Graphene defrosting windshield wiper

A graphene, frost and rain technology, applied in the field of graphene defrosting wipers, can solve the problem of difficult removal of condensed frost on the front windshield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

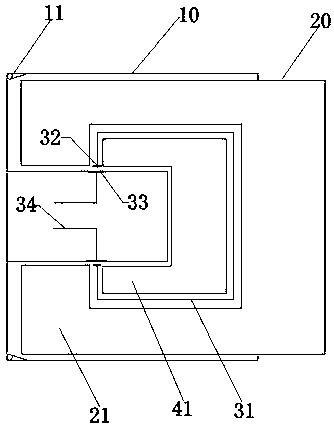

[0025] A graphene defrosting wiper, including a driving power supply, a swing arm and a wiper, the wiper includes a "giant" shaped scraper frame and a scraper core clamped in the scraper frame; the scraper core includes an inner Protective layer, graphene heating layer and soft scraping layer, the graphene heating layer includes a layer of graphene film, and the heating electrodes are respectively converged to two sets of conductive brush contacts through built-in circuits, that is, a set of positive electrode brush contacts and a set of negative electrodes Brush contacts; the inner protective layer is made of insulating material, filled between the graphene heating layer and the insulating convex stem inside the scraper frame; the soft scraper layer is wrapped outside the graphene heating layer; the scraper frame includes a bottom plate And the cuboid-shaped insulating stalk arranged along the longitudinal axis of the wiper on the inner side of the bottom plate, and the two si...

Embodiment 2

[0027]A graphene defrosting wiper, including a driving power supply, a swing arm and a wiper, the wiper includes a "giant" shaped scraper frame and a scraper core clamped in the scraper frame; the scraper core includes an inner Protective layer, graphene heating layer and soft scraping layer, the graphene heating layer includes 2 layers of graphene film, the heating power is divided into 2 levels, and the heating electrodes are respectively converged to two sets of conductive brush contacts through the built-in circuit, that is, a set of positive electrodes Brush contacts and a set of negative electrode brush contacts; the inner protective layer is made of insulating material, filled between the graphene heating layer and the insulating convex stem inside the scraper frame; the soft scraping layer is wrapped outside the graphene heating layer The scraper frame includes a bottom plate and a cuboid-shaped insulating stalk arranged on the inner side of the bottom plate along the l...

Embodiment 3

[0029] A graphene defrosting wiper, including a driving power supply, a swing arm and a wiper, the wiper includes a "giant" shaped scraper frame and a scraper core clamped in the scraper frame; the scraper core includes an inner Protective layer, graphene heating layer and soft scraping layer, the graphene heating layer includes 2 layers of graphene film, the heating power is divided into 2 levels, and the heating electrodes are respectively converged to two sets of conductive brush contacts through the built-in circuit, that is, a set of positive electrodes Brush contacts and a set of negative electrode brush contacts; the inner protective layer is made of insulating material, filled between the graphene heating layer and the insulating convex stem inside the scraper frame; the soft scraping layer is wrapped outside the graphene heating layer The scraper frame includes a bottom plate and a cuboid-shaped insulating stalk arranged on the inner side of the bottom plate along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com