Vacuum chuck

A vacuum suction cup, suction cup technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of decreased bonding accuracy and increased wafer spacing, and achieve the effect of improving wafer bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

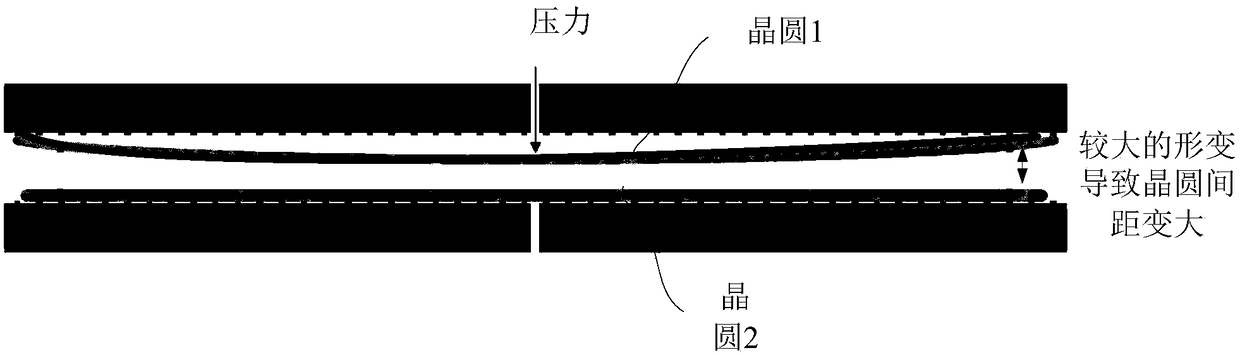

[0033] In the industry, in order to compensate for the size difference between the two wafers to be bonded due to the wafer size change during the wafer processing process, thereby improving the alignment accuracy of wafer bonding, different pressures are usually applied to the wafer through vacuum chucks , however, as figure 1 As shown, the pressure applied to the wafer is not applied uniformly over the entire area of the wafer, but is applied to a local area of the wafer, for example, through a force application point, which is usually located near the center of the wafer, and Each wafer has a certain area, so that different regions of the wafer have the problem of uneven force. Therefore, under the pressure, the wafer will deform in the direction perpendicular to the surface of the wafer, so that the bonded The distance between the two wafers in the wafer edge area increases, which leads to an inevitable decline in bonding accuracy.

[0034] In order to solve the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com