Leakproof connection buckle of mining conveying belt

A technology for connecting buckles and conveyor belts. It is applied to belt fasteners, belts/chains/gears, mechanical equipment, etc., and can solve problems such as affecting service life and effect, leakage of debris such as coal ash, and easy damage to conveyor belts. , to prevent leakage, ensure cleanliness, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

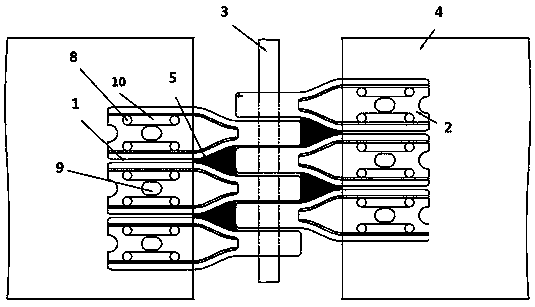

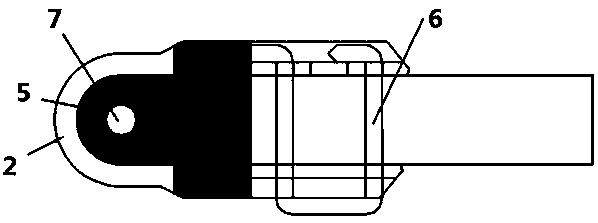

[0014] In the figure: including connecting buckle assembly 1, connecting buckle 2, fixing cable 3, belt 4, rubber plastic part 5, saddle nail 6, rubber inner hole 7, nail hole 8, buffer hole 9, bending guide groove 10, all The connecting buckle assembly 1 described above is formed by connecting a plurality of connecting buckles 2 side by side. Four nail holes 8 are arranged in a rectangle on the upper side wall and the lower side wall of the connecting buckle 2, and the connecting buckle 2 passes through the nail holes through the saddle nail 6. 8. Fix the belt 4. There is a rubber plastic part 5 between the connecting buckles 2 connecting the two ends of the belt 4. A rubber inner hole 7 is provided in the middle of the rubber plastic part 5. The connecting buckles 2 at both ends pass through the fixing rope 3. The rubber inner hole 7 fixes the belts 4 on both sides, and a buffer hole 9 is provided between the four nail holes 8 to form a leak-proof connection buckle for a mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com