Material construction improvement of architectural cover plates comprehensive in performances

A comprehensive performance and architectural technology, applied in building construction, construction, roof insulation materials, etc., can solve the problems of increasing cost, energy consumption, increasing exhaust gas emission speed, etc., to achieve the effect of good windproof and better comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

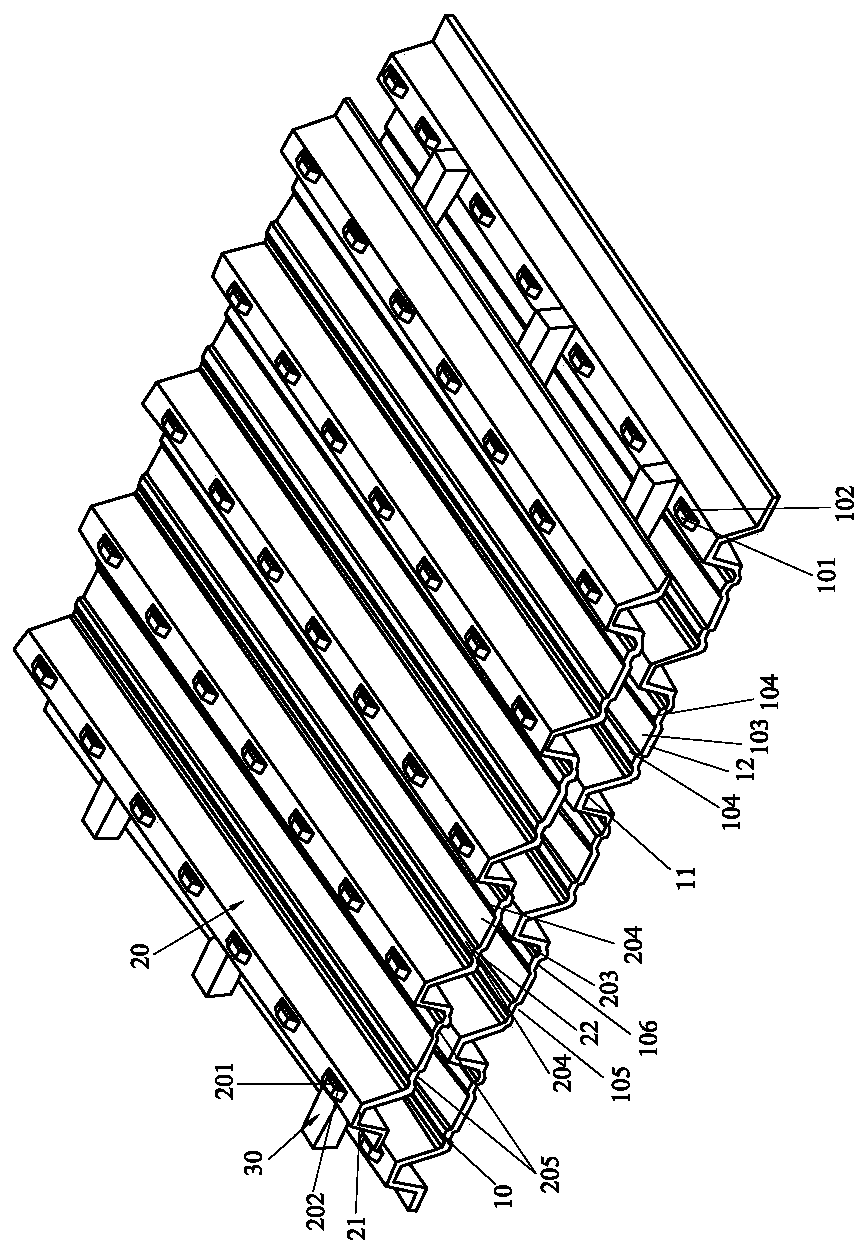

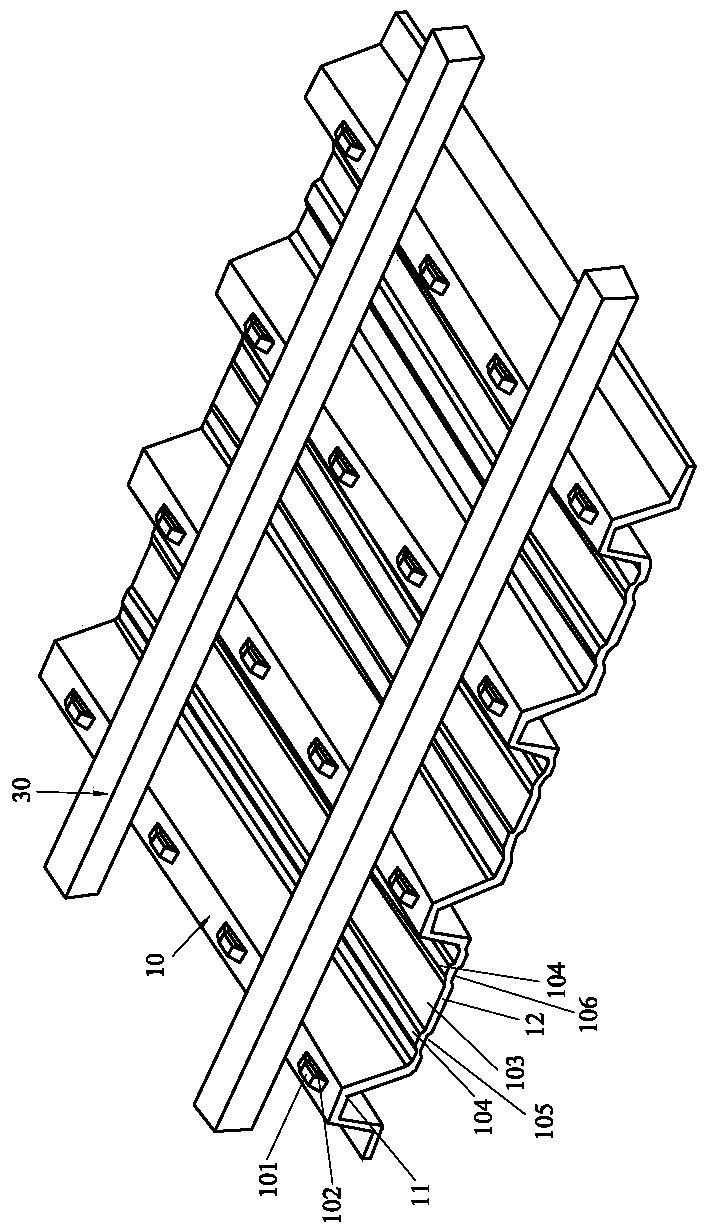

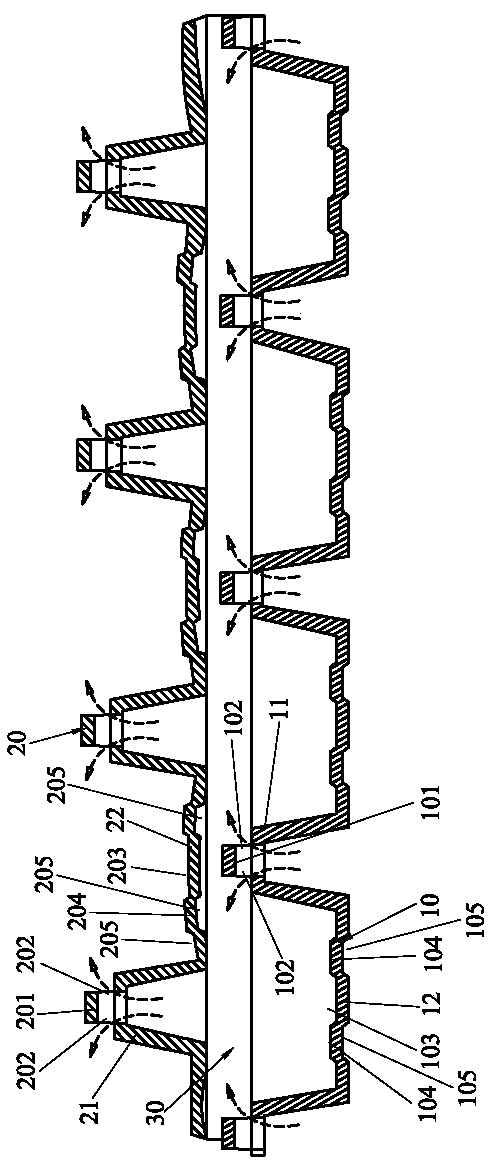

[0028] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, using the first building cover plate 10 and the second building cover plate 20 .

[0029] The first building cover plate 10 includes a plurality of first crests 11 and a plurality of first troughs 12 that are integrally formed and connected alternately and sequentially; each first crest 11 is punched and stretched from inside to outside to form a plurality of The first cover sheet 101, a plurality of first cover sheets 101 are arranged at intervals along the extension direction of the first peak portion 11 and protrude from the outer surface of the first peak portion 11, and each first cover sheet 101 is formed on both sides The first air convection hole 102 communicates with the inner and outer surfaces of the first peak portion 11 , and the shape and size of the first air convection hole 102 are not limited.

[0030] The second buildin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com