Heating and cooling system for automobile power battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

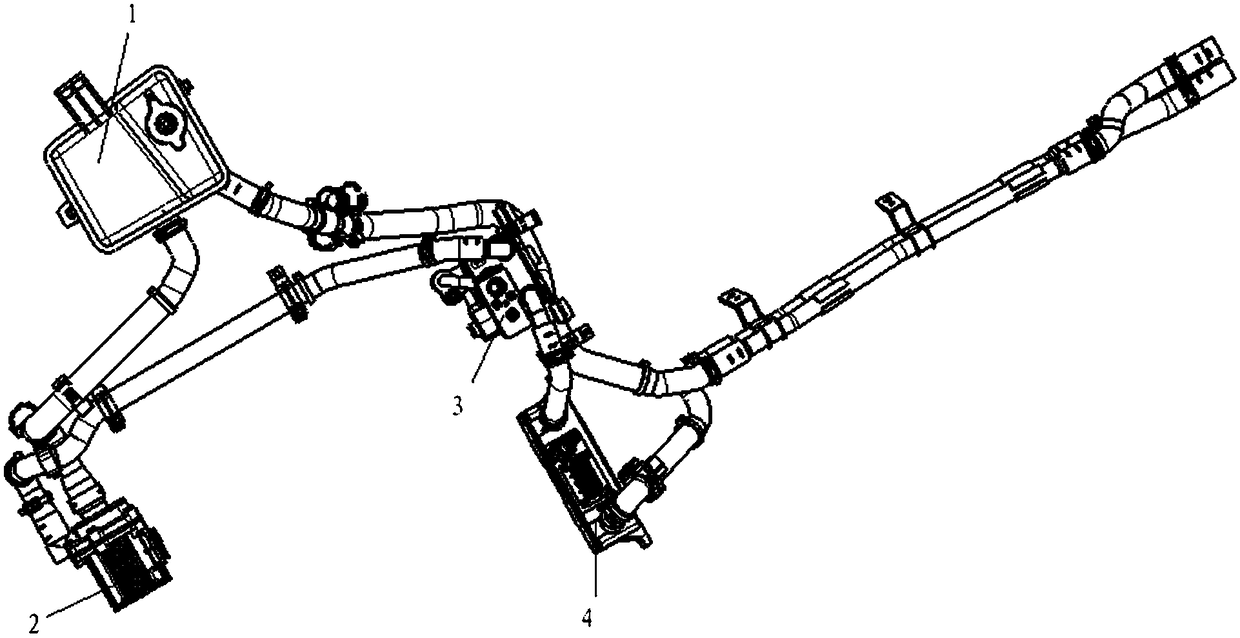

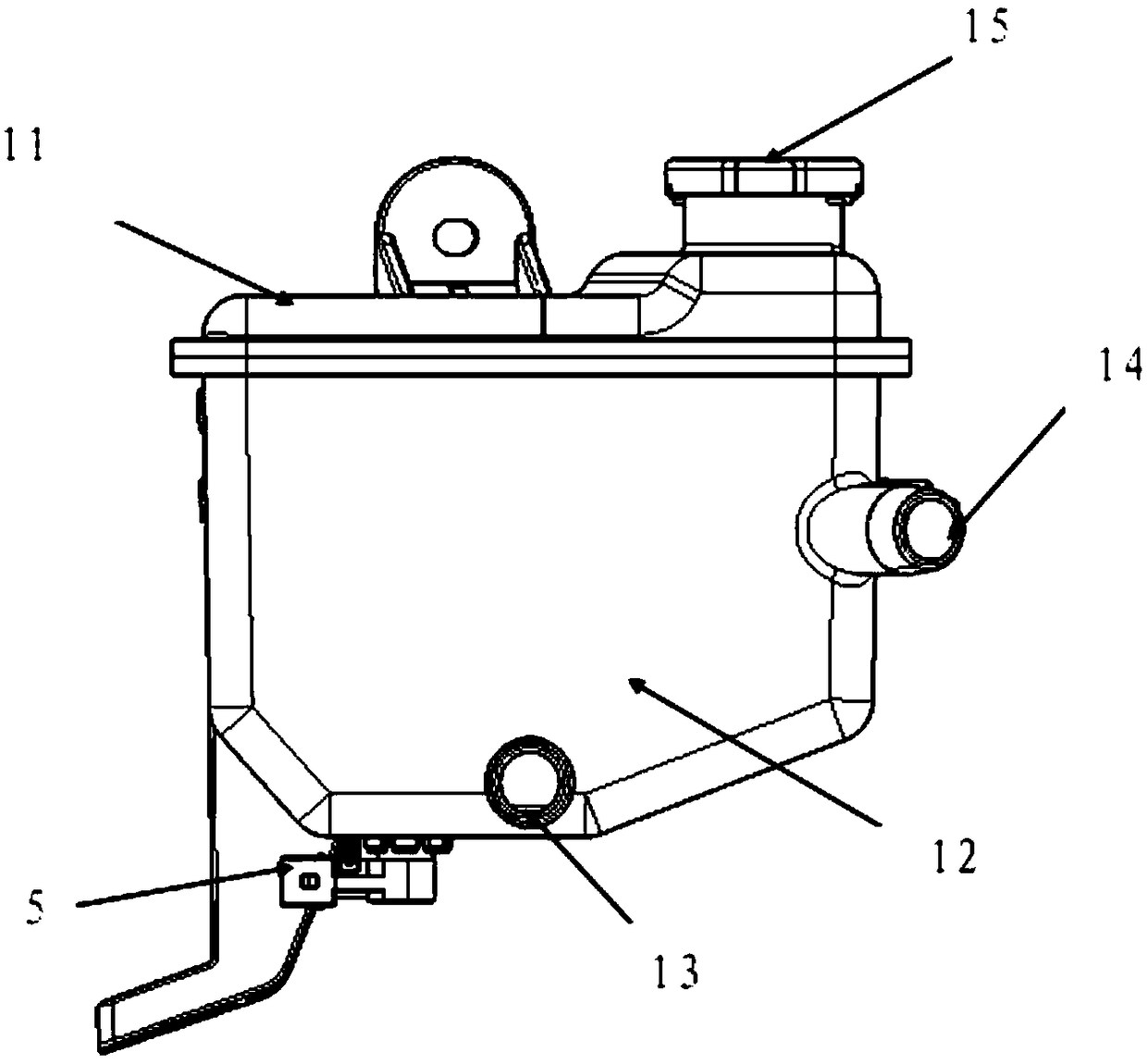

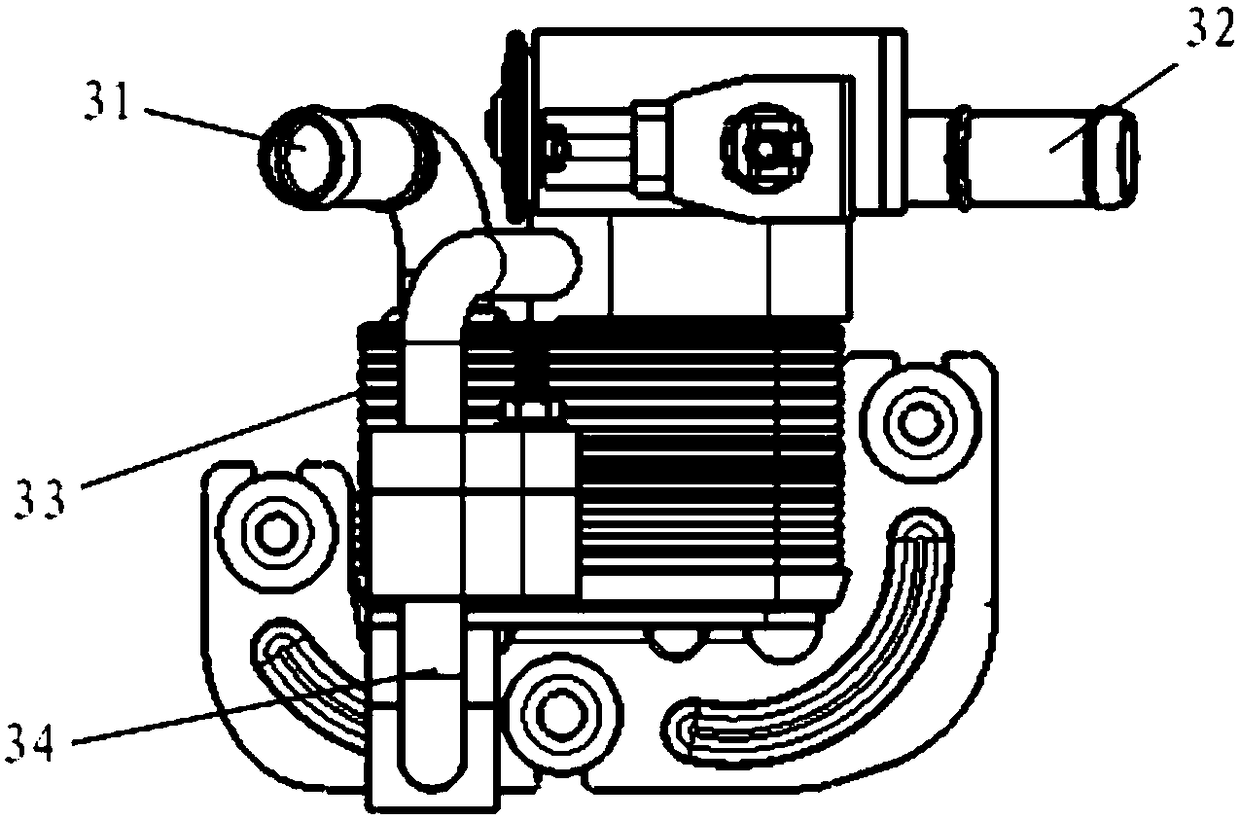

[0053] For the thermal management of the power battery of the current electric vehicle, an independent heating system and a cooling system are used, and the preparation cost is high. The invention provides a heating and cooling system for an automobile power battery. The battery cooler and the heater are connected in series through pipelines, and an expansion kettle and a circulating water pump are arranged on the pipeline so that the cooling liquid flows through the battery cooler and the heater. Furthermore, the cooling or heating of the power battery can be realized, and the problem of high production cost and low efficiency caused by the independent system for heating and cooling of the power battery of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com