Method for controlling electric steam box and electric steam box

A control method and technology of an electric steamer, which are applied in the directions of steam cooking utensils, cooking utensils, household appliances, etc., can solve the problems of complex structure, water residue, bacterial growth, etc. of the electric steamer, so as to eliminate the phenomenon of residual water and reduce the production cost. , the effect of optimizing the structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

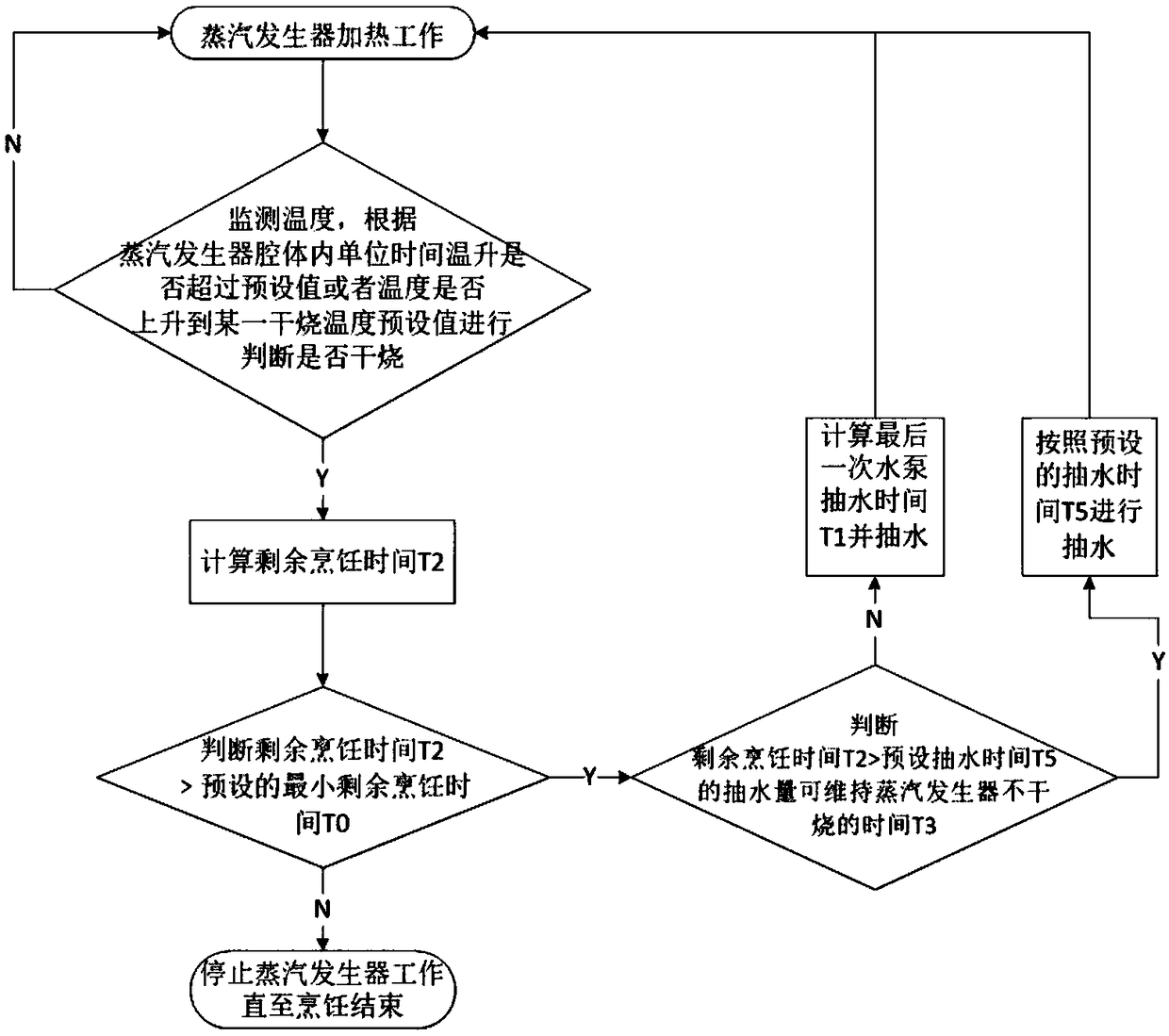

[0030] Embodiment one: if figure 1 Shown is a schematic flow chart of the electric steamer control method in the first embodiment. The electric steamer control method specifically includes:

[0031] The steam generator is powered on for heating to heat and evaporate the water in the cavity of the steam generator.

[0032] Determine whether the water in the steam generator cavity is used up and is in a dry-boiling state. If the temperature rise in the steam generator cavity per unit time has not exceeded the preset value or the temperature has not risen to a certain dry-boiling temperature preset value (two of them If any one of the conditions is satisfied), it is judged that the water in the steam generator cavity has not been used up and has not entered the dry burning state, and the steam generator continues to work; if the temperature rise in the steam generator cavity per unit time exceeds the preset value or the temperature rises to a preset value of the dry-boiling temp...

Embodiment 2

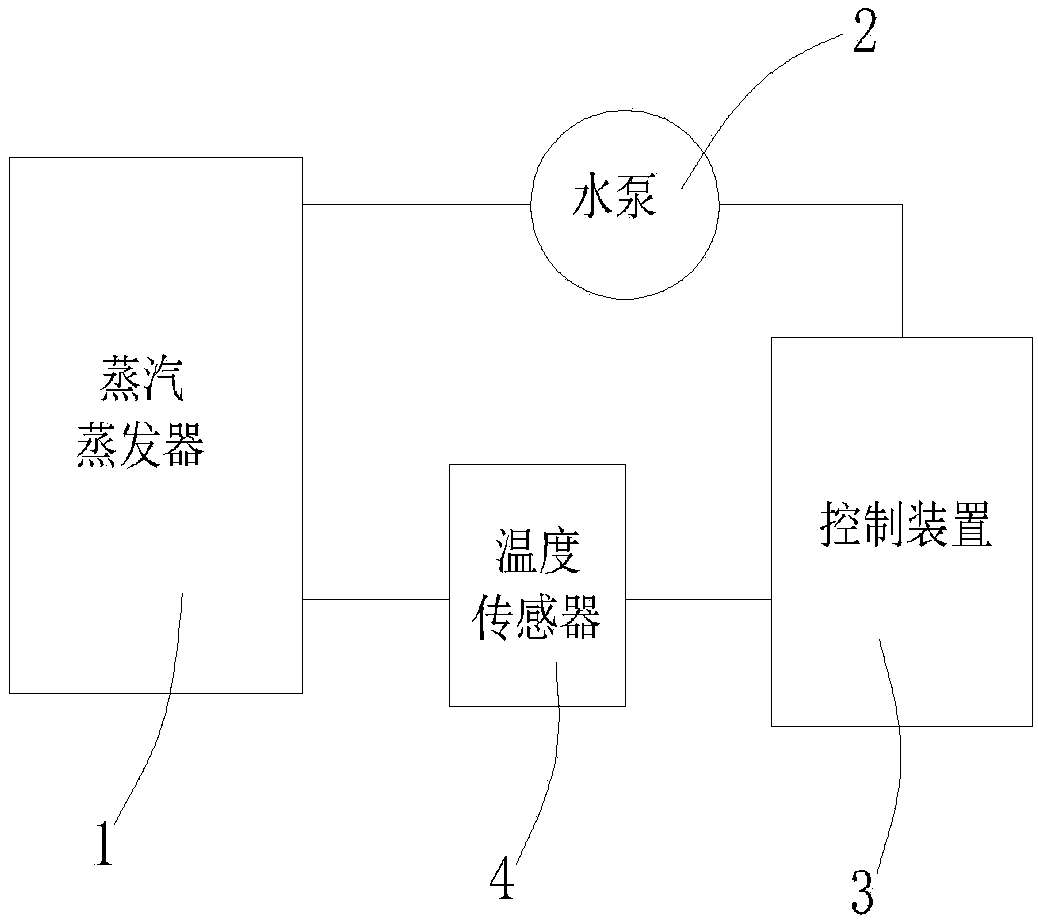

[0044] Embodiment two: if figure 2 Shown is a block diagram of the electric steamer in Embodiment 2 of the present invention, which may include: a steam generator 1 , a water pump 2 , a control device 3 , and a temperature sensor 4 .

[0045] The steam generator 1 is arranged in the electric steam box and is used for heating to generate steam.

[0046] The water pump 2 is arranged in the electric steamer, and it is connected with the steam generator 1 to supply water to the steam generator 1 .

[0047] The control device 3 is electrically connected with the steam generator 1 and the water pump 2 respectively. The control device 3 is used to judge whether the water in the cavity of the steam generator 1 is used up for dry boiling and calculate the remaining cooking time T2. According to the calculated remaining cooking time T2 It is decided to heat the steam generator 1 by pumping water or stop the steam generator 1 from working until the cooking is finished.

[0048] The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com