Beam-column joint for fabricated concrete frame structure

A frame structure, beam-column joint technology, applied in the direction of building structure, construction, etc., can solve the problems of unable to meet the performance requirements of joint connection stably, difficult to achieve precise construction, and slow down the construction progress, etc., to achieve simple and feasible design, The effect of reliable design and simplified connection form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

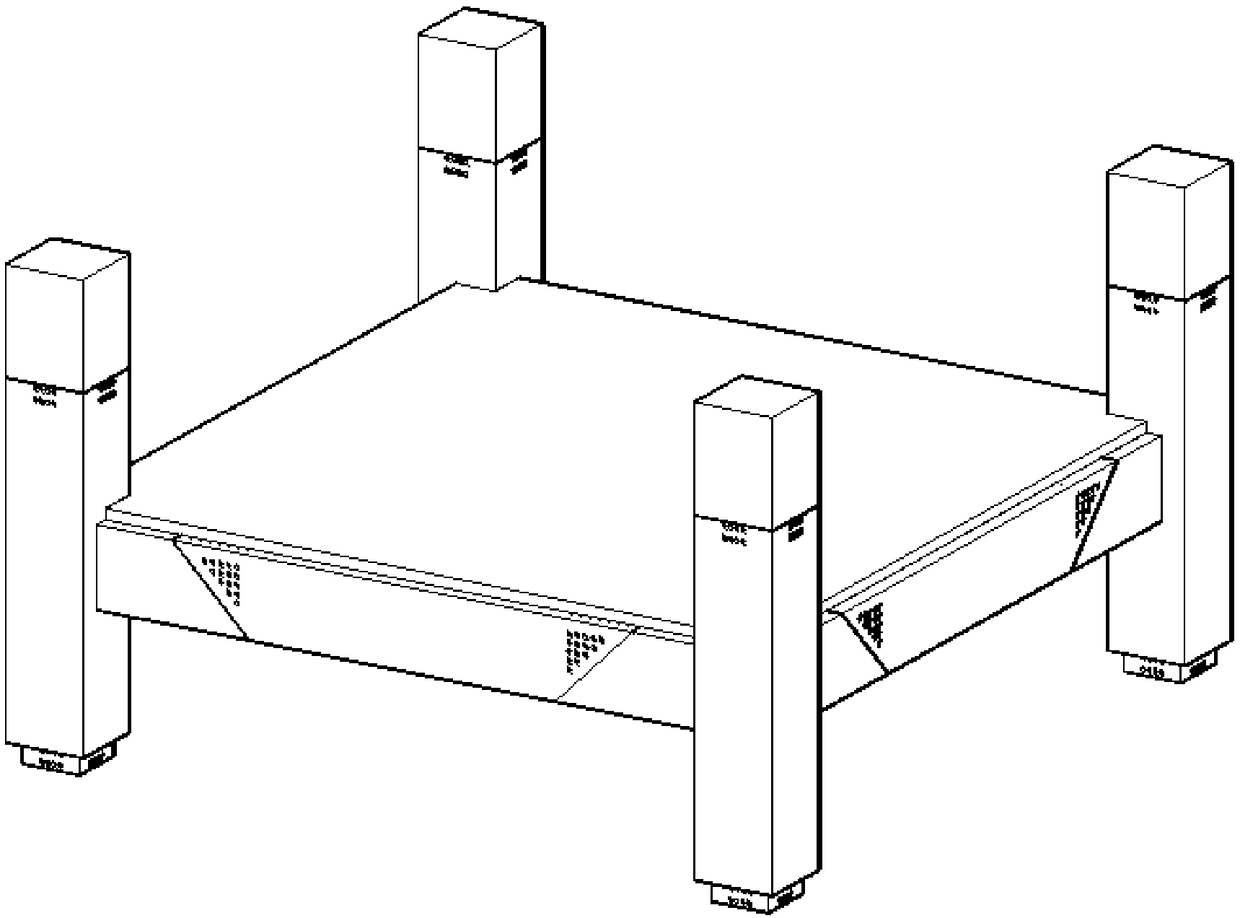

