Miniature combing device used for artificial fur machine and provided with multi-speed working roll

A technology of work rolls and fur machines, applied in deburring devices, fiber processing, textiles and papermaking, etc., can solve the problem of uneven distribution of discrete fibers, and achieve the effect of uniform fiber distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples.

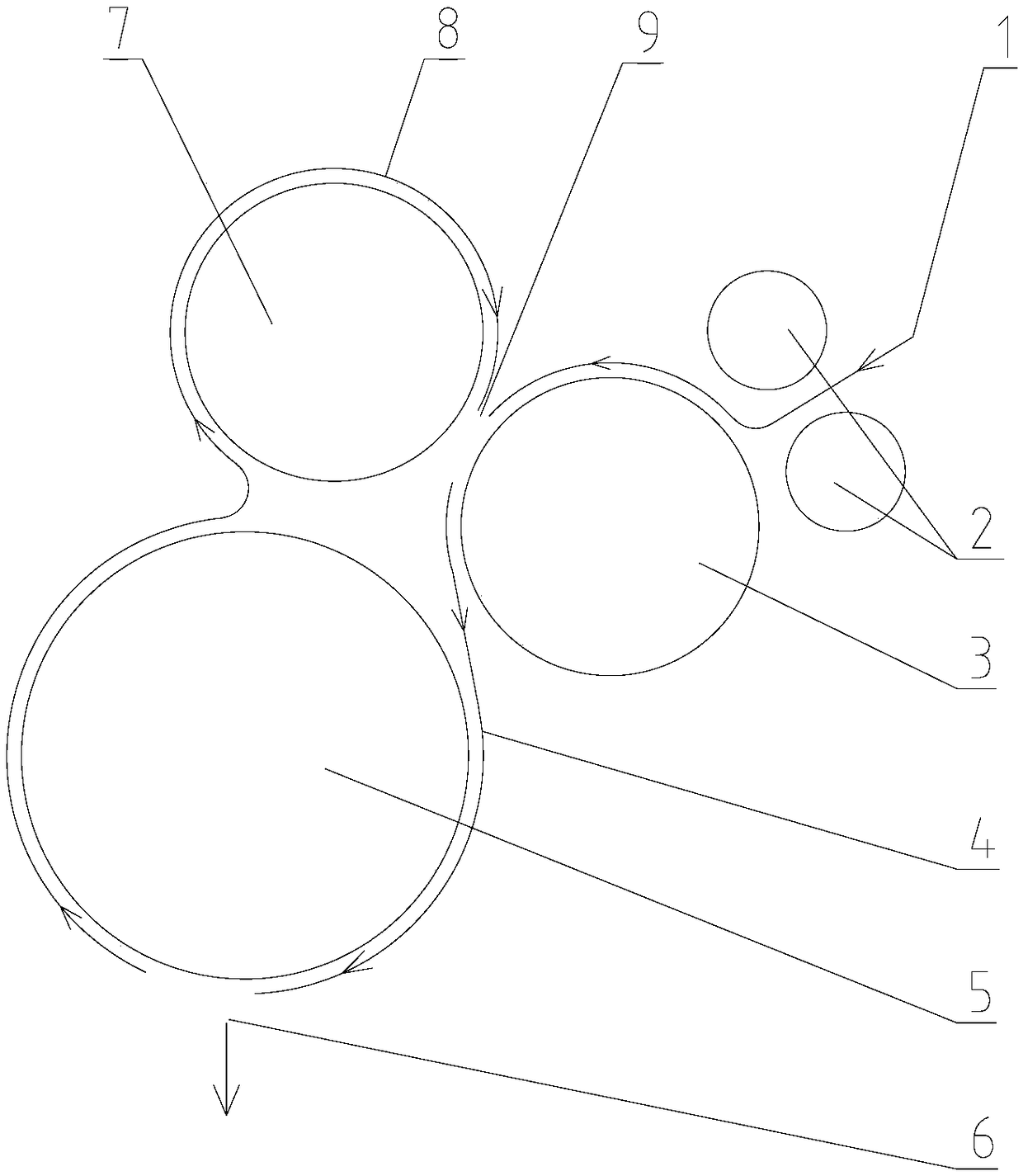

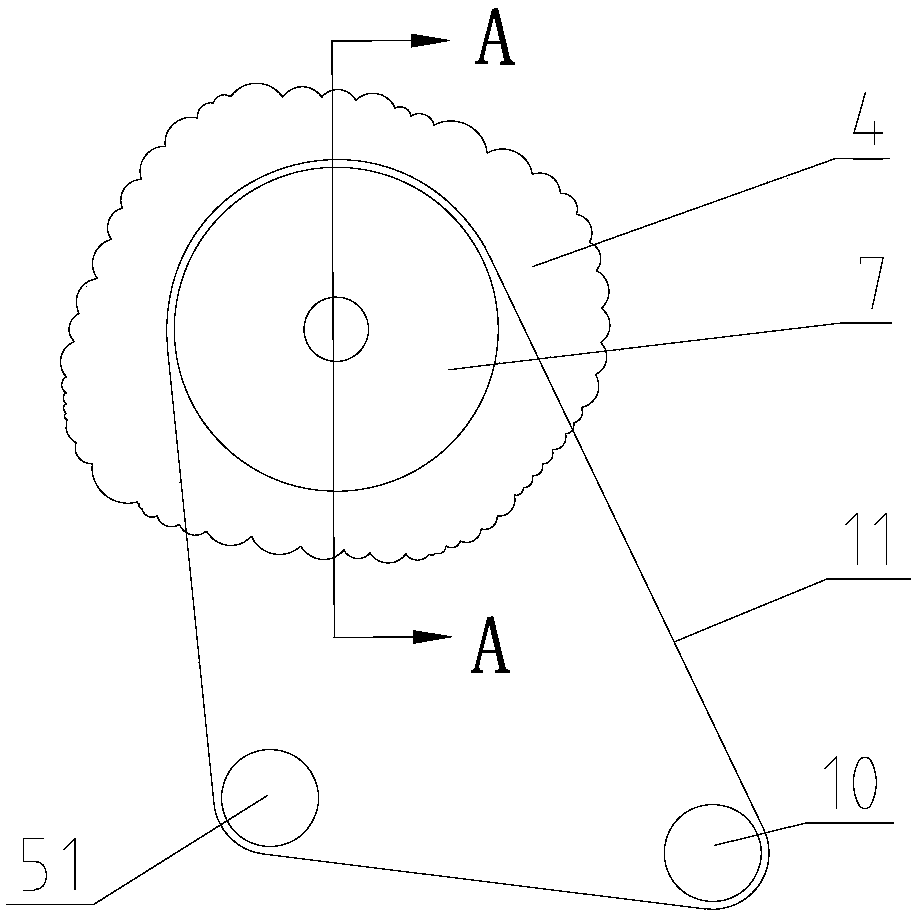

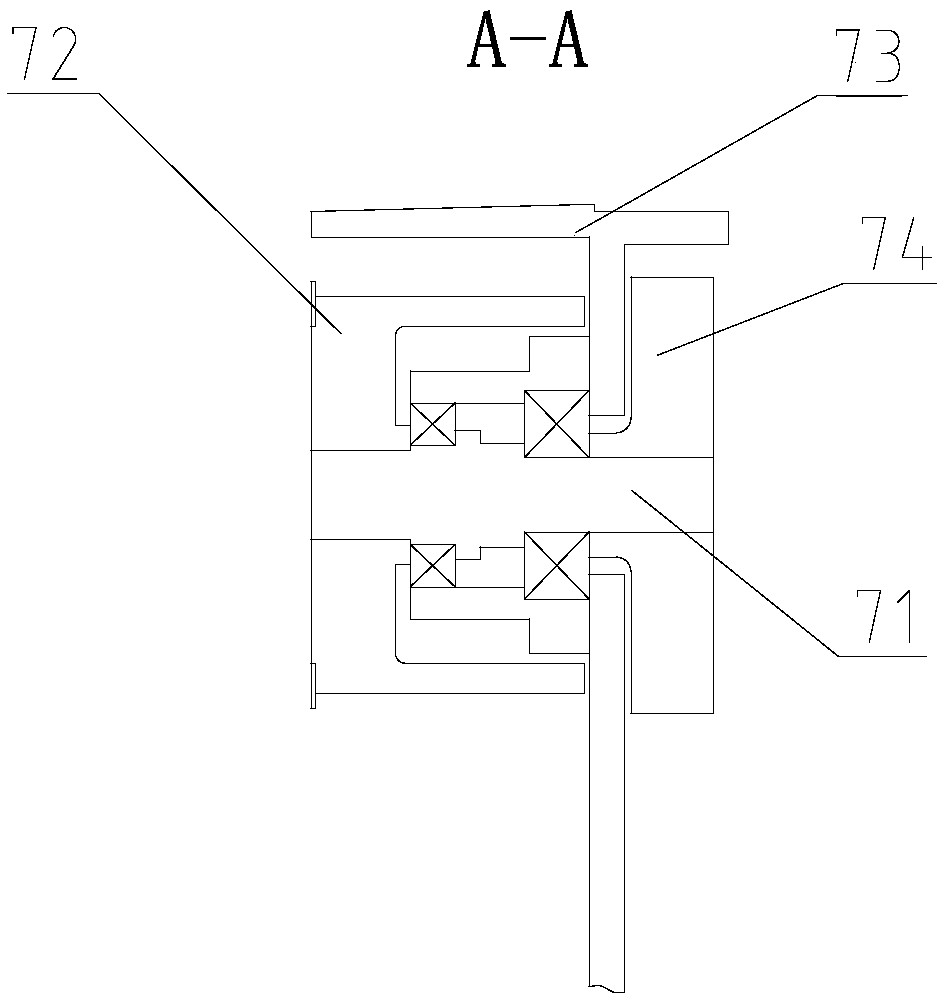

[0018] Such as Figure 4-Figure 5 As shown, the artificial fur machine multi-speed working roller micro-carding device is provided with a feed roller 2, a cylinder 3, a doffer 5 and a new working roller assembly 700, and the new working roller assembly is provided with a housing 701 and an input assembly 710 , an intermediate component 720 and a working component 730 . The input assembly 710 is provided with an input fixed shaft 711, and the input fixed shaft 711 is fixedly provided with an input pulley 713 and an input gear 712; Speed gear 723, the first low-speed gear 724 and intermediate gear 725; Working assembly 730 is provided with high-speed shaft 731, and the detachable fixing on high-speed shaft 731 is provided with high-speed roller segment 739 and second high-speed gear 734, and high-speed shaft 731 passes bearing simultaneously It is connected with the medium-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com