A forward and reverse switching device and a single-phase series motor

A switching device, forward and reverse technology, used in electromechanical devices, electrical components, DC commutators, etc., can solve problems such as influence, bending deformation, and inability to accurately and quickly reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

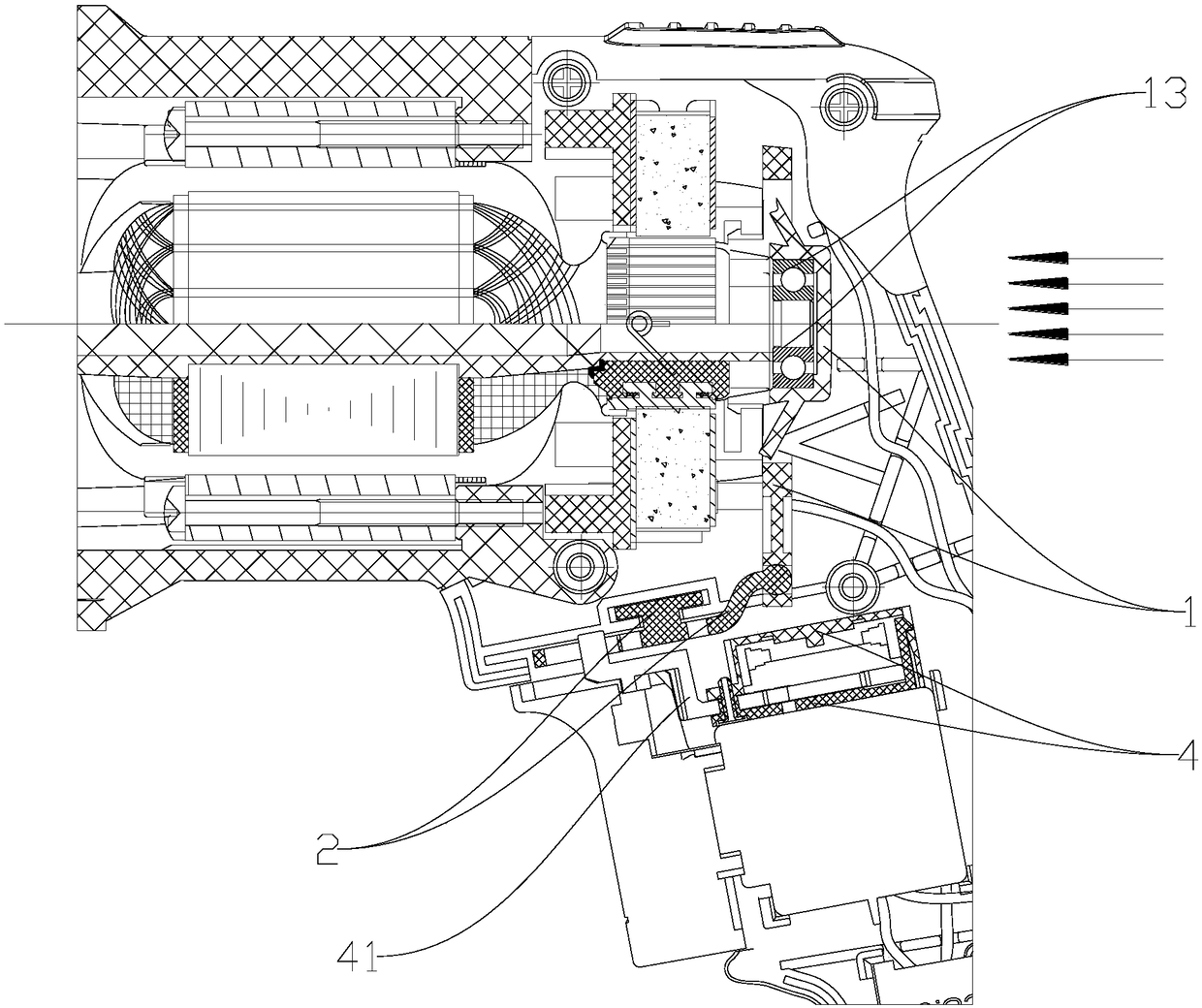

[0042] The core of the present invention is to provide a forward and reverse switching device, which improves the trigger structure of the forward and reverse components, and does not need to be arranged at the air inlet, so as to avoid the influence of the impurities in the intake air on the forward and reverse switch components.

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the forward and reverse switching device and the single-phase series motor of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

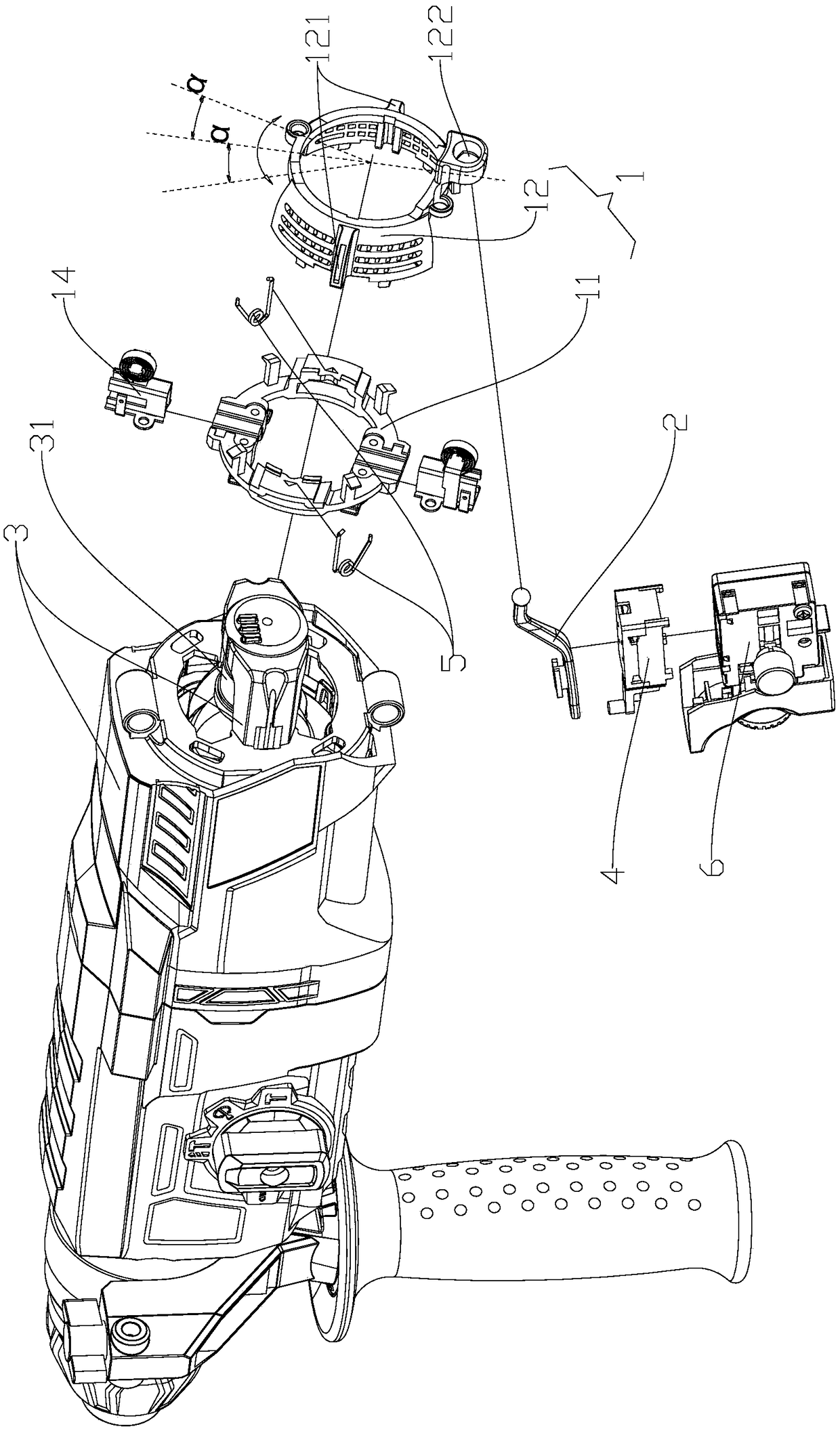

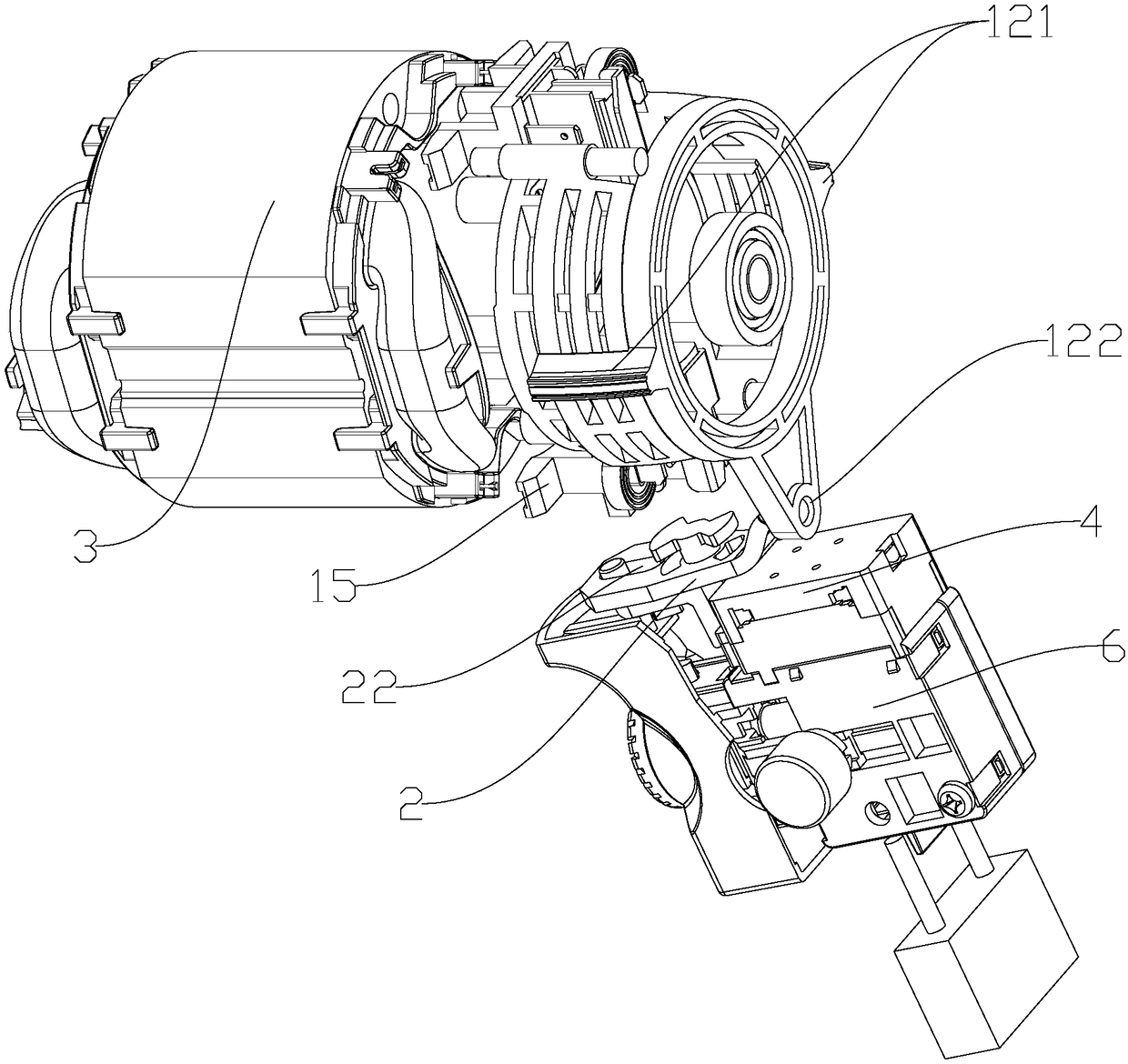

[0044] Such as Figure 1A As shown, it is an exploded view of the relative positions of each component of the forward and reverse switching device provided by the present invention and the motor, Figure 1B The overall structural diagram of the mutual assembly of the forward and reverse switching device and the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com