Stirring device for building construction

A mixing device and building construction technology, which is applied in the direction of cement mixing device, unloading device, clay preparation device, etc., can solve the problems of high cost, internal worker injury, inconvenient observation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

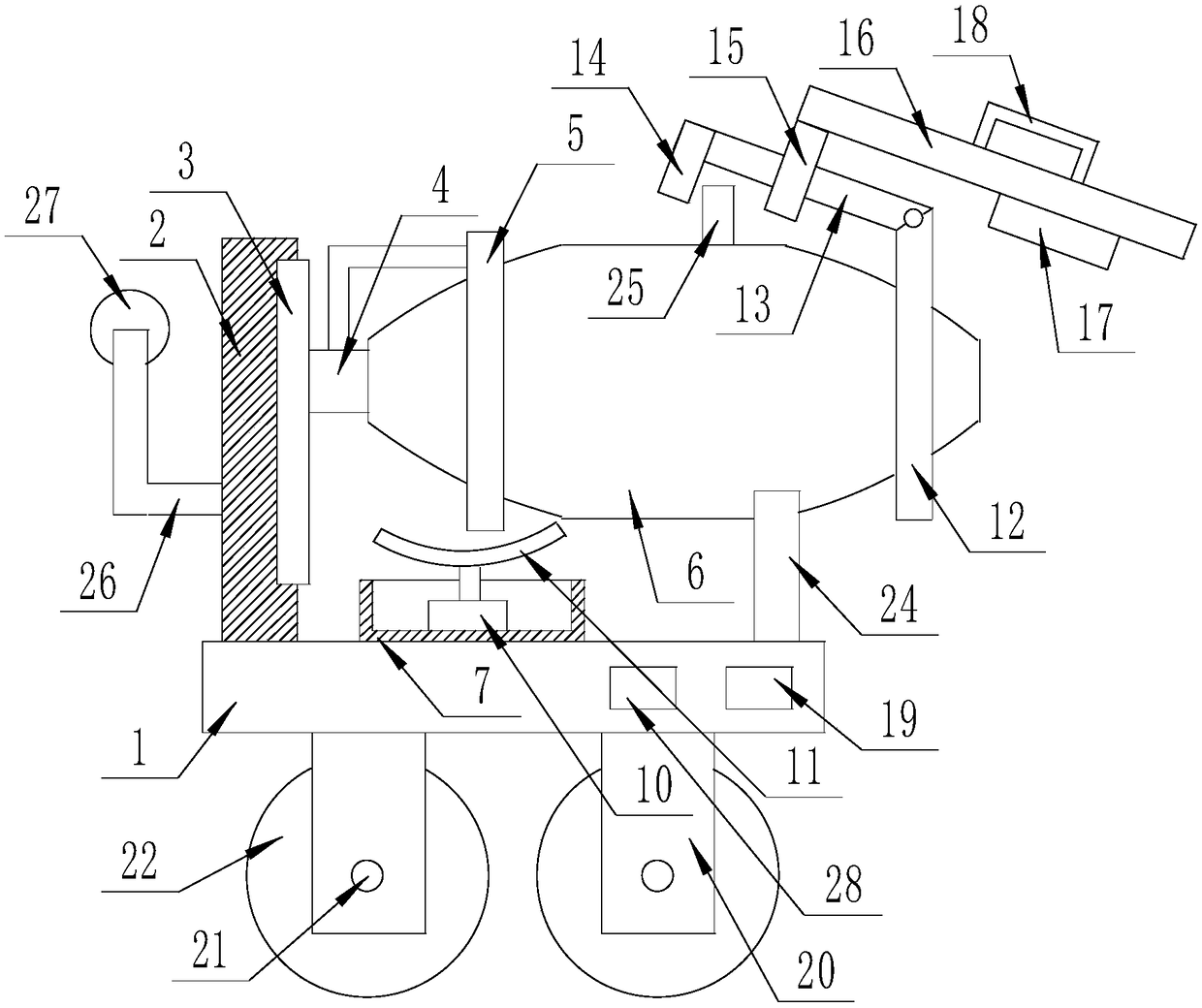

