Speckle suppression motion device based on diffractive optical element

A diffractive optical element and diffractive optical technology, applied in the field of adaptive motion devices, can solve the problems of poor laser speckle suppression effect, low transmission efficiency, low stability, etc., to achieve convenient upgrade and modification, low maintenance cost, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

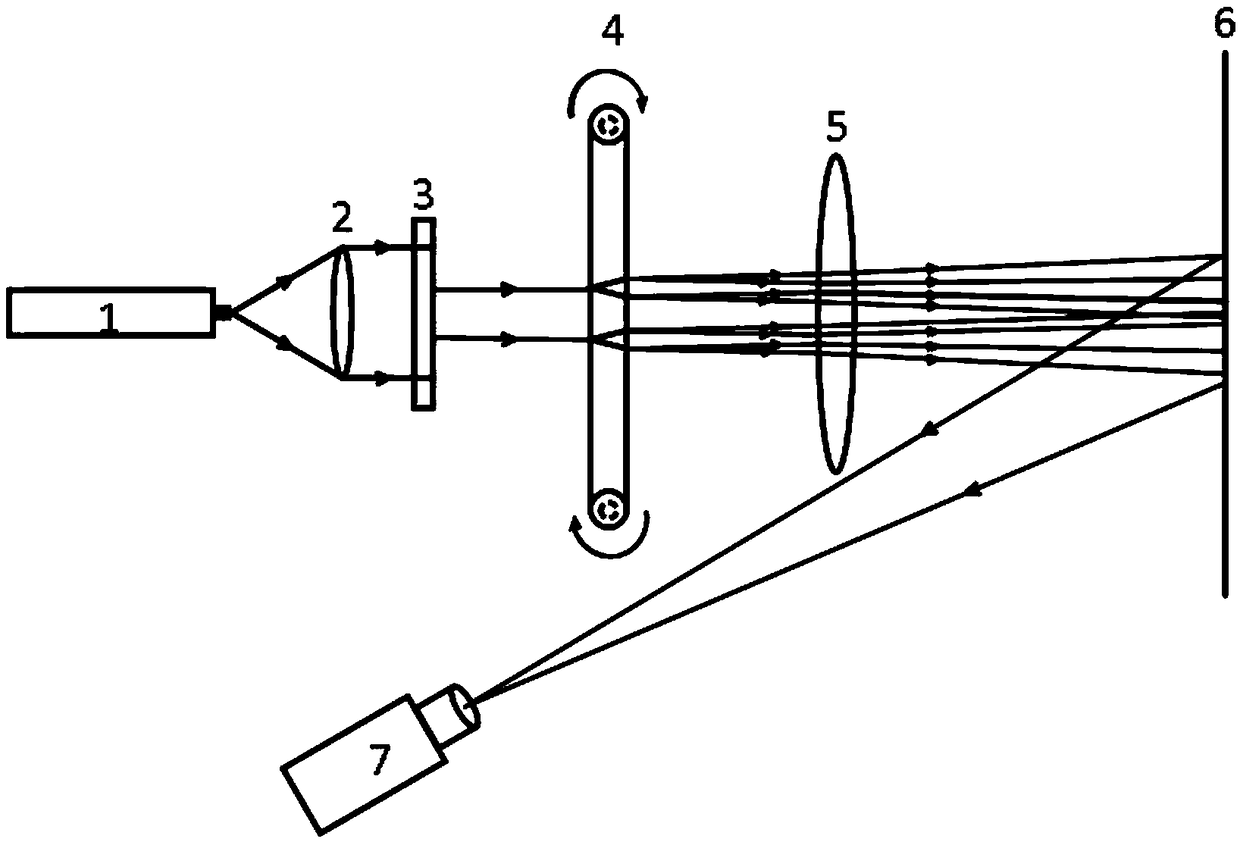

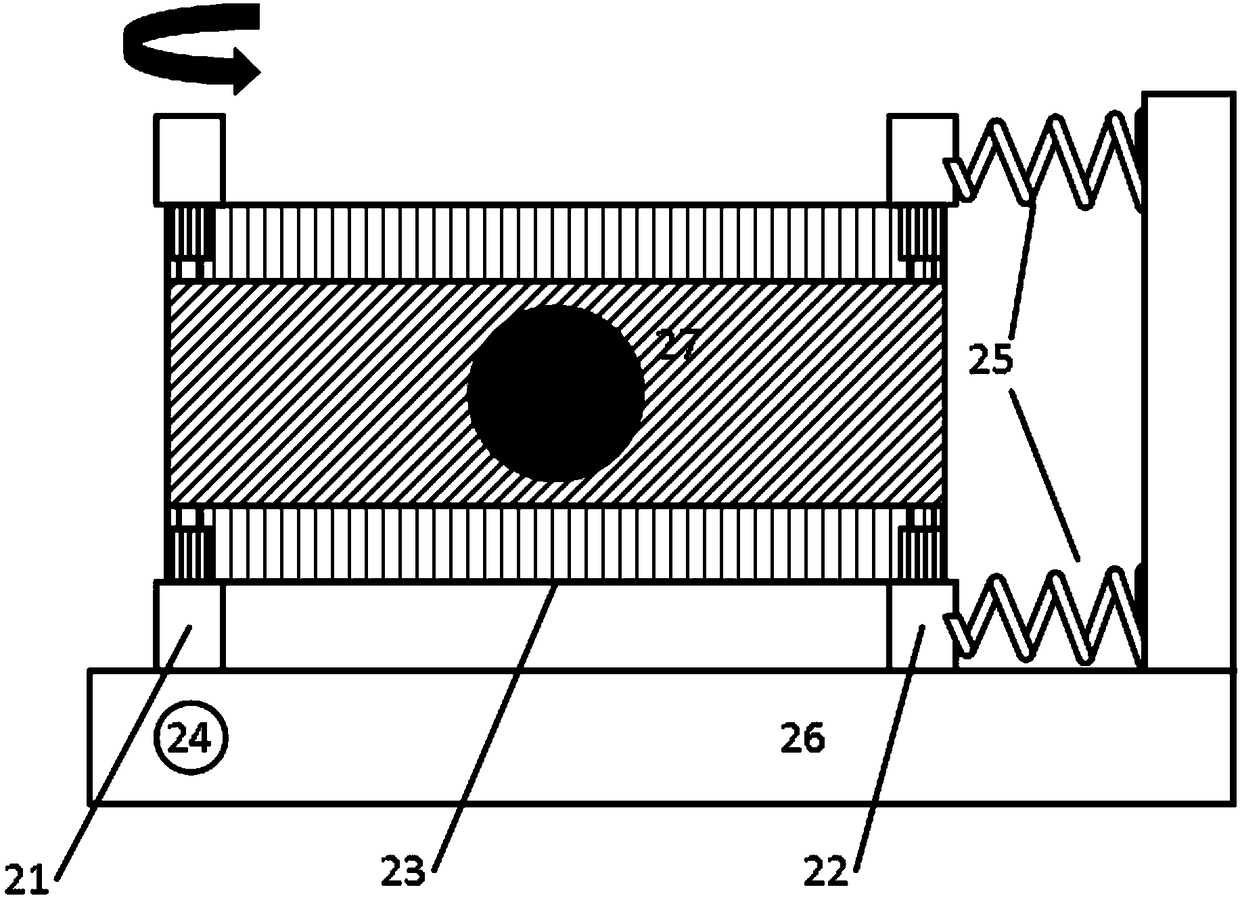

[0024] refer to Figure 1 to Figure 4 , a speckle suppression motion device based on a diffractive optical element, including a flexible film with a diffractive optical microstructure and a timing pulley column;

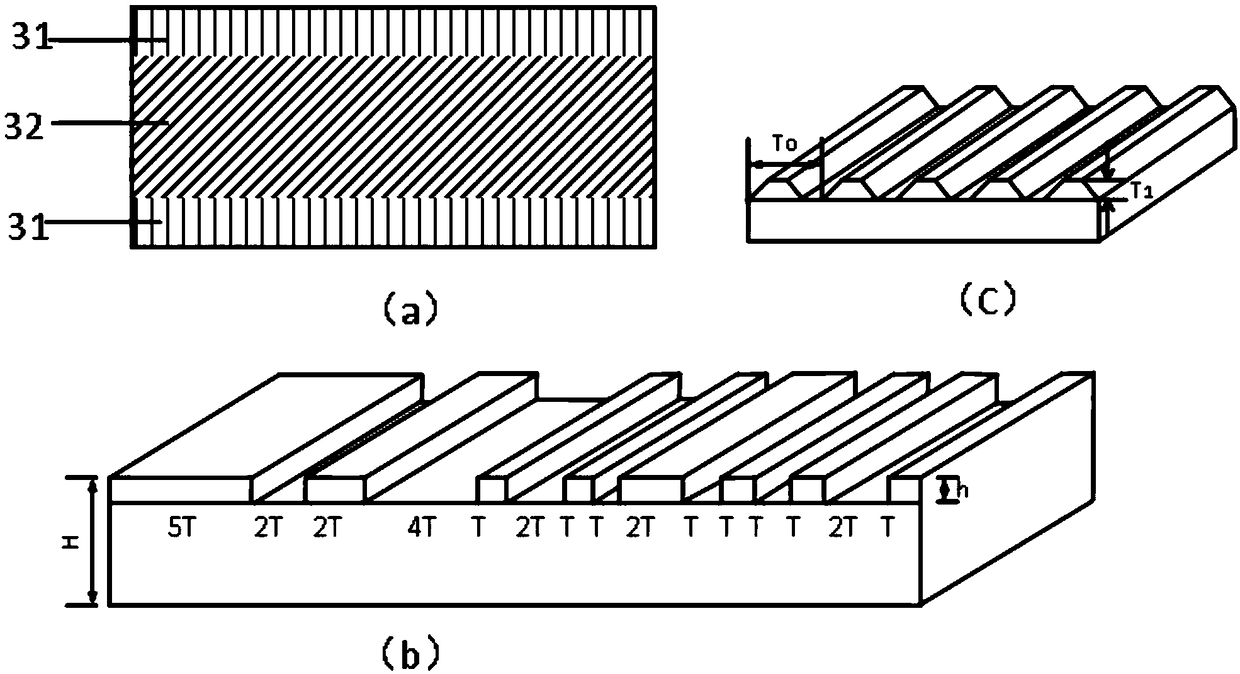

[0025] The flexible film with diffractive optical microstructure: the flexible film material is divided into upper, middle and lower sections. The middle transparent section is made of flexible variable-angle array diffractive optical microstructures to realize the laser speckle suppression function. The upper section and the lower section are single-sided synchronous belt structures with trapezoidal teeth or arc teeth, as a part of the transmission mechanism. The flexible film material is connected end-to-end in the inward direction of the synchronous belt structure, and is set on two synchronous belt columns driven by a motor to form a unidirectional circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com