Method for preventing strip steel from being folded in coiling area

A folding method, technology of strip steel, applied in the field of steel rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

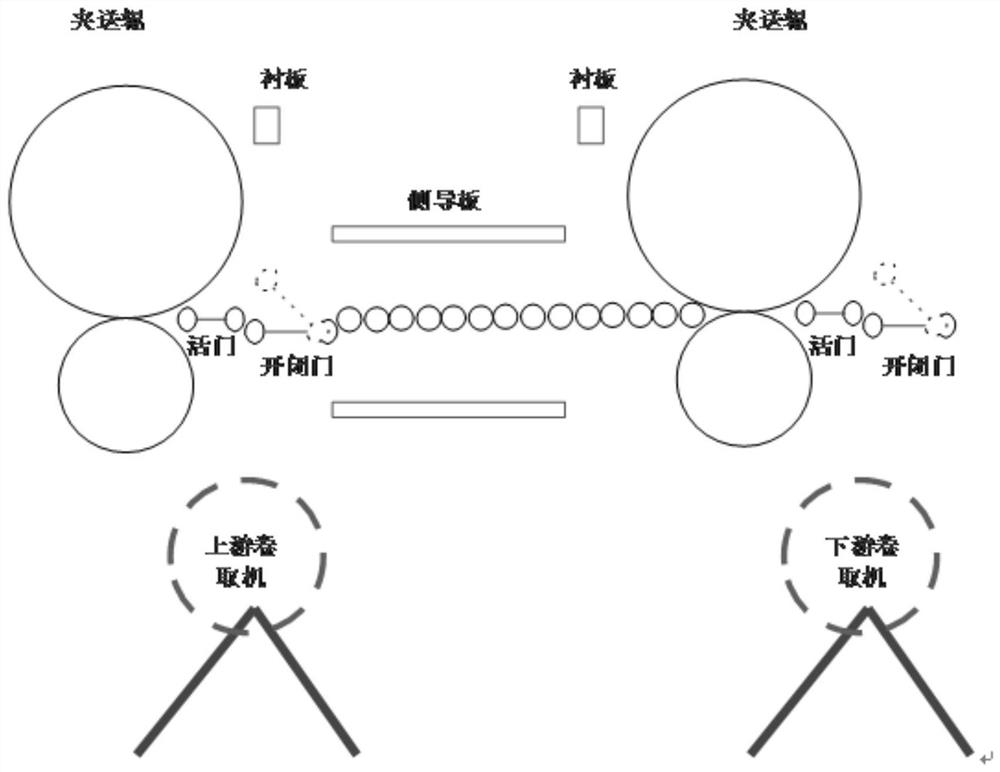

[0026] Example 1: see figure 1 , a method for preventing strip steel folding in a coiling region, said method comprising the steps of:

[0027] Step 1: Design and installation of equipment;

[0028] Step 2: On-site limit measurement data;

[0029] Step 3: Control program implementation.

[0030] Said step 1: design and installation of equipment, specifically as follows:

