Precipitation reactor for producing organic substance treatment catalyst

A technology for catalysts and organic matter, applied in the field of precipitation reactors for the production of organic matter treatment catalysts, can solve problems affecting catalyst performance and homogeneity, increase maintenance costs, reduce product quality, etc., and achieve simple structure, high safety, and heating effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

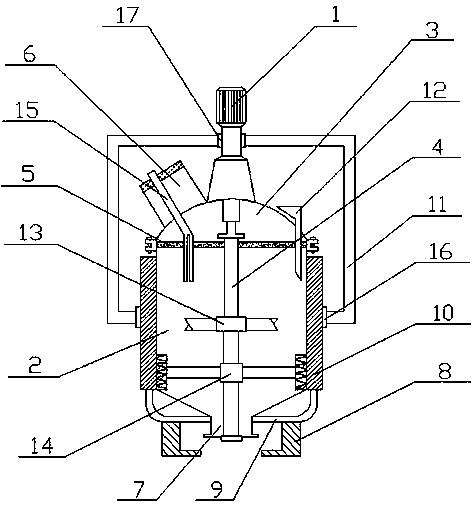

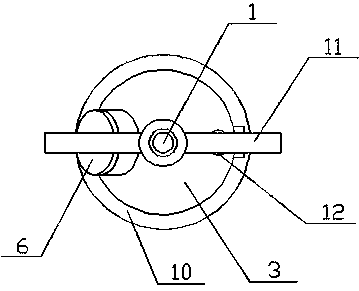

[0019] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0020] As shown in the figure, a precipitation reactor for producing organic matter treatment catalyst includes a motor 1, a tank body 2, a top cover 3, a transfer shaft 4, a bracket 9 and a base 8, and the motor 1 is installed on the transfer shaft 4 extending out of the top On the upper end of the cover 3, the top cover 3 is provided with an inlet 6 and a liquid inlet pipe 12, the transfer shaft 4 is vertically arranged, and the transfer shaft 4 is located in the part of the tank body 2, and a horizontally arranged agitator 13 is installed in the middle , the lower end of the intermediate shaft 4 is provided with the discharge port 7 of the tank body 2, the bracket 9 is placed at the bottom of the tank body 2 and fixed on the base 8, and the tank body 2 is also provided with a descaling device 14 , the descaling device 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com