High-efficiency heavy slag separator

A heavy-duty and high-efficiency technology, used in textiles and papermaking, fiber raw material processing, etc., can solve the problems affecting the quality of wood pulp, dust and impurities, and achieve good slag removal, improve wood pulp quality, and remove dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

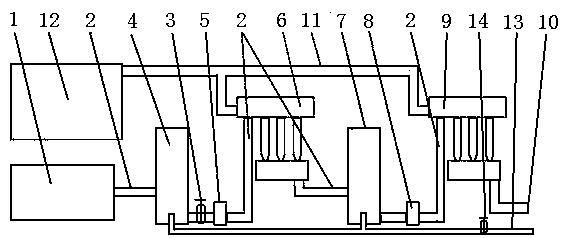

[0010] Such as figure 1 As shown, a high-efficiency heavy slag remover is characterized by a pressure screen 1, a wood pulp delivery pipe 2, a wood pulp hand valve 3, a No. 1 standpipe 4, a No. 1 delivery pump 5, and a No. 1 slag remover 6 , No. 2 standpipe 7, No. 2 delivery pump 8, No. 2 slag remover 9, outlet 10, good pulp delivery pipe 11, unrefined slurry tank 12, clean water delivery pipe 13, and clean water hand valve 14. Wood pulp conveying pipe 2 and good pulp conveying pipe 11 are made of 0.02 cm thick steel plate with a diameter of 20 cm; No. 1 standpipe 4 and No. 2 standpipe 7 are made of 0.05 cm thick steel plate with a diameter of 50 cm; clear water conveying pipe 13 Made of steel plate with a thickness of 0.02 cm and a diameter of 10 cm; the pressure screen 1 is connected to the No. 1 standpipe 4, the wood pulp hand valve 3, the No....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com