Coat hanger for garment machining

A technology of machinery and clothing, applied in the direction of hangers, clothing, applications, etc., can solve the problems of increased inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

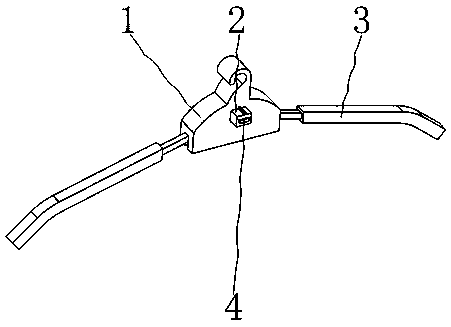

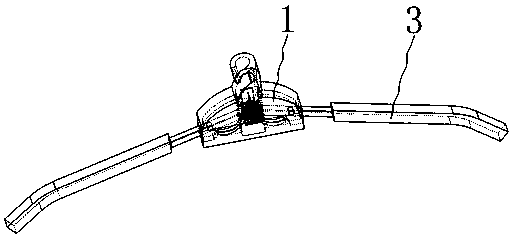

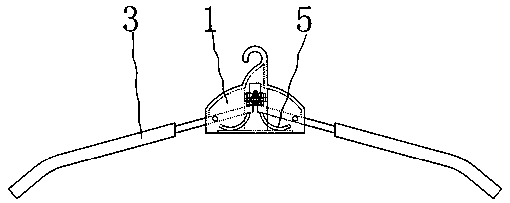

Image

Examples

specific Embodiment approach

[0048] The specific embodiment: when using the clothes hanger designed by the present invention, when people are hanging clothes, they will hang the clothes on the clothes hanger gently at first, but their hands will drag the clothes, and now the clothes support bar 3 will be given to it by the clothes. A pressure, the clothes support bar 3 will swing downward, and the swing of the clothes support bar 3 will squeeze the limit block 7, so that the limit block 7 slides along the second guide groove 26, and the slide of the limit block 7 will drive the first One rack 19 moves, and the first rack 19 moves and will drive the second gear 31 that meshes with it to rotate, and the second gear 31 rotates to drive the rotation shaft 32 to rotate, and the rotation of the rotation shaft 32 drives the first gear 29 to rotate, and the first gear 29 The rotation will drive the second rack 20 to move, and the movement of the second rack 20 will drive the marking plate 30 installed on it to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com