Distributed fiber laser monitoring system and monitoring method

A distributed optical fiber and fiber laser technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of difficulty in finding faults, difficult to locate background faults, etc., and achieve the effect of solving missed detection and detection and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

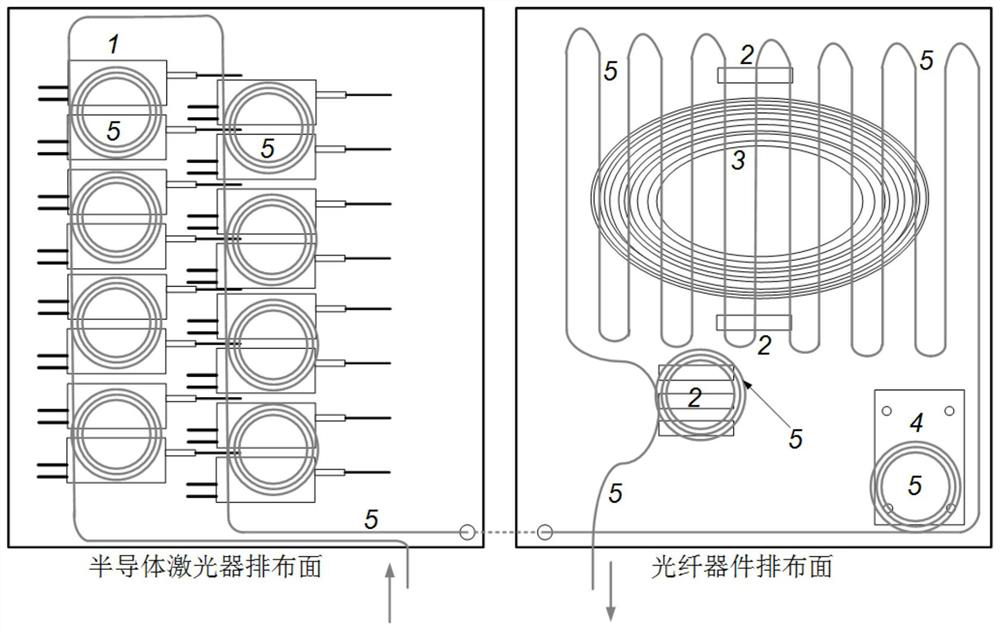

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

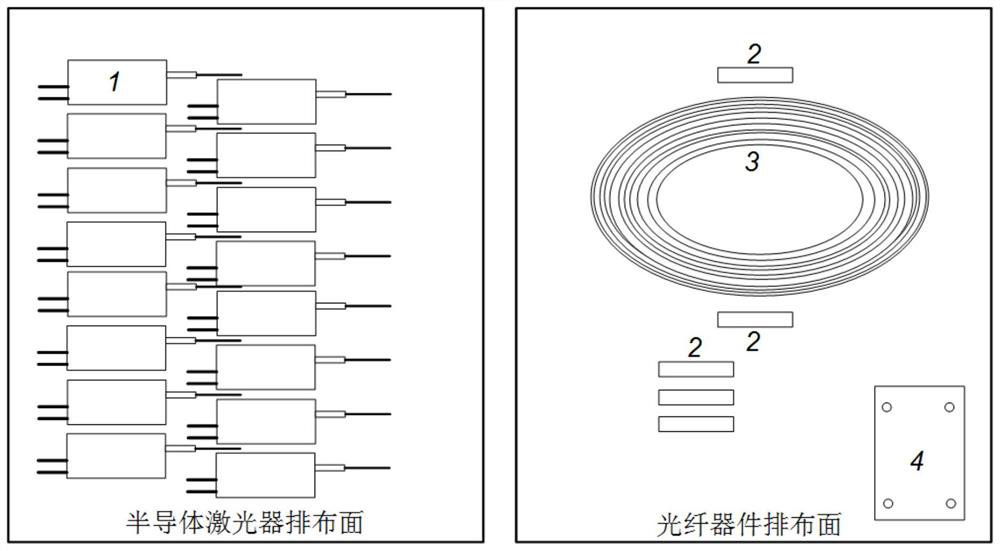

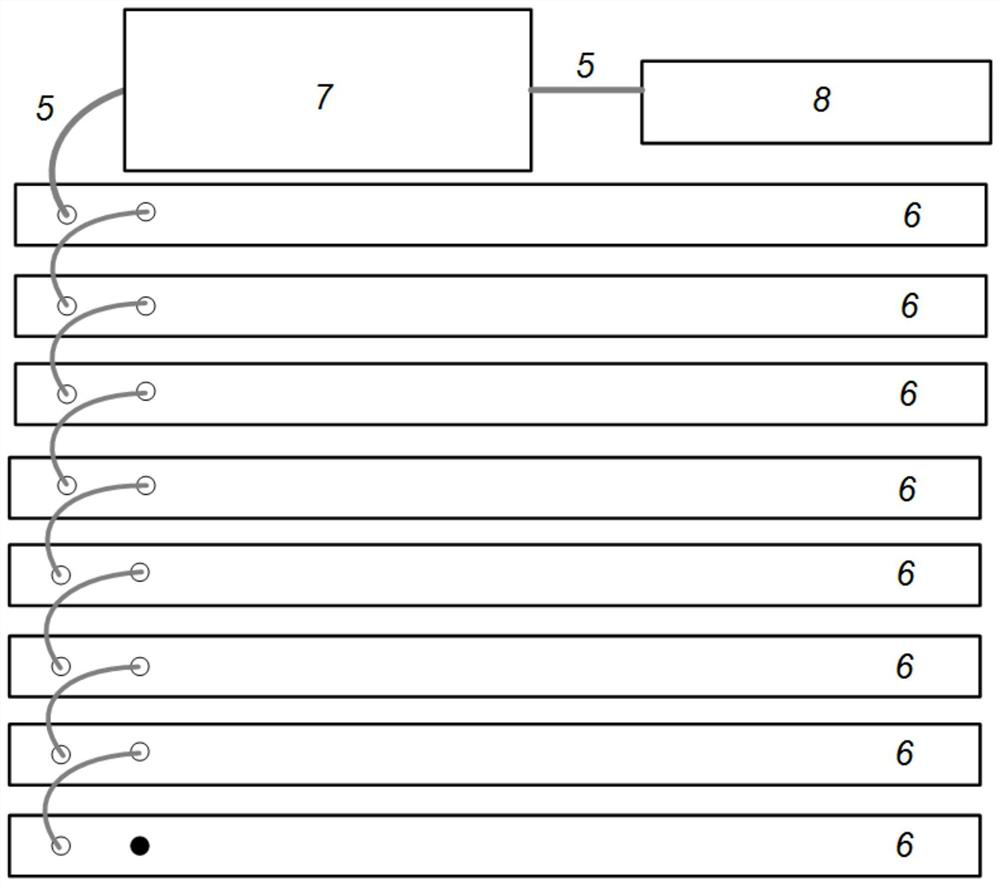

[0026] The embodiment of the invention discloses a fiber laser monitoring system, which includes a fiber laser and a sensor. Wherein, the sensor is a sensing optical fiber or a sensing optical cable, and the sensor uses Raman (Raman) scattering technology to perform continuous distributed real-time monitoring of the temperature parameters in the fiber laser.

[0027] Among them, the principle of using Raman (Raman) scattering effect for temperature measurement is: after the output laser light of high-power narrow-pulse laser pulsed semiconductor laser is incident on the sensing fiber, the laser interacts with the molecules in the fiber core to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com