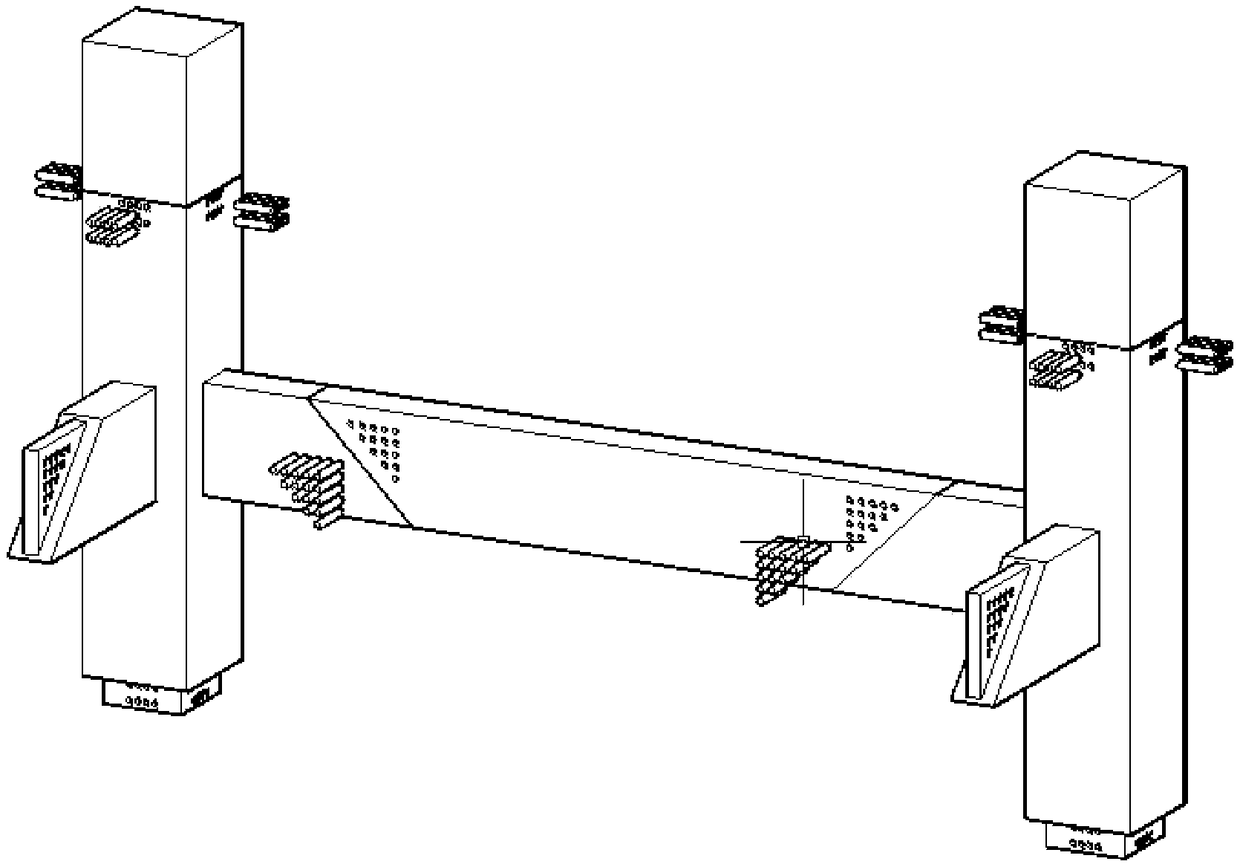

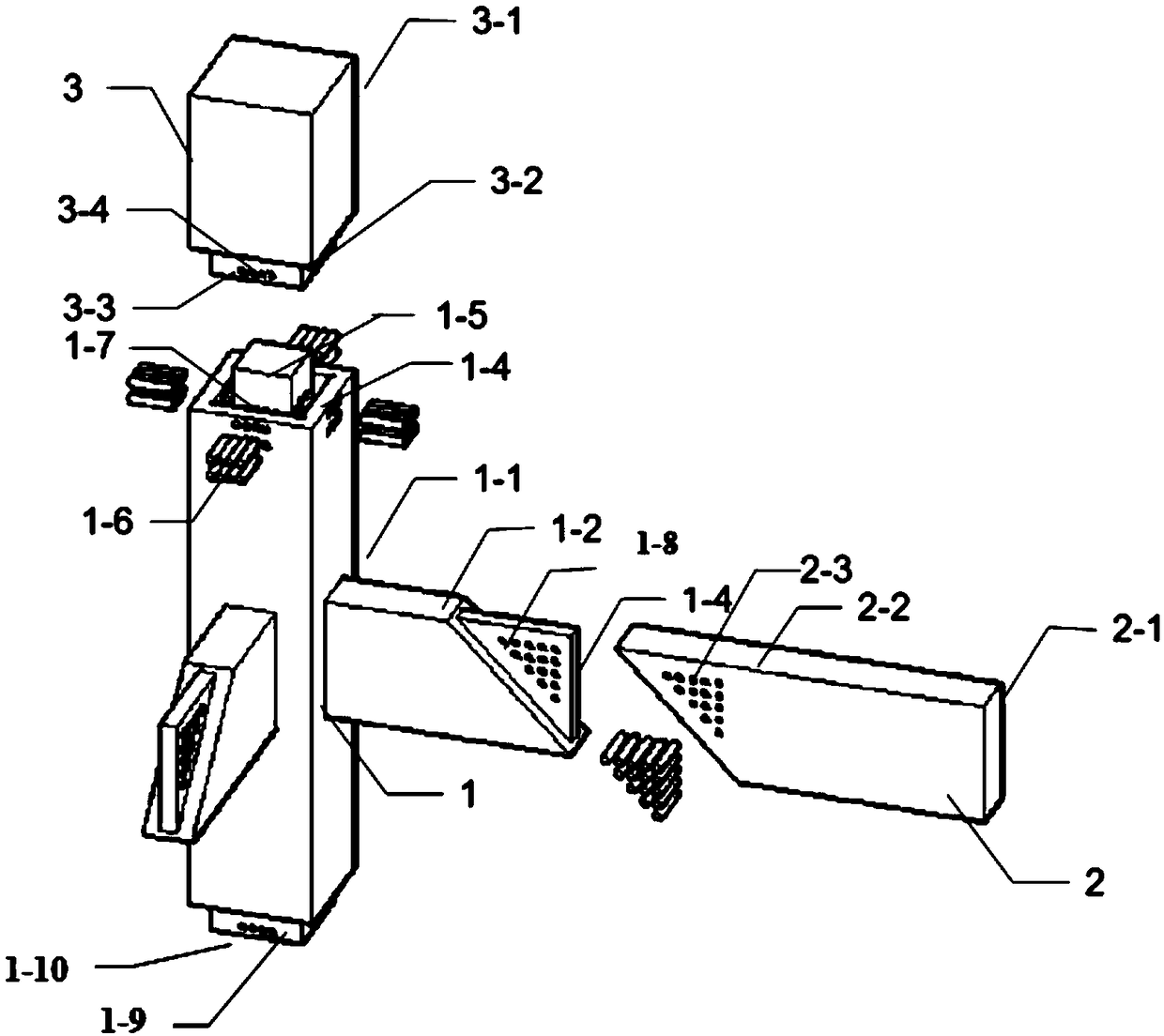

[0036] Such as Figures 1 to 3 As shown, a beam-column node for a prefabricated concrete frame structure includes a node unit 1, a beam unit 2, and a column unit 3. The node unit 1 includes a rectangular concrete column 1-1, which extends along the horizontal direction and is vertically arranged on At least two beam connecting sections 1-2 in the middle of the concrete column 1-1, the upper and lower ends of the concrete column 1-1 and the column unit 3 are provided with matching quick plug-in components and fastened by high-strength bolts; The connection between the beam connection section 1-2 and the beam unit 2 is provided with a matching quick plug assembly and fastened by high-strength bolts, and the connection position between the beam connection section 1-2 and the beam unit 2 is located at 1 / 4 of the middle.

[0037] The size of the concrete column 1-1 is 750*750*3250mm, and its upper end is centered with a first "back"-shaped depression 1-4, and the center of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com