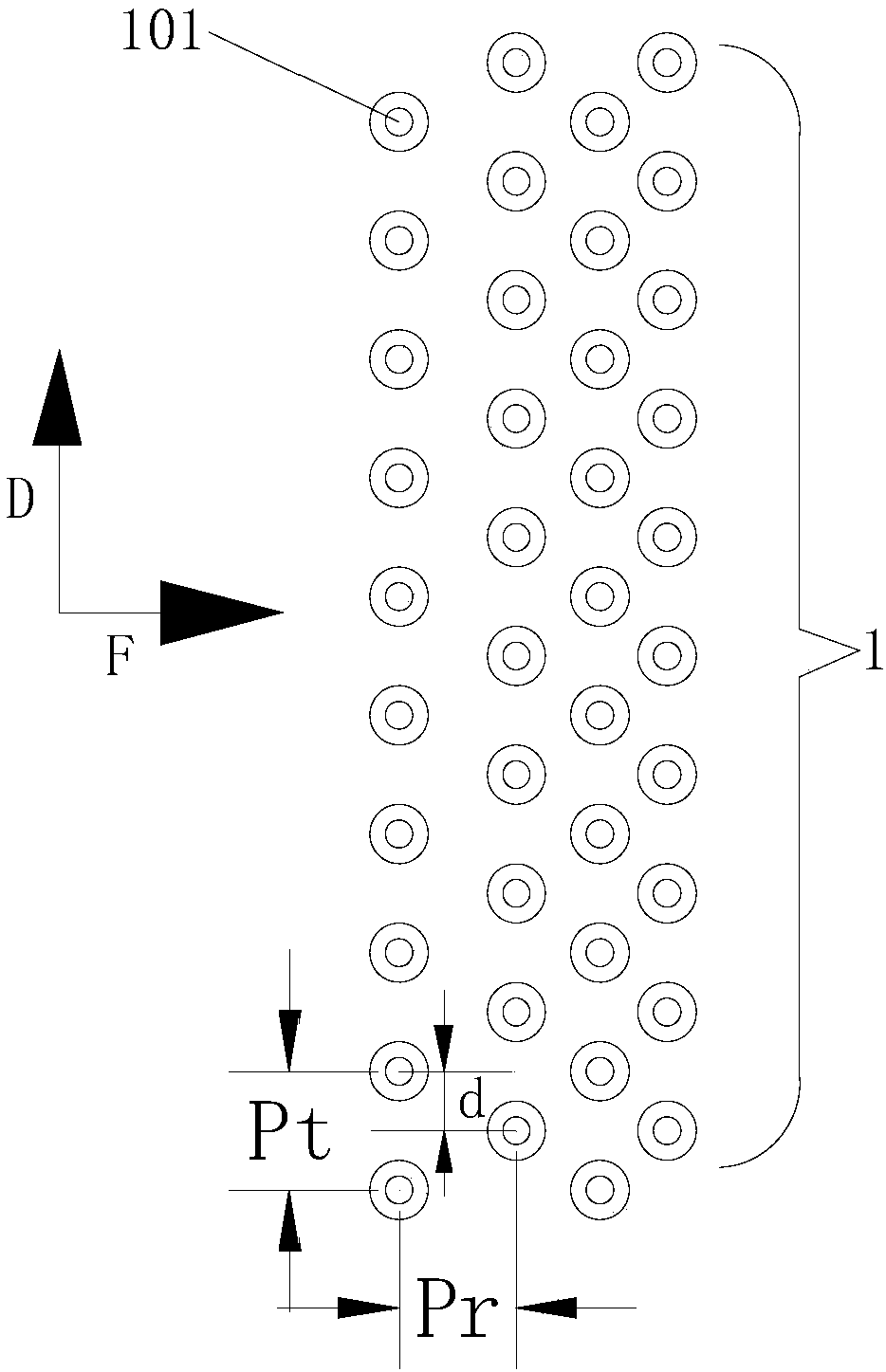

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] In the present invention, unless stated otherwise, the used orientation words such as "up, down, left, right" generally refer to the directions shown in the drawings or to vertical, perpendicular or gravity The terms used to describe the mutual positional relationship of each component in terms of direction.

[0025] In addition, the "front row and rear row" in the present invention mean "front and rear" with respect to the flow direction of the external heat exchange fluid. Here, "front row and rear row" should be understood as relative concepts, that is, among the two adjacent rows of microtube groups along the flow direction of the external heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com