Automatic grouting forming device for ceramic blanks

A technology for automatic grouting and ceramic body, which is applied in the direction of ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of uneven thickness of the body, low production efficiency, and inability to standardize production, and achieve low production costs, The effect of high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

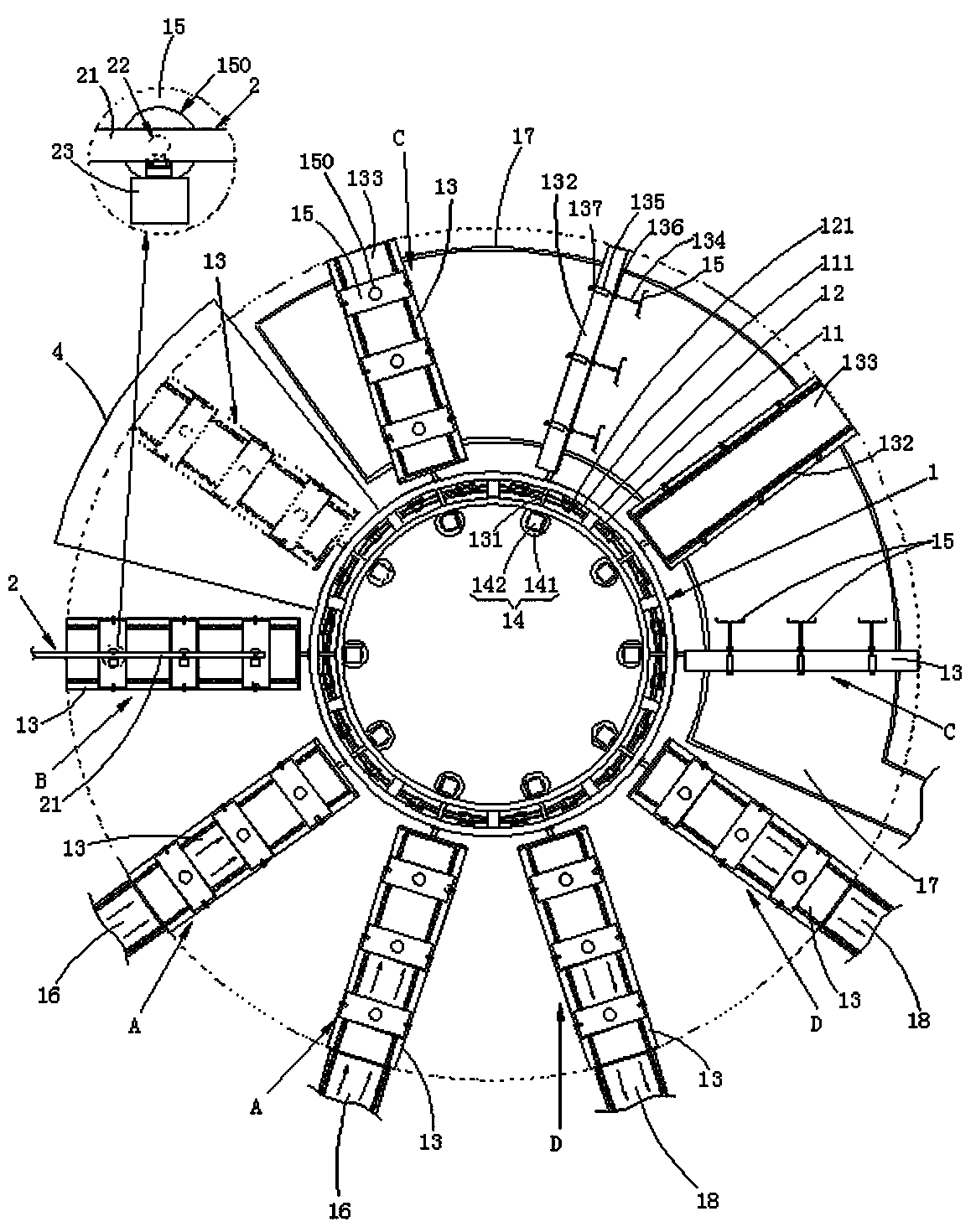

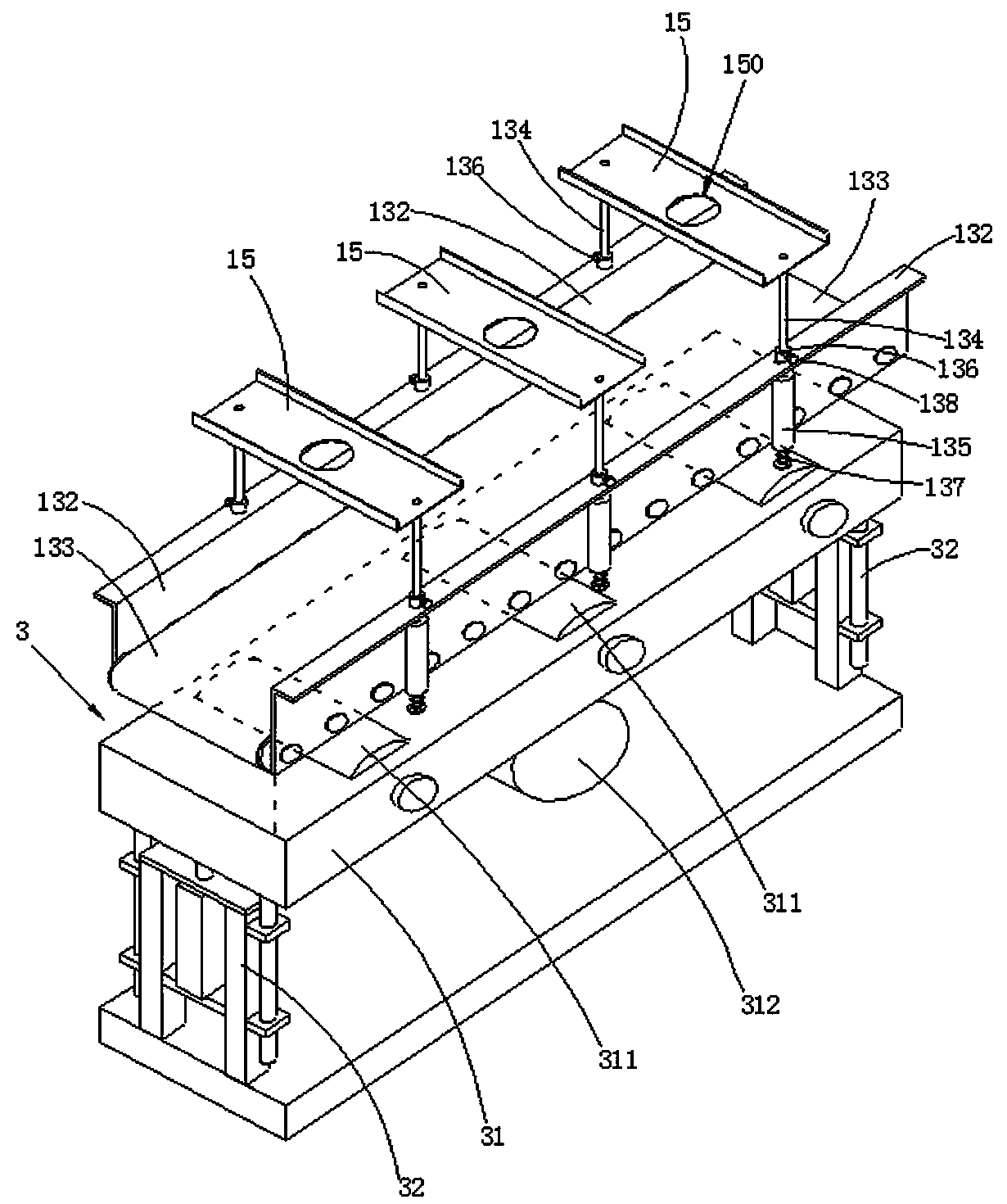

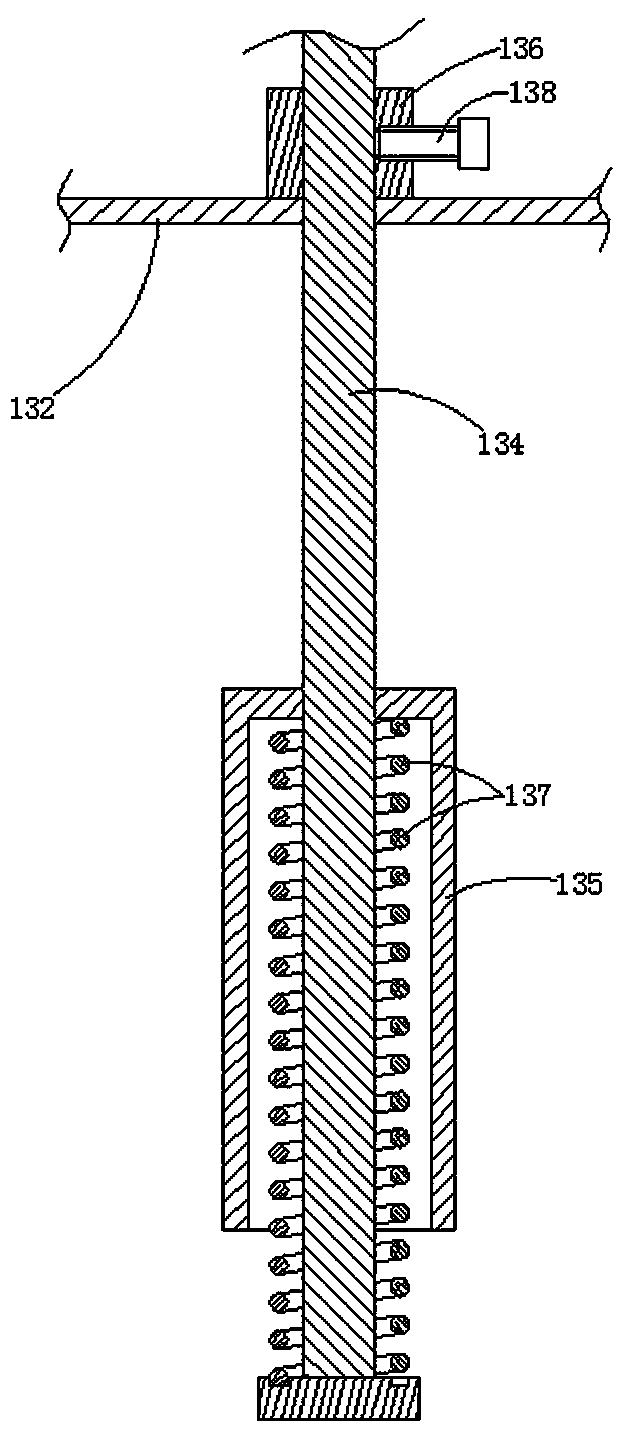

[0025] refer to figure 1 , figure 2 , image 3 , This embodiment relates to an automatic grouting molding device for a ceramic body, including a main frame 1 and an upper mold station A, a grouting station B, a pouring station C and a mold ejection station arranged on the main frame 1 D; the above-mentioned main frame 1 includes a