A high and medium pressure chromatographic column with shrinkage and smooth connection at both ends

A smooth connection and chromatographic column technology, which is applied in the field of chromatographic columns, can solve the problems of difficult distribution of inlet samples and achieve the effects of increasing effective separation length, good separation effect, and reducing diffusion and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

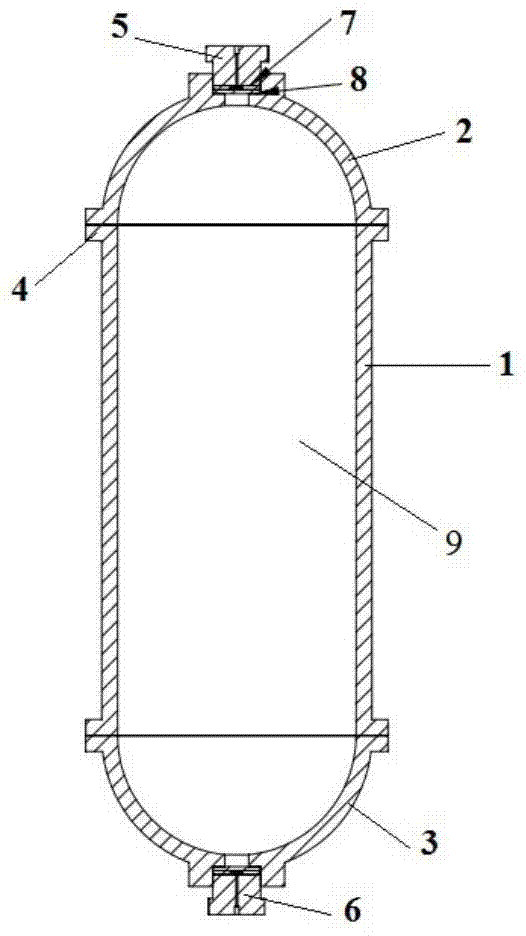

[0033] A high- and medium-pressure chromatographic column with shrinkage and smooth connection at both ends, which adopts the design of a smooth connection with both ends shrinkage. The smooth connection can avoid the mixing back of fluid at the interface and affect the separation.

[0034] The chromatographic column is composed of a main separation column tube 1, a column head 2 and a column tail 3 with an arc-shaped concave inside. A mobile phase inlet 5 and an outlet 6 are provided; a distribution plate 7 and a sieve plate 8 are used to seal the packed stationary phase 9 .

[0035] The column tube 1, the column head 2 and the column tail 3 can be integrated, or processed separately and connected by a flange seal. The column tube, column head and column tail can be made of stainless steel, glass or polymer;

[0036] The interior of the column head and column tail is arc-shaped concave from the opening connected with the column tube to the top opening, which can be spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com