Axis runout trajectory test device

A testing device and beating technology, which is applied to cutters, agricultural machinery and tools, and applications, can solve problems such as device damage, friction and collision, and continuous beating of the axis, so as to avoid axis misalignment, simple structure, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The axis beating track test device of the present invention can be used for the beating track test of various rotating shafts. The following uses the axis beating track test device for Taihu Star TH988 combine harvester axis beating track test as an example, combined with The accompanying drawings illustrate the present invention in further detail, but the protection scope of the present invention is not limited thereto.

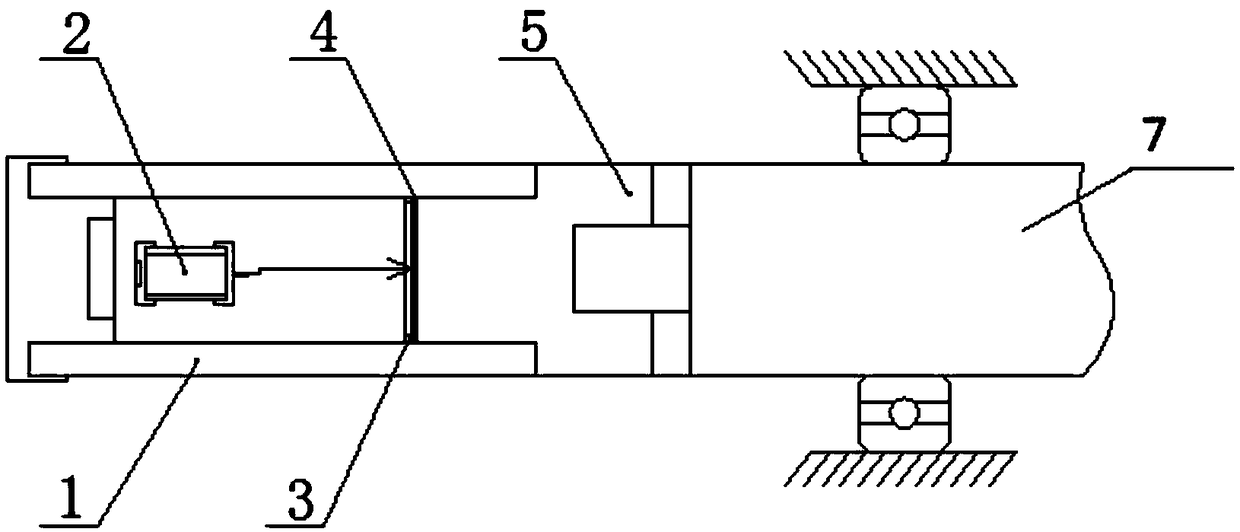

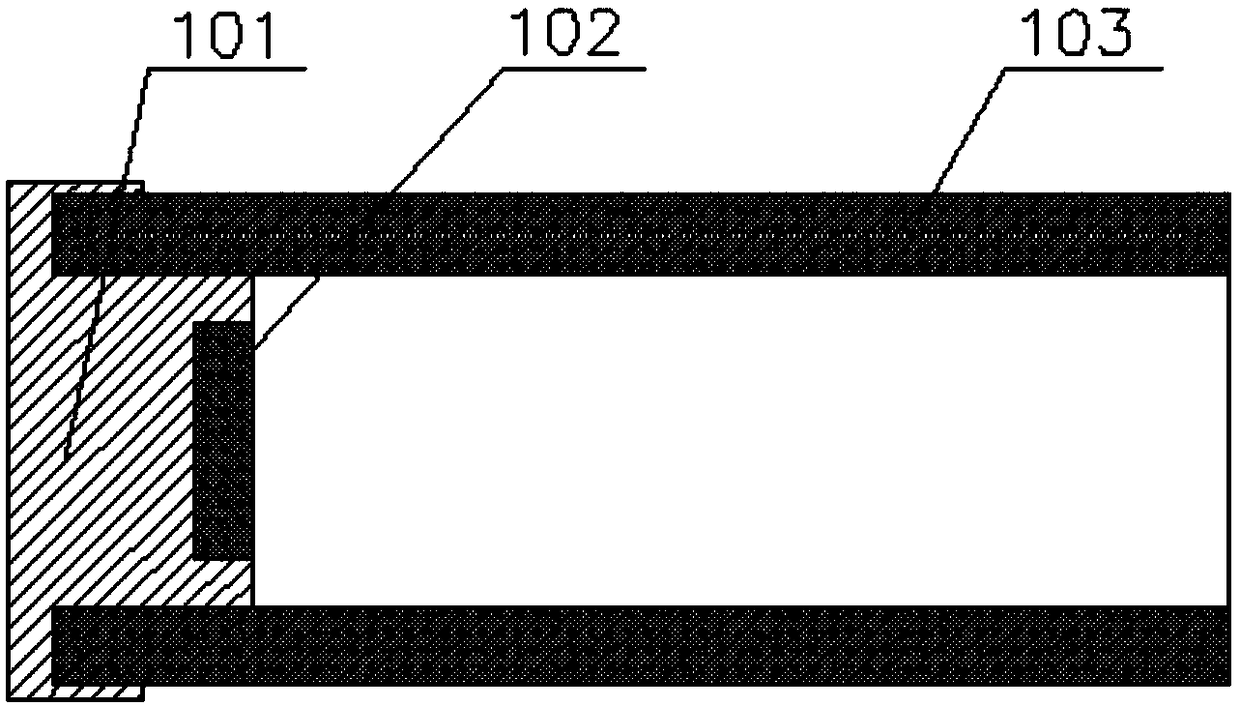

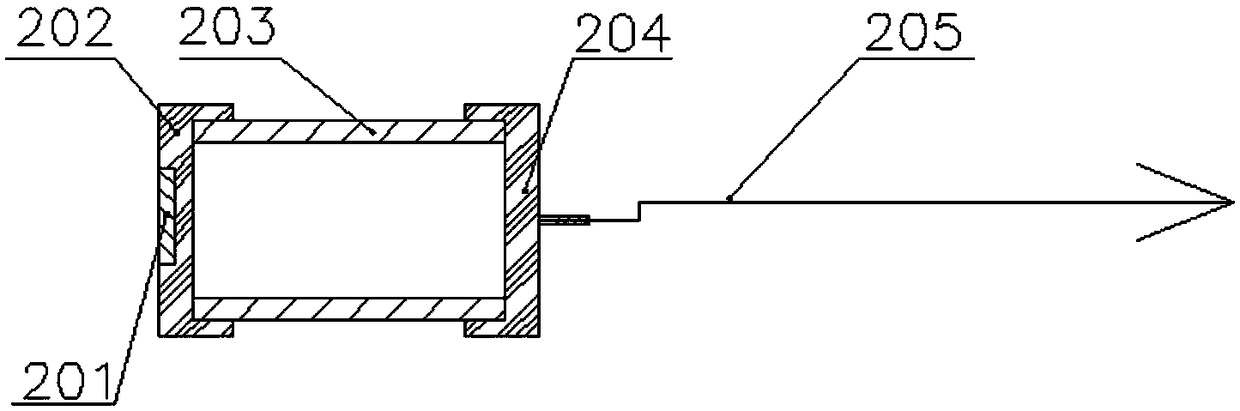

[0040] Such as figure 1As shown, the shaft center beating track testing device of the present invention includes a coaxially installed magnetic housing 1 , a magnetic suspension brush 2 , a coordinate card fixing piece 3 , a coordinate card 4 and a shaft end adsorption mechanism 5 . One end of the magnetic housing 1 is connected to one end of the shaft end adsorption mechanism 5, and the other end of the shaft end adsorption mechanism 5 is adsorbed to one end of the shaft 7 to be measured by magnetic force; one side of the coordinate card 4 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com