base 11 and a rotating frame 12, and the rotating frame 12 is assembled on the base 11 for fixed-axis rotation; the top surface of the above-mentioned base 11 is provided with a circular guide rail 111, and the above-mentioned rotating The bottom of the frame 12 is equipped with several pulleys 121, and the pulleys 121 slide directionally along the guide rail 111, and the base 11 is equipped with a hydraulic motor that drives the rotating frame 12 to rotate. The peripheral surface of the rotating frame 12 is provided with ten mold-carrying tables 13 for placing moulds. The mold-carrying tables 13 are mounted on the rotating frame 12 through a driv...

Embodiment approach 2

[0031] The difference between the automatic grouting molding device for ceramic body in this embodiment and the automatic grouting molding device in Embodiment 1 is that: refer to Figure 4 , Figure 5 , the driving mechanism 14 adopted in this embodiment is a simple way with low cost. The driving mechanism 14 of this embodiment includes a driving wheel 143, a limit wheel 144 and a guide rail 145, and the driving wheel 143 is fixedly assembled on the above-mentioned driving shaft 131 , the limit wheel 144 is coaxially assembled on the eccentric position of the drive wheel 143, and the guide rail 145 is fixedly assembled on the above-mentioned main frame 1, and the guide rail 145 is preferably two upper and lower parallel arrangements. The limit wheel 144 Then it is assembled between two guide rails 145, and the limit wheel 144 slides along with the extension of the guide rails 145; the guide rail 145 of the pouring station C has at least one peak section 146 and at least one w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com