Device and method for detecting anti-seepage performance of granular material

A technology for particulate materials and detection devices, which can be used in measurement devices, analytical materials, suspension and porous material analysis, etc., and can solve problems such as eliminating the influence of side wall effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

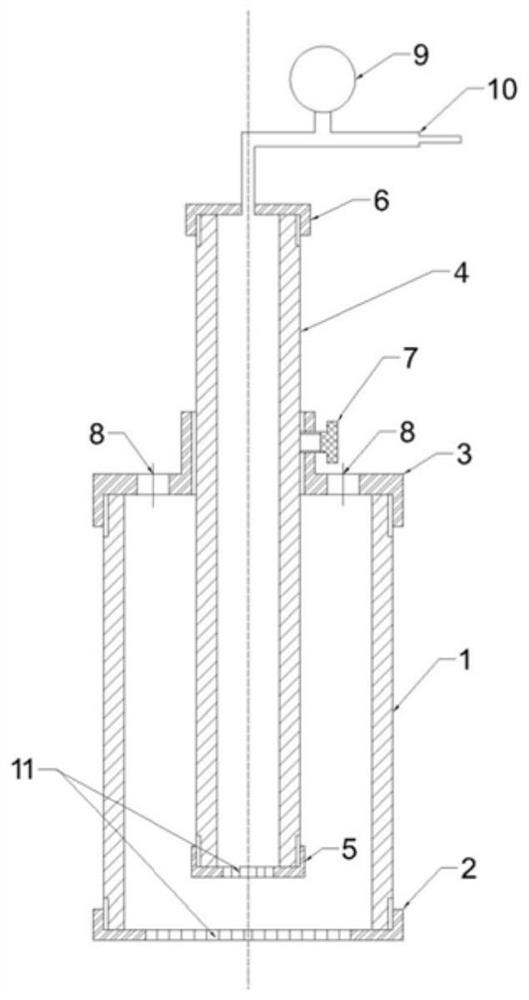

[0035] A detection device for the anti-seepage performance of granular materials, such as figure 1 As shown, it includes an outer cylinder 1 and an inner cylinder 4 inserted in the outer cylinder 1. The bottom of the inner cylinder 4 is located inside the outer cylinder 1 and is spaced apart from the bottom of the outer cylinder 1. Between the outer cylinder 1 and the inner cylinder 4 The space in the space is used to constrain the natural accumulation of granular materials to be measured in the space into a cylindrical container shape. The top of the inner cylinder 4 protrudes from the top of the outer cylinder 1 and is used for water intake. The bottoms of the inner cylinder 4 and the outer cylinder 1 are both Water permeable holes 11 are provided.

[0036] In this embodiment, preferably, the top of the inner cylinder 4 is provided with an inner cylinder top cover 6, and is connected with a water inlet pipe, and a pressure gauge 9 and a water inlet valve 10 are arranged on t...

Embodiment 2

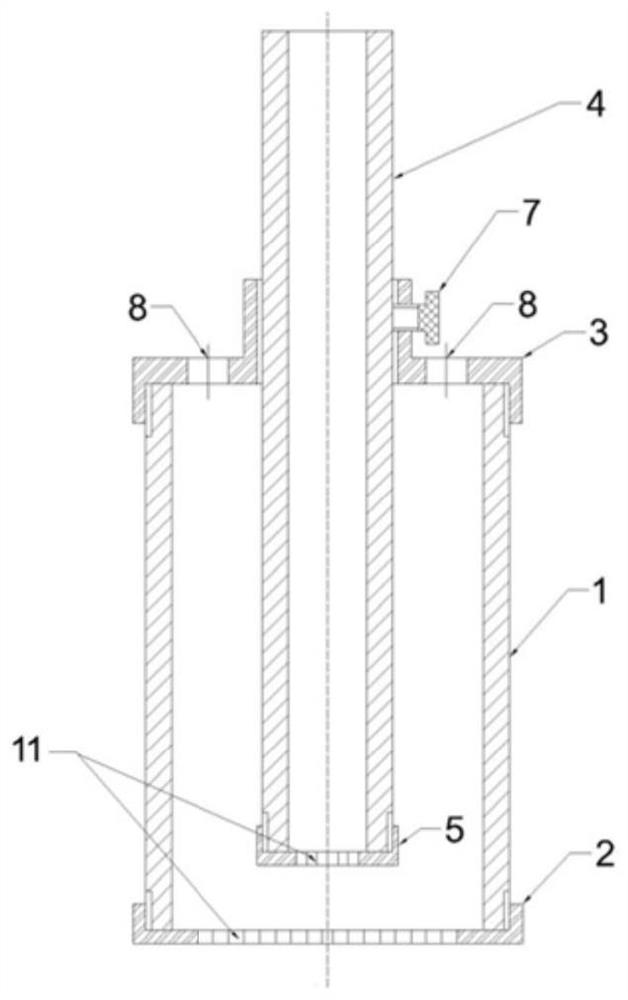

[0059] A detection device for the anti-seepage performance of granular materials, such as figure 2 As shown, it includes an outer cylinder 1 and an inner cylinder 4 inserted in the outer cylinder 1. The bottom of the inner cylinder 4 is located inside the outer cylinder 1 and is spaced apart from the bottom of the outer cylinder 1. Between the outer cylinder 1 and the inner cylinder 4 The space in the space is used to constrain the natural accumulation of granular materials to be measured in the space into a cylindrical container shape. The top of the inner cylinder 4 protrudes from the top of the outer cylinder 1 and is used for water intake. The bottoms of the inner cylinder 4 and the outer cylinder 1 are both Water permeable holes 11 are provided.

[0060] In this embodiment, the top of the inner cylinder 4 is preferably open.

[0061] The detection method of the anti-seepage performance of the granular material adopts the detection device of this embodiment, and the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com