Adjustable welding post base

A workstation seat and positioning plate technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenience for users, difficult to support positioning, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

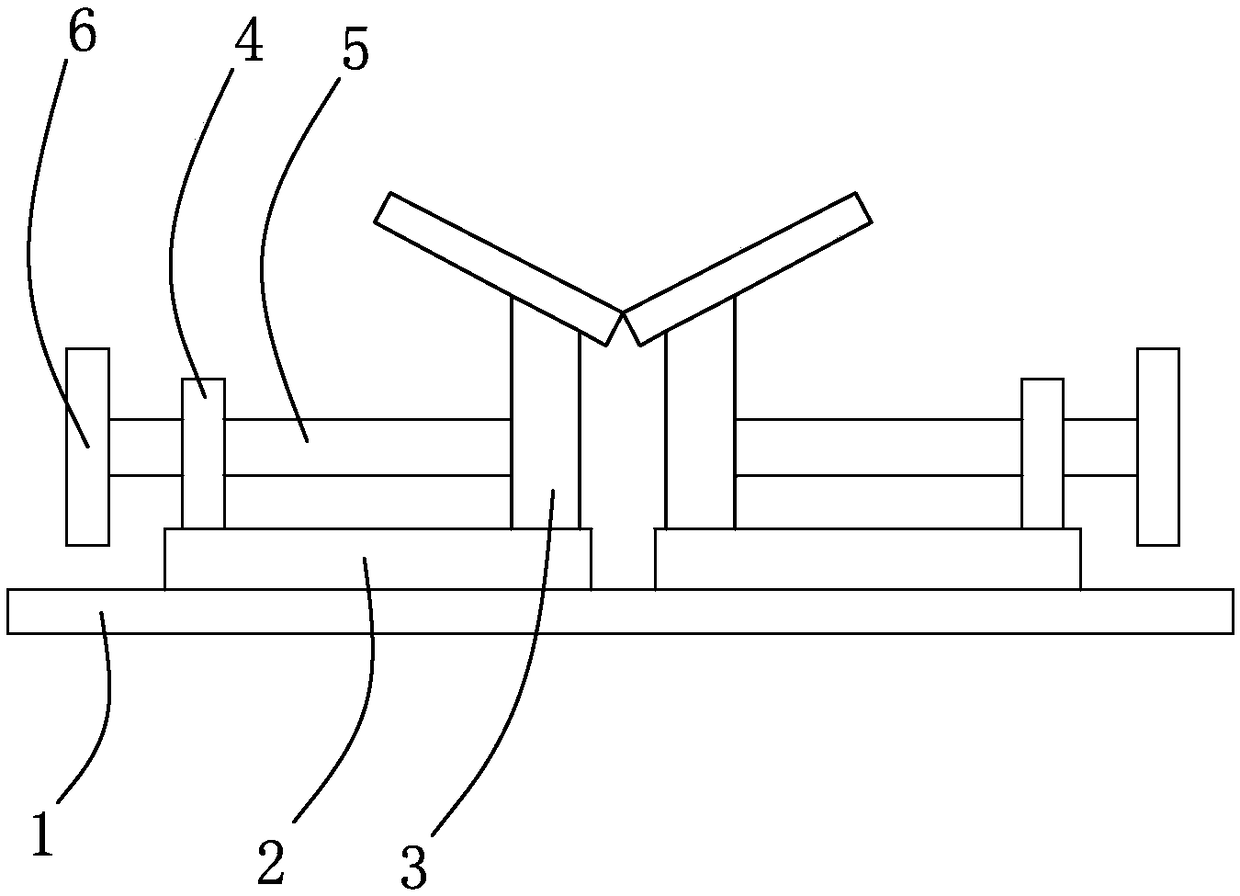

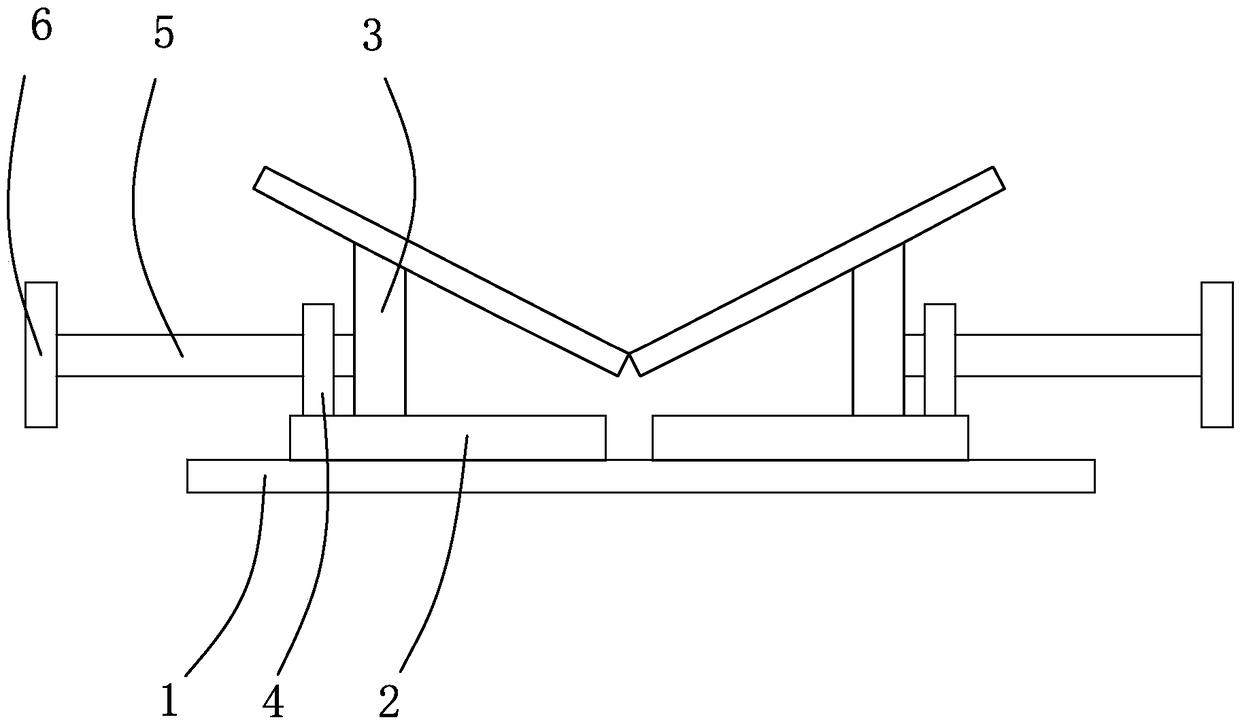

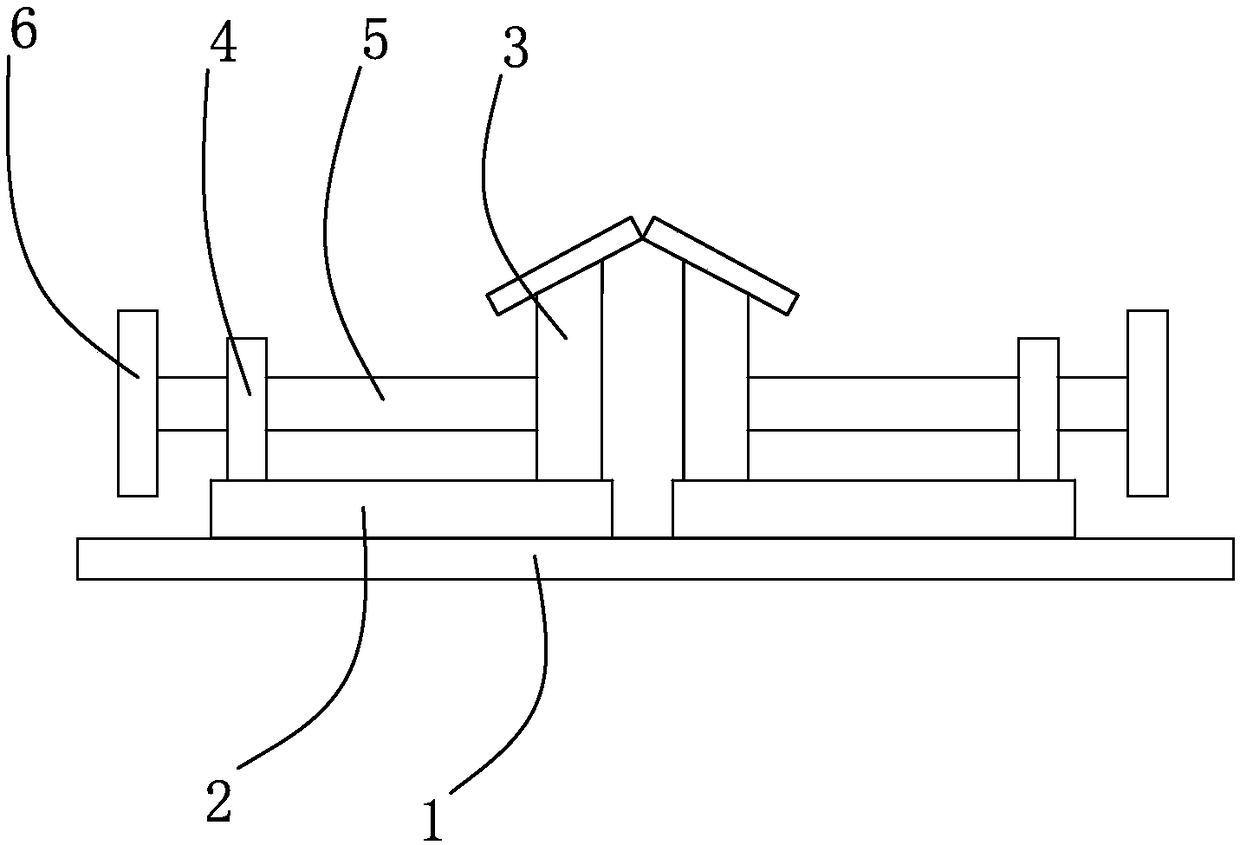

[0016] Such as Figure 1-Figure 4 As shown, an adjustable welding station seat provided by the present invention includes a frame 1, on which a slide rail 2 is symmetrically arranged, and a support block 3 is slidably provided on the two slide rails 2, and the support block 3 The upper end of the support block 3 is set as an inclined plane, and the support block 3 is driven by a power unit. Up and down towards the center of the two support blocks 3, the height gradually decreases, so that the slopes of the two support blocks 3 form a V-shaped support surface, which can place the workpiece welded on the inside of the joint between the two steel plates; the second type: the slope is set to From bottom to top close to the center of the two support blocks 3, the height gradually increases, so that the slopes of the two support blocks 3 form a triangular support surface, which can be placed to weld the workpiece outside the joint of the two steel plates.

[0017] In the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com