Defrosting device for vehicle glass

A technology of automobile glass and spraying device, which is applied in the field of automobile manufacturing, can solve the problems such as difficult removal of frost and achieve the effect of reducing heat loss and improving heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

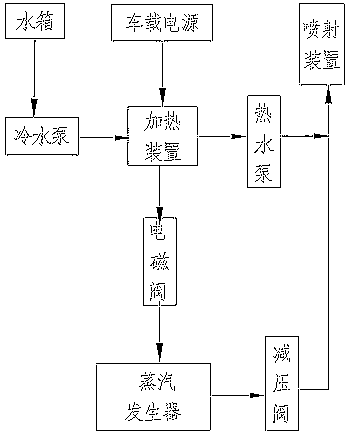

[0016] A car glass defrosting device, including a vehicle-mounted power supply, a water tank, a cold water pump, a heating device, a hot water pump, a solenoid valve, a steam generator, a pressure reducing valve, a spray device and a control table, the vehicle-mounted power supply provides power for the entire defrosting device, The control panel controls the defrosting device through the integrated circuit system; after the water pumped from the water tank by the cold water pump enters the heating device to be heated, it is pressurized by the hot water pump and sprayed out from the injection device, and is used in conjunction with the wiper to melt the frost on the car glass; or from The hot water heated by the heating device enters the steam generator through the electromagnetic valve to generate water vapor, and the water vapor is sprayed from the injection device to the automobile glass through the pressure reducing valve, and the wiper is used together to melt the frost on ...

Embodiment 2

[0018] A car glass defrosting device, including a vehicle-mounted power supply, a water tank, a cold water pump, a heating device, a heat-preserving hot water tank, a hot water pump, a solenoid valve, a steam generator, a heat-retaining steam tank, a decompression valve, a spray device and a control table, and the vehicle-mounted The power supply provides power for the entire defrosting device, and the control panel controls the defrosting device through the integrated circuit system; the water pumped from the water tank by the cold water pump enters the heating device to be heated and temporarily stored in the heat-insulating hot water tank, and then the water pumped from the heat-insulating hot water The tank is pumped out and pressurized and sprayed out from the injection device, and the wiper is used together to melt the frost on the car glass; or the hot water heated from the heating device enters the steam generator through the solenoid valve to generate water vapor and te...

Embodiment 3

[0020] A defrosting device for automobile glass, comprising a vehicle-mounted power supply, a water tank, a cold water pump, a heating device, a hot water pump, a solenoid valve, a steam generator, a pressure reducing valve, a spray device and a control table, and the vehicle-mounted power supply provides power for the entire defrosting device; After the water pumped from the water tank by the cold water pump enters the heating device to be heated, it is pressurized by the hot water pump and sprayed out from the injection device, and is used in conjunction with the wiper to melt the frost on the car glass; or the hot water heated by the heating device enters the steam through the solenoid valve The generator generates water vapor, and the water vapor is sprayed from the injection device to the automobile glass through the pressure reducing valve, and the wiper is used together to melt the frost on the automobile glass; the injection outlet of the injection device is set on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com