Complete equipment of turbine

A complete set of equipment, steam turbine technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of inconvenient replacement of impeller sets for work efficiency, increased maintenance costs, and damage to turning motors, so as to improve work efficiency and structure Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

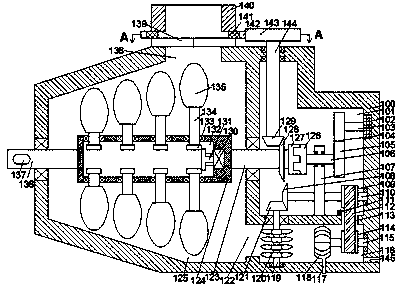

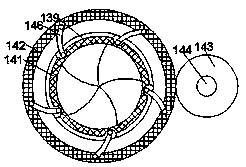

[0013] like Figure 1-Figure 2 As shown, a steam turbine complete set of equipment of the present invention includes a fuselage 100 and a first cavity 101 arranged in the fuselage 100, and a A steam outlet chamber 116, a transmission channel 113 is provided between the first cavity 101 and the steam outlet chamber 116, and a working chamber 125 located at the left end of the first cavity 101 is provided in the fuselage 100, The working chamber 125 communicates with the steam outlet chamber 116 and is provided with an exhaust passage 122. The inner wall of the left end of the first cavity is rotatably connected with a first transmission shaft 123 extending left and right. The first transmission shaft 123 The left end is fixedly connected with the impeller box 124 located in the working chamber 125, the first transmission shaft 123 is provided with a first bevel gear 128 located in the first cavity 101, and the first transmission shaft 123 There is a first meshing plate 127 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com