A tandem partitioned slit temperature detection device for container stacking

A detection device and container technology, applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of inability to arrange the inside of the stack, manual insertion of detection tubes, and unsuitable detectors and other problems, to achieve good application prospects, convenient operation, and improve the adaptability of the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

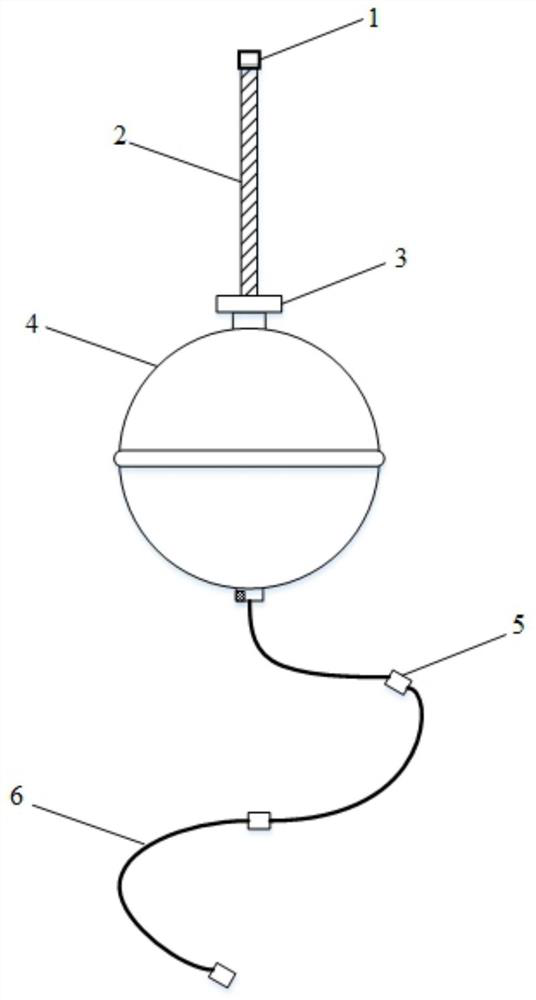

[0035] A tandem partitioned slit temperature detection device for container stacking, refer to figure 1 , comprising a sealed thick-walled ball 4, a bundled flexible thermocouple wire 6 connected to the sealed thick-walled ball 4, an operating switch 10 arranged at the junction of the bundled flexible thermocouple wire 6 and the sealed thick-walled ball 4, and arranged on the bundled flexible thermocouple wire 6 The temperature measuring node probes 5 at different heights, the transmission antenna 2 connected to the other side of the sealed thick-walled ball 4 , the clamping table 3 arranged on the upper end of the sealed thick-walled ball 4 , and the flash lamp 1 arranged on the top of the transmission antenna 2 .

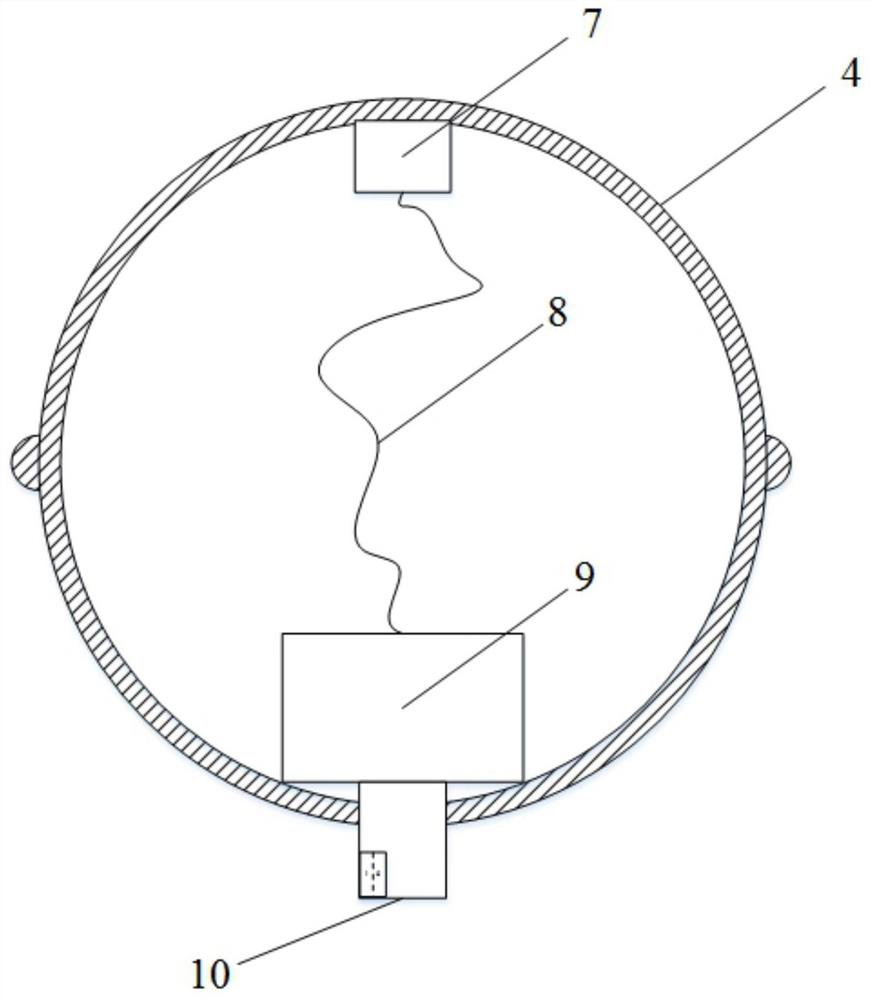

[0036] Such as figure 2 As shown, the sealed thick-walled ball 4 includes a battery compartment 9 arranged at the lower part of the sphere, a signal processor 7 arranged at the upper part of the sphere, a transmission line 8 and an operating switch 10. In actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com