Automatic corrugated pipe cleaning device

A technology for cleaning devices and bellows, which is applied to heating devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as inability to clean and dry effects, and achieve cleaning and drying effects. The effect of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

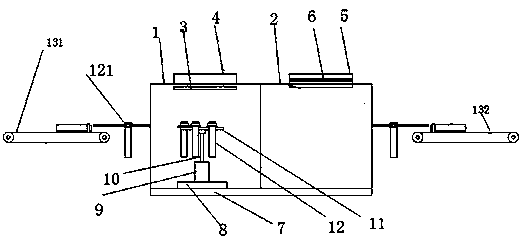

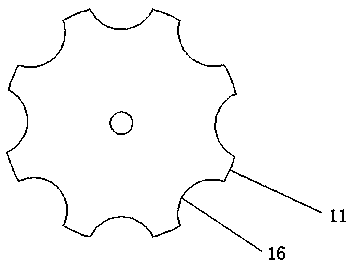

[0026] An automatic cleaning device for bellows, comprising a connected cleaning room and a drying room, the top of the cleaning room is provided with a spray head, the cleaning room and the drying room are separated by a pvc curtain, the spray head is connected to the water tank, and the water tank Filled with cleaning liquid; the top of the drying chamber is provided with an air outlet of the air duct, the air duct is connected to the fan, and the heating resistance wire is arranged in the air duct; the cleaning chamber and the bottom of the drying chamber are provided with two The track of the room is equipped with a slider on the track, and a motor is installed on the slider. The motor is an AKM series servo motor. The rotating rod of the motor is arranged vertically upwards. It is circular, and the end of the rotating rod is connected to the center of the hanging plate. There are multiple semicircular notches evenly distributed on the edge of the hanging plate. The opening...

Embodiment 2

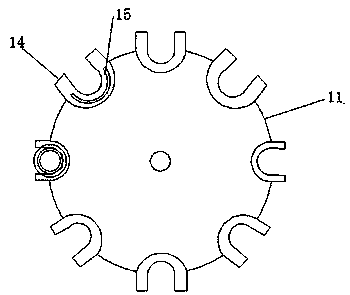

[0028] The top of the hanging plate is located at each notch and is provided with a U-shaped insert, the U-shaped insert covers the gap, the opening direction of the U-shaped insert is consistent with the opening direction of the notch, and the top of the U-shaped insert A semicircular protrusion is provided, a collar is sleeved on the end of the bellows, and an annular groove corresponding to the semicircular protrusion is provided on the contact surface of the collar and the U-shaped insert.

Embodiment 3

[0030] The bellows inlet is set on the side wall of the cleaning room, and the bellows outlet is opened on the side wall of the drying room. The bellows inlet is connected to the input conveyor belt, and the bellows outlet is connected to the output conveyor belt. Input transmission and output transmission A pair of mechanical arms (not visible in the figure) are respectively arranged on the belt. The mechanical arms are four-axis mechanical arms, which can move horizontally and vertically. There is an electromagnet at the end of the shaft; a horizontal bellows is placed on the input conveyor belt, and a collar is sleeved on the bellows. The collar is made of stainless steel. The mechanical arm above the input conveyor belt absorbs the collar through the electromagnet. Grab the corrugated pipe, and then rotate the horizontally placed corrugated pipe by 90° counterclockwise by operating the rotating shaft to vertically place it. Finally, the operating arm hooks the corrugated pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com