Substrate convey method and device

A technology for conveying devices and substrates, applied in the directions of spraying devices, spraying devices, cleaning methods and utensils, etc., to achieve the effect of improving cleaning and drying effects, and improving cleaning or drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

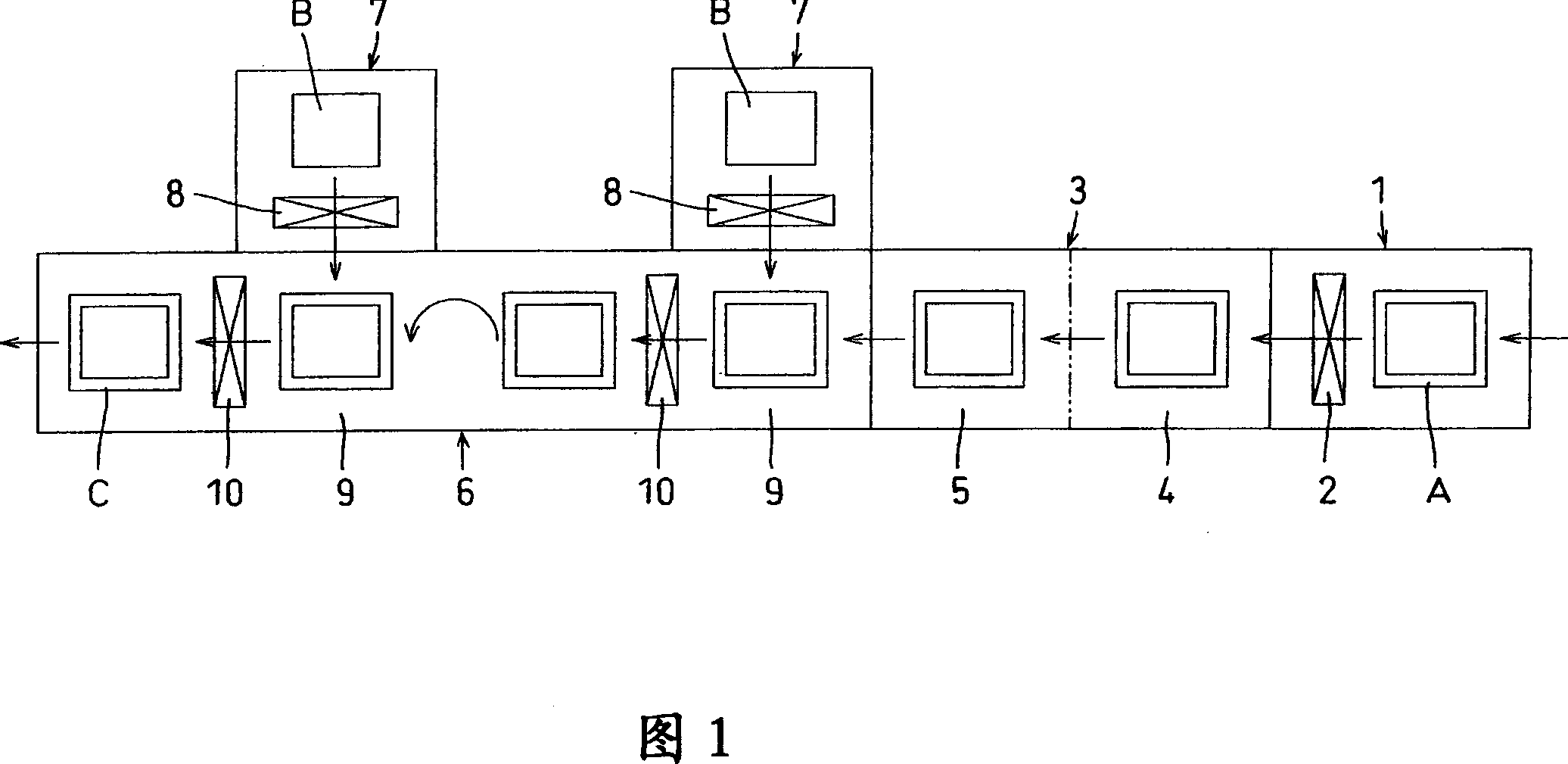

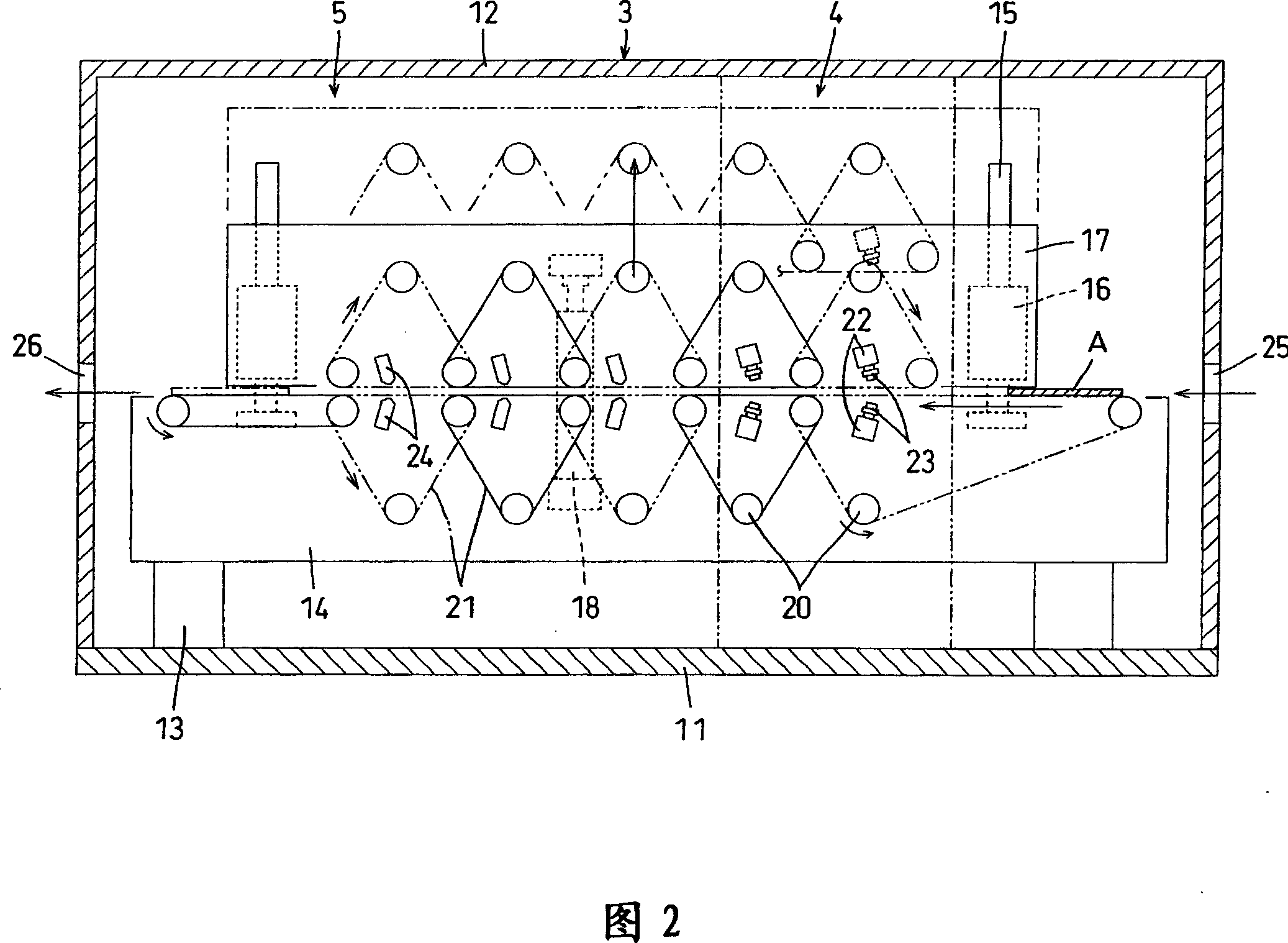

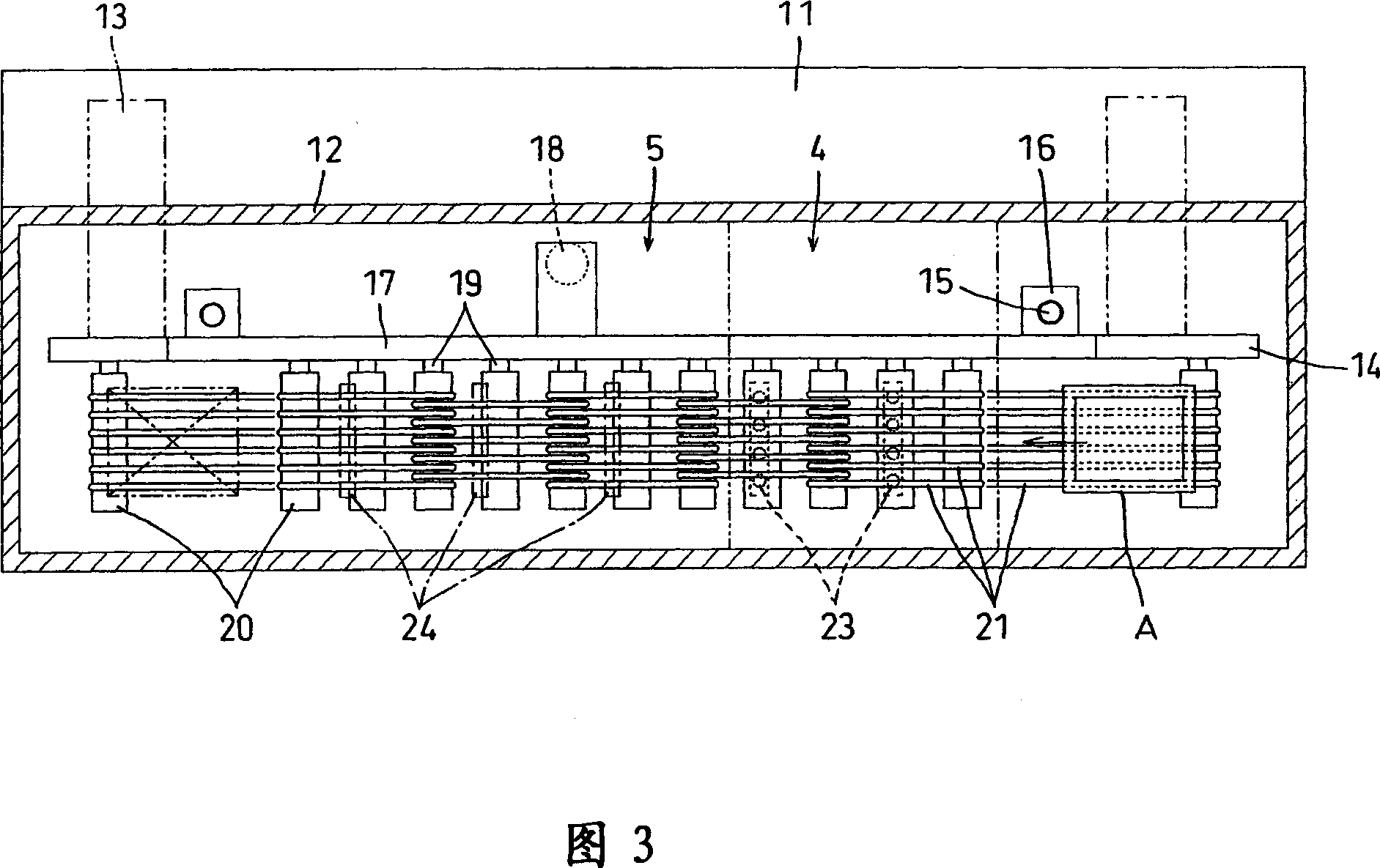

[0047] Fig. 1 is a plan view showing the entire polarizing plate sticking device of a liquid crystal glass substrate including a conveying device for a substrate of the present invention.

[0048] The liquid crystal glass substrate (hereinafter referred to as substrate A) is cut into a predetermined size in the previous step not shown, and sent to the cullet washer 1 to remove the glass debris (cullet) attached to the surface of the substrate A during cutting. ). In the sheet cleaning machine 2, the cullet adhering to the surface of the substrate A is peeled off by grinding the sheet or the like and cleaned, and then the cullet on the surface of the substrate A is completely removed through the washing area 4 and the drying area 5 in the cleaning device 3. After that, the substrate A is transferred to the polarizing plate sticking device 6, and the polarizing plate B is stuck on both sides of the substrate A, so that the liquid crystal panel C is produced.

[0049] As shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com