Stress corrosion high-flux evaluation method based on multi-section sample

A technology of stress corrosion and evaluation method, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, using stable tension/pressure to test the strength of materials, etc. problems, to achieve the effect of improving the test efficiency and shortening the test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

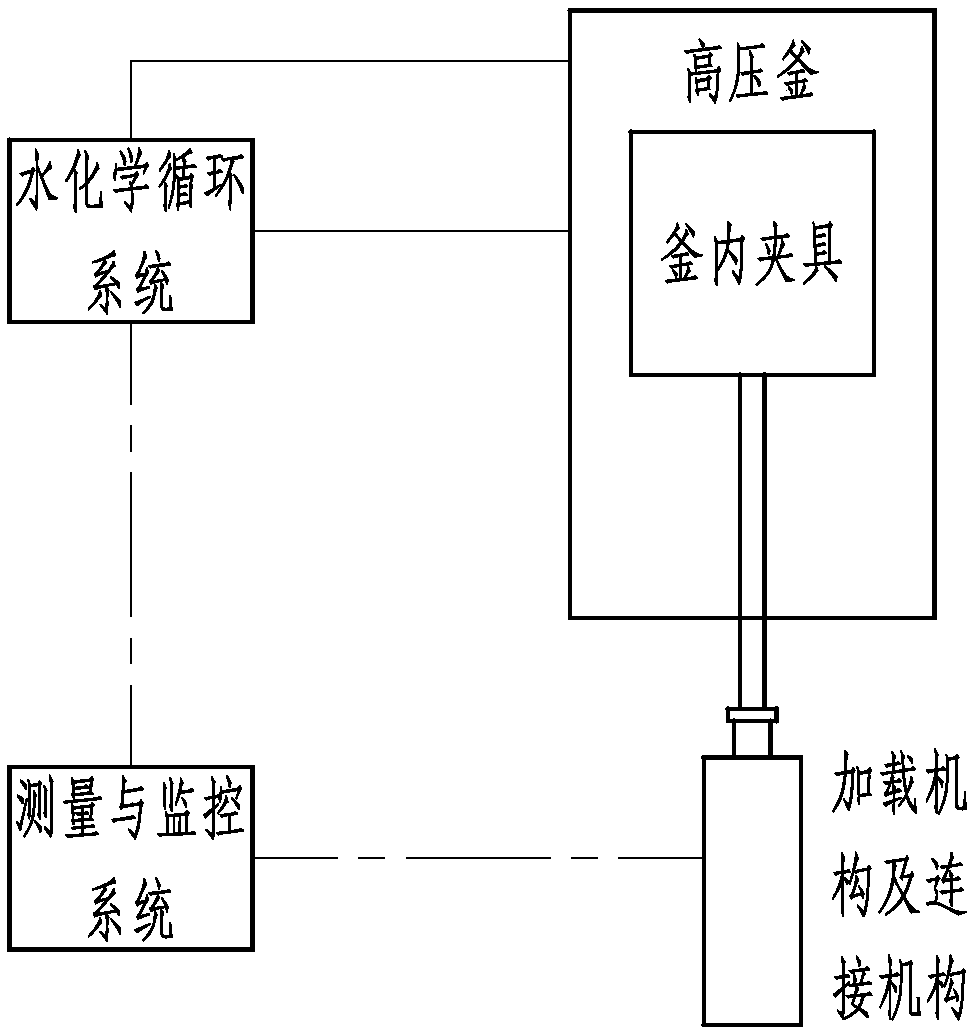

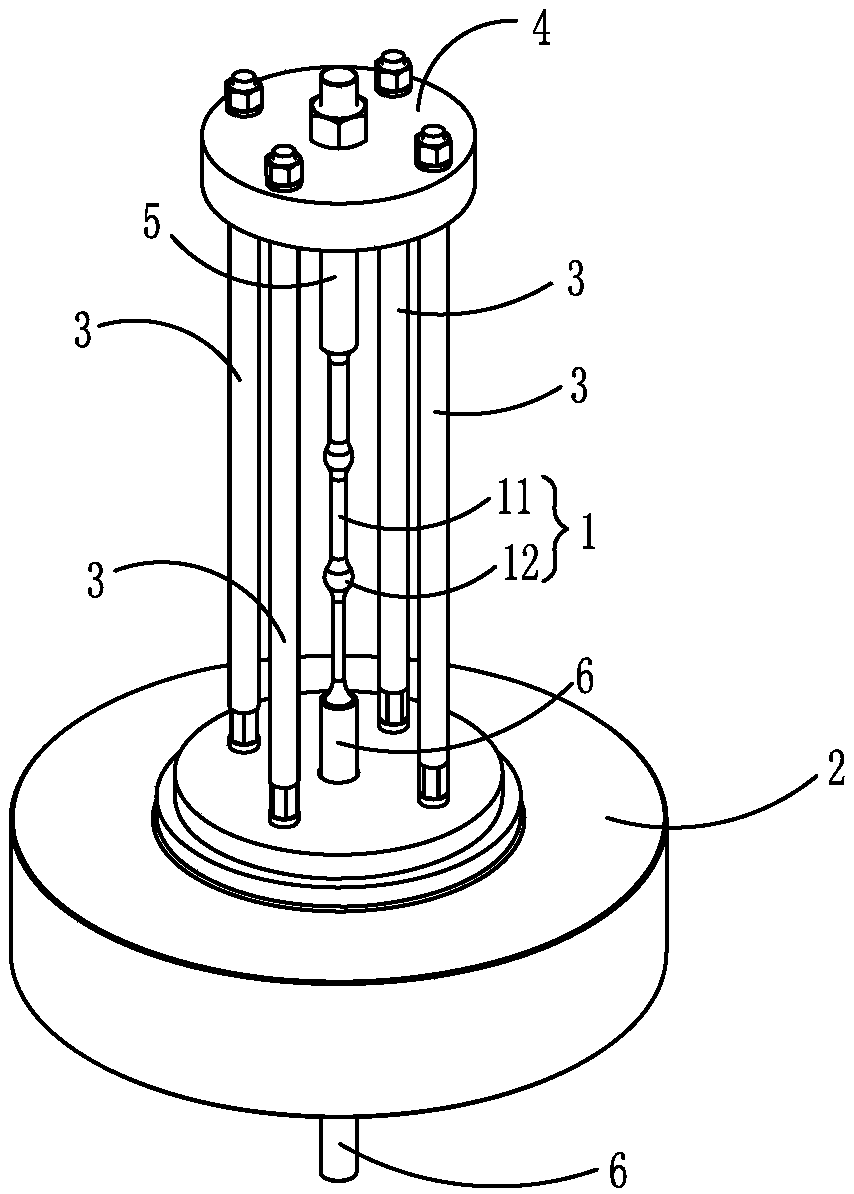

[0025] A high-throughput evaluation method for stress corrosion corrosion based on multi-section samples, using figure 1 The test device includes an autoclave and a test device. The test device includes a connecting mechanism for fixing the sample 1, a loading mechanism for loading stress on the sample 1 on the connecting mechanism, a measuring device for measuring the stress corrosion data of the test piece, and a driving high-pressure A hydrochemical circulation system in which the water in the kettle is circulated in the autoclave, and a monitoring system for controlling the loading mechanism and the measuring device, including the following steps:

[0026] 1) A rod-shaped sample 1 has fixing parts at both ends, and a plurality of test unit sections 11 with the same cross-sectional shape are processed along the length direction of the sample 1 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com