A fast corner positioning method in the process of free forging billet

A positioning method and forging technology, which is applied in the forging field of metallurgical systems, can solve problems such as increased grinding workload, easy folding of forgings, low production efficiency of forgings and low product quality, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

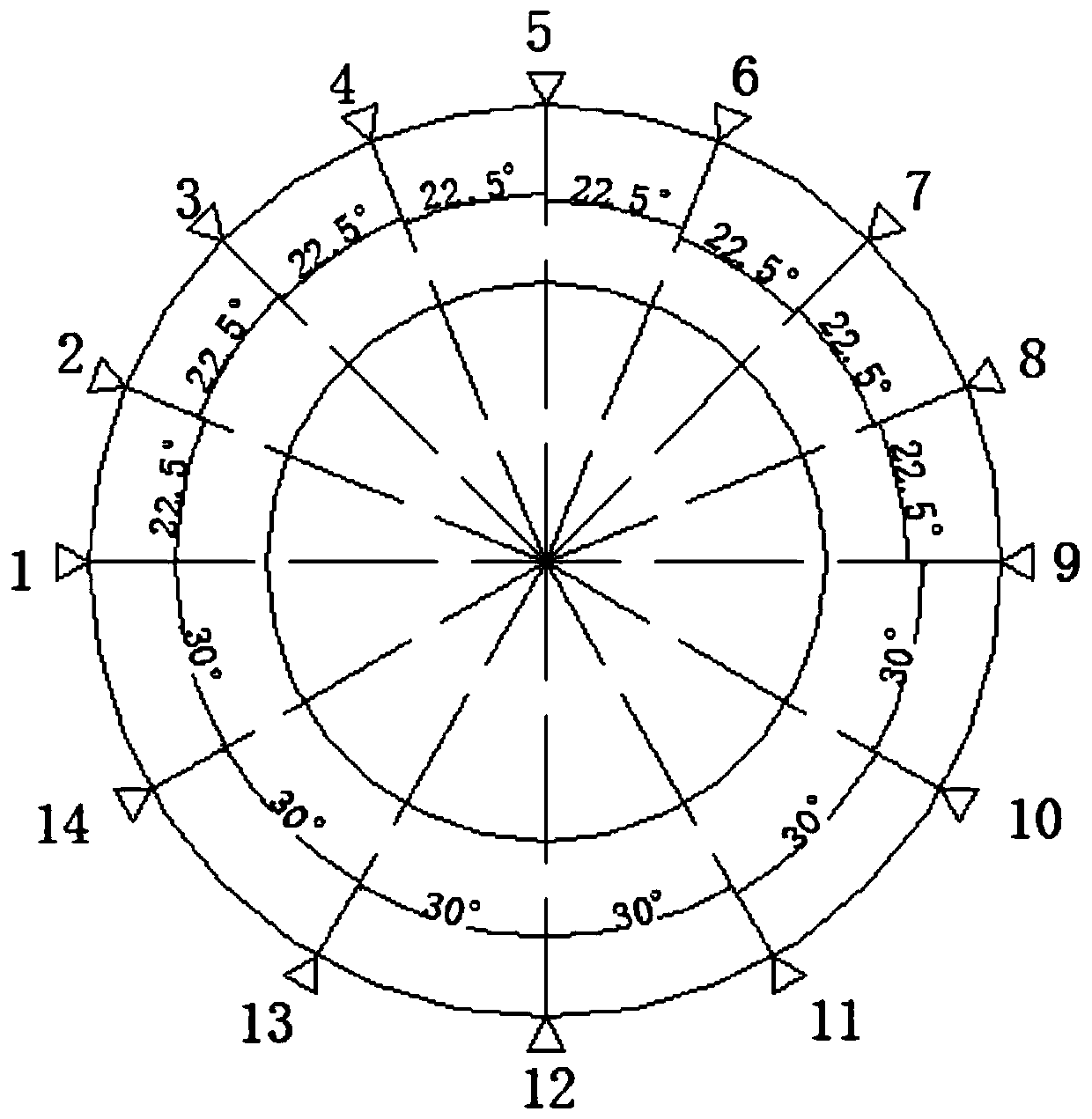

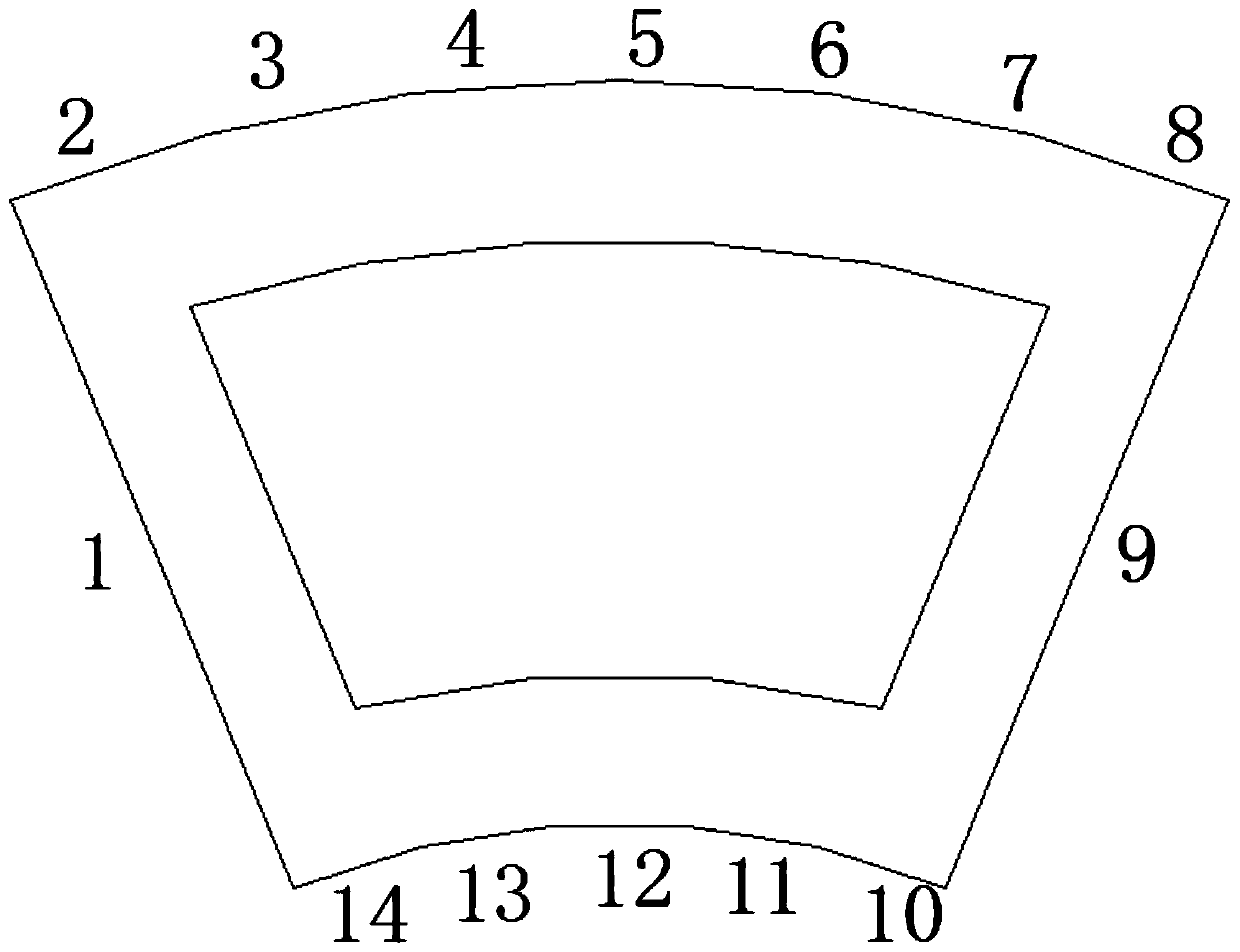

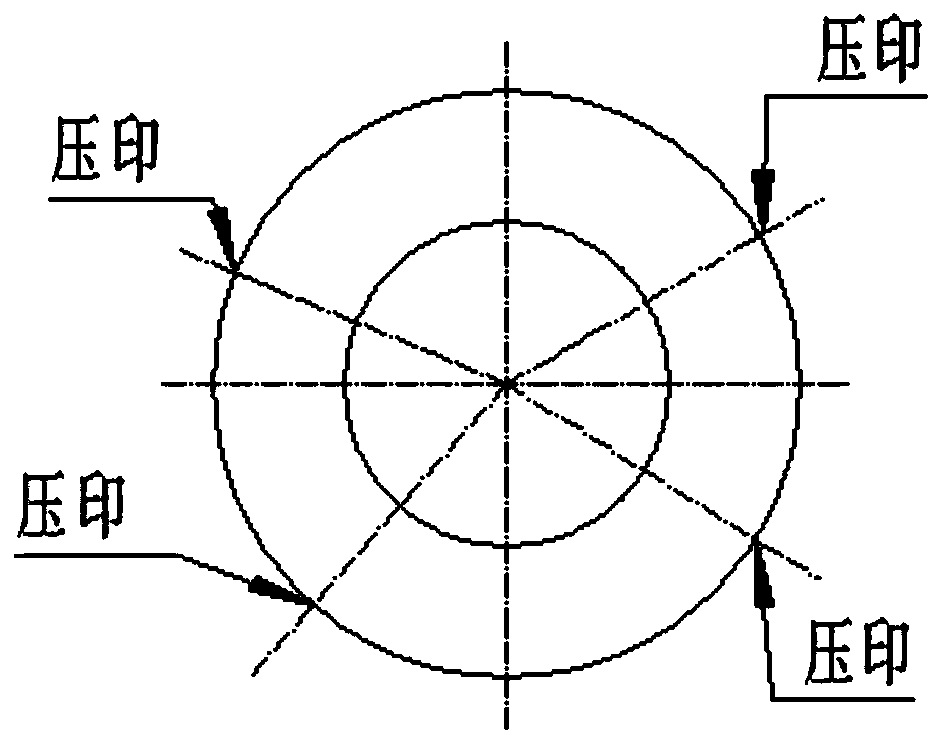

[0017] Such as Figure 1 to Figure 4 As shown, the present invention provides a method for quick positioning of corners in the free forging billet process, comprising the following steps:

[0018] Step 1. First place the ring-shaped blank after reaming vertically, and hammer once at the highest point of the blank along its radial direction;

[0019] Step 2. Roll the blank 22.5° along its outer circumference, and hammer once at the highest point of the blank along its radial direction;

[0020] Step 3, repeat step 2 a total of eight times;

[0021] Step 4. Roll the blank along its outer circumference for 30°, and hammer once at the highest point of the blank along its radial direction;

[0022] Step 5. Repeat step 4 for a total of five times.

[0023] The hammering force is the same for each hammering.

[0024] The method of the present invention requires 14 times of hammering on the periphery of the annular blank.

[0025] First place the ring-shaped blank that has been r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com