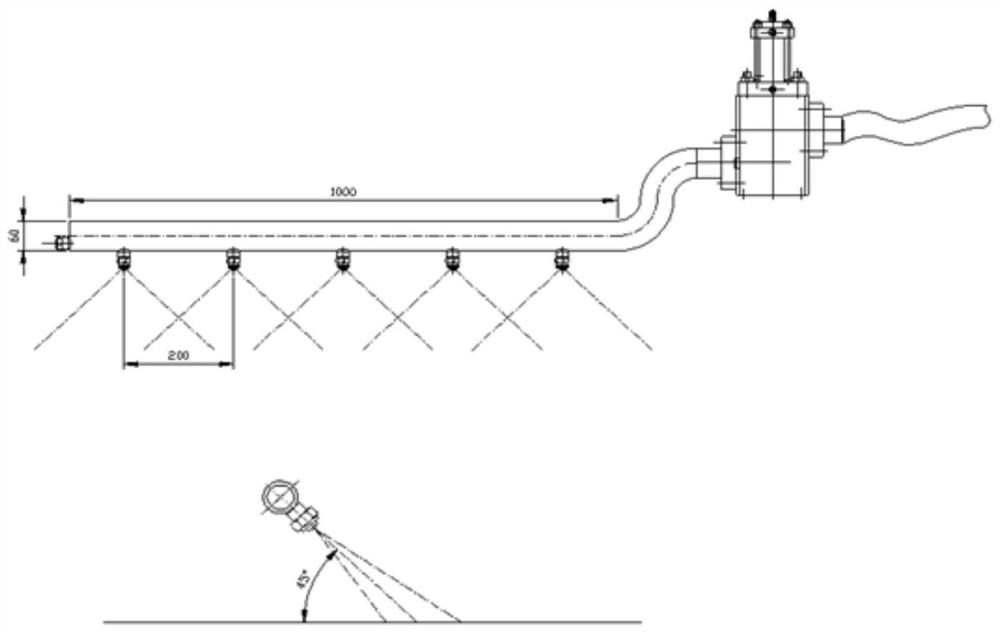

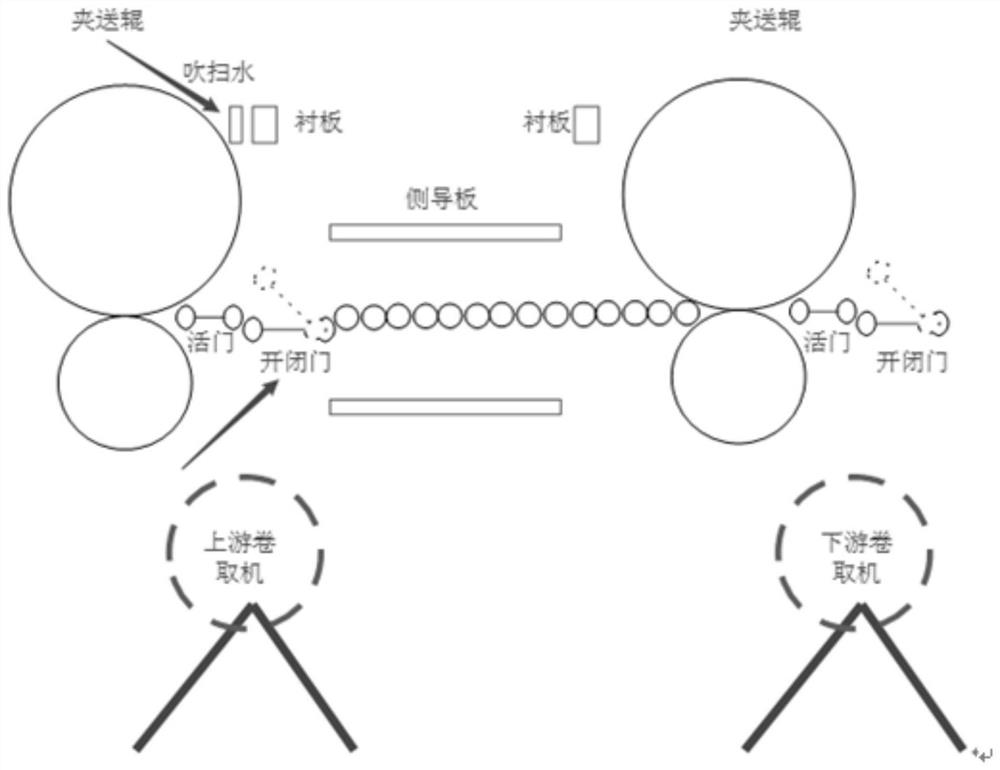

[0031] 1) Weld several nozzles equidistantly on the main header, the number is generally 3-8, as required, such as figure 2It is shown in the "Patented Equipment Design Drawing of the Invention". The nozzle design meets the following conditions: the blowing point of the blowing water must be above the output roller table, so as to avoid driving the strip head into the gap of the roller table. The direction of the middle nozzle coincides with the rolling center line, and the other nozzles are arranged in parallel at equal intervals to ensure uniform lateral force on the strip head. The spacing between e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com