Method for determining thickness of edge wall treatment layer in coarse-grained soil permeation test

A determination method, a technology of coarse-grained soil, applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., can solve the problem of large test data, dirty sample normal pores, small test data, etc. problems, to achieve the effect of avoiding small test results, eliminating side wall effects, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

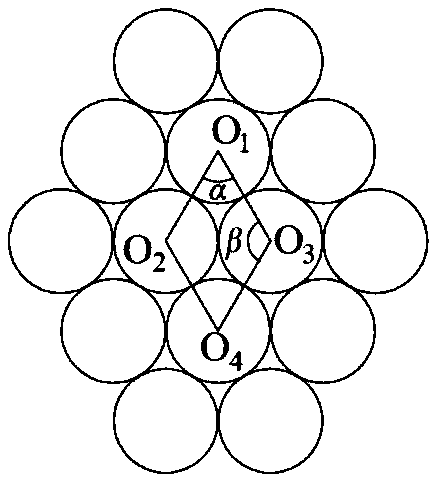

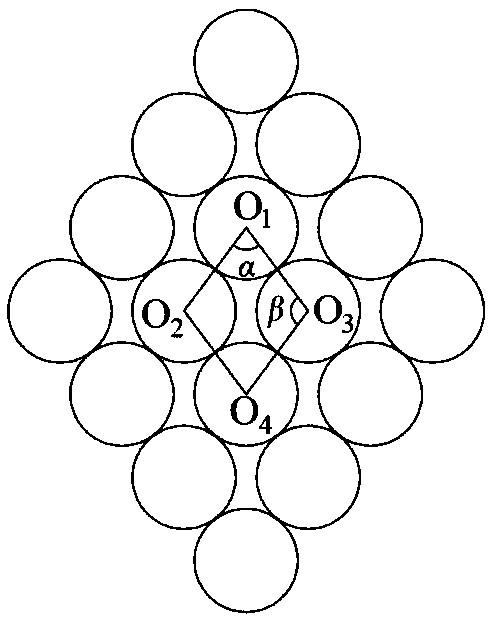

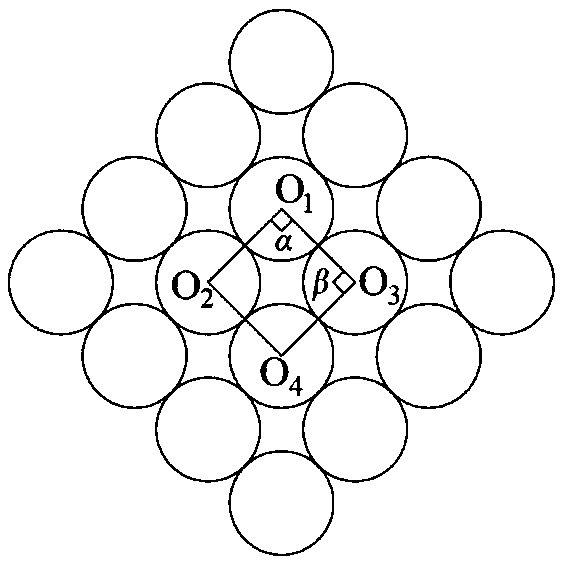

[0049] A method for determining the thickness of a side wall treatment layer in a coarse-grained soil permeability test, the steps of which are as follows:

[0050] (1) Particle size composition of coarse-grained soil

[0051] From the particle sieving test, the percentage M of the particle mass of the jth particle size group of the coarse-grained soil used for the coarse-grained soil penetration test in the total mass of the dry soil is obtained j , j=1,2,3...J, j is the sequence number of the sieved particle size group, and J is the number of sieved particle size groups;

[0052] Calculate the median particle size d of the jth particle size group j :

[0053]

[0054] In the formula, d j,max is the upper limit particle size of the jth particle size group; d j,min is the lower limit particle size of the jth particle size group;

[0055](2) Determination of the particle density of each particle size group

[0056] Measure the particle density ρ of the jth particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com