A tooling structure for keyboard assembly

A keyboard and keycap technology, applied to electrical components, electric switches, circuits, etc., can solve problems such as keycap buckle deformation, whitening, and poor keycap installation, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

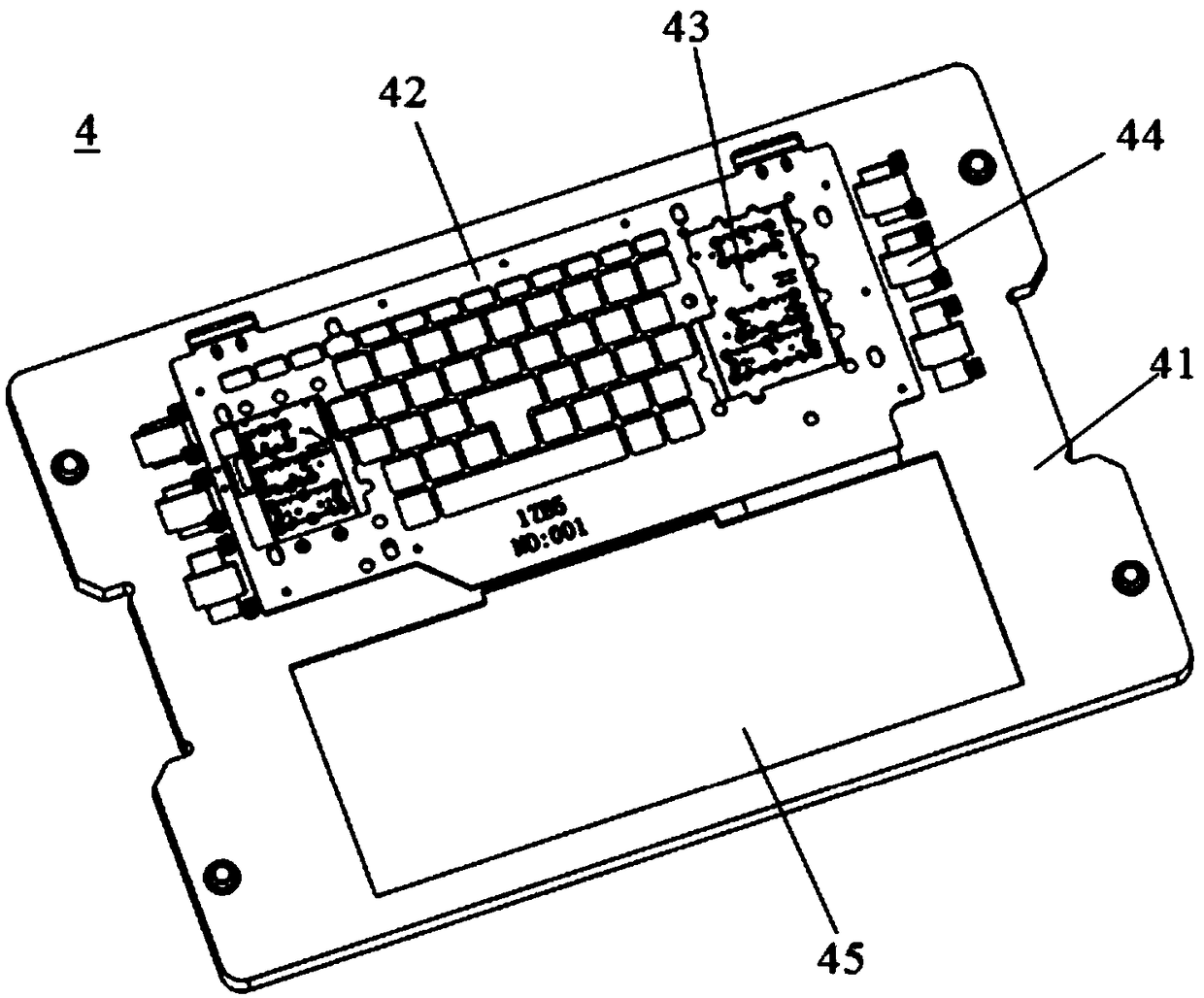

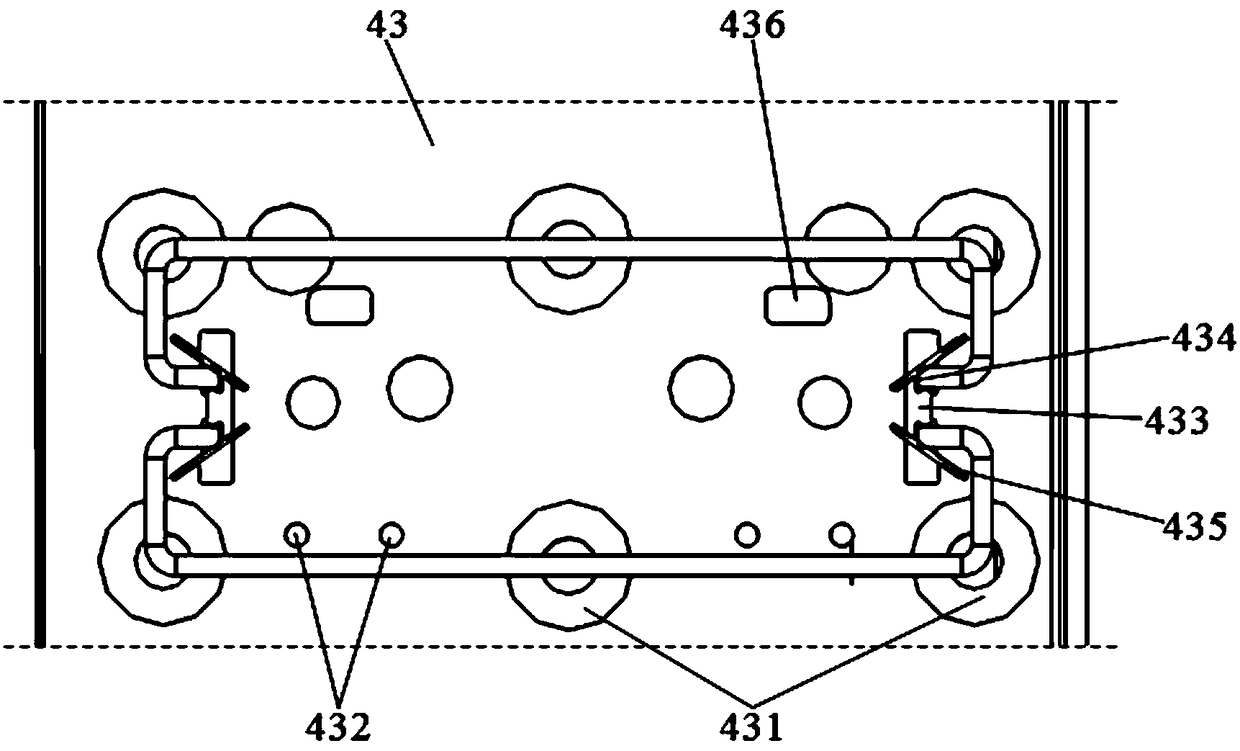

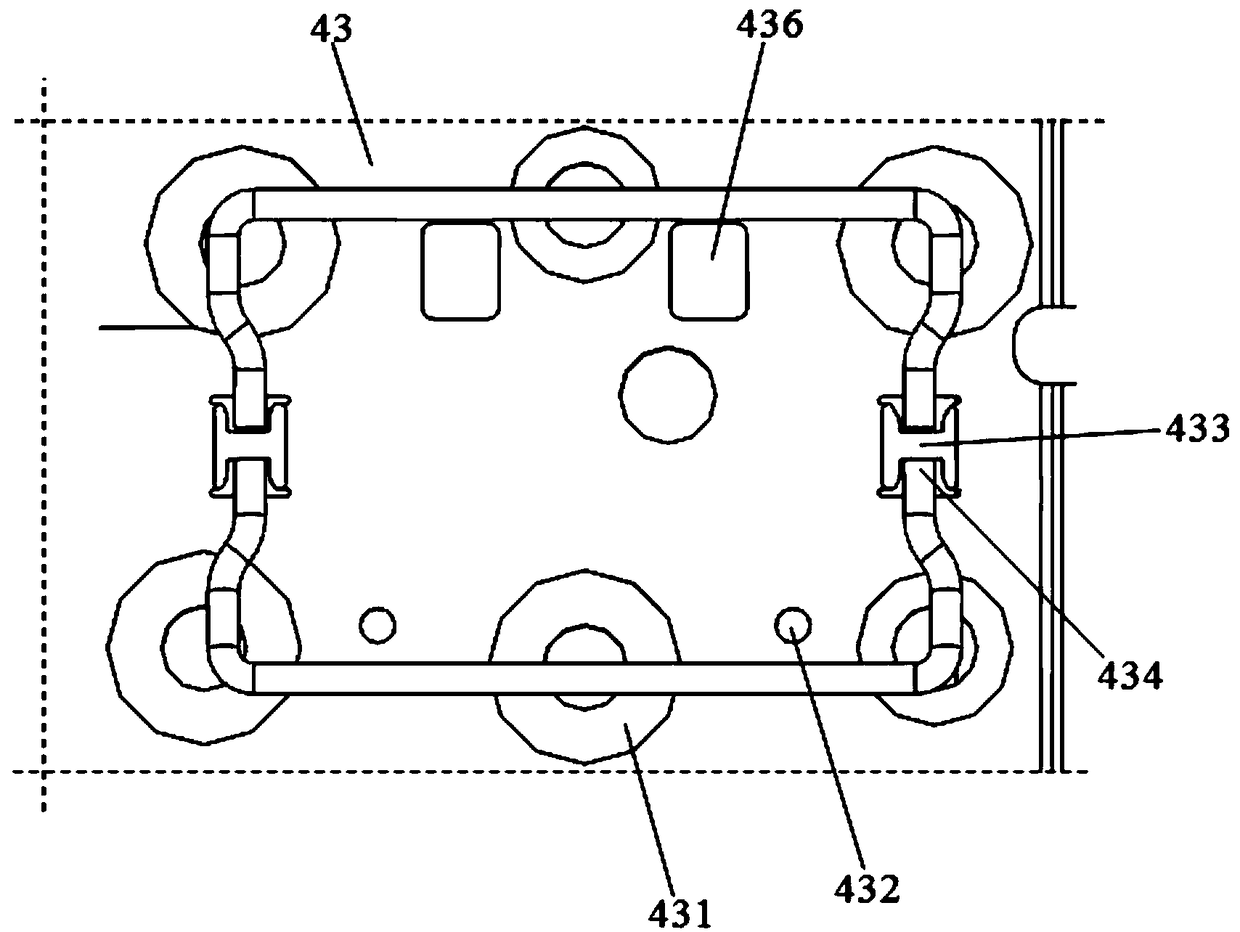

[0022] Please refer to Figure 1-Figure 3 , the present embodiment is a tooling structure 4 for keyboard assembly, which includes a bearing base plate 41 and a pressing plate 42 for flattening the base plate, and the base plate 41 is provided with a base plate receiving groove 43 . The substrate receiving groove 43 is provided with an installation auxiliary mechanism for limiting the installation of the balance bar and the keycap of the special function key. A magnetic block 431 , an elastic thimble 432 for pushing up the rotating shaft bracket in the base plate, a limiting block 433 for limiting the end of the balance bar, and a pressure supporting block 436 for supporting the rotating shaft bracket.

[0023] The limiting block 433 is provided with a limiting groove 434 that limits the depth of the end of the balance bar inserted into the mounting buckle of the substrate.

[0024] The first magnetic block 431 is arranged along the balance bar, which can ensure that the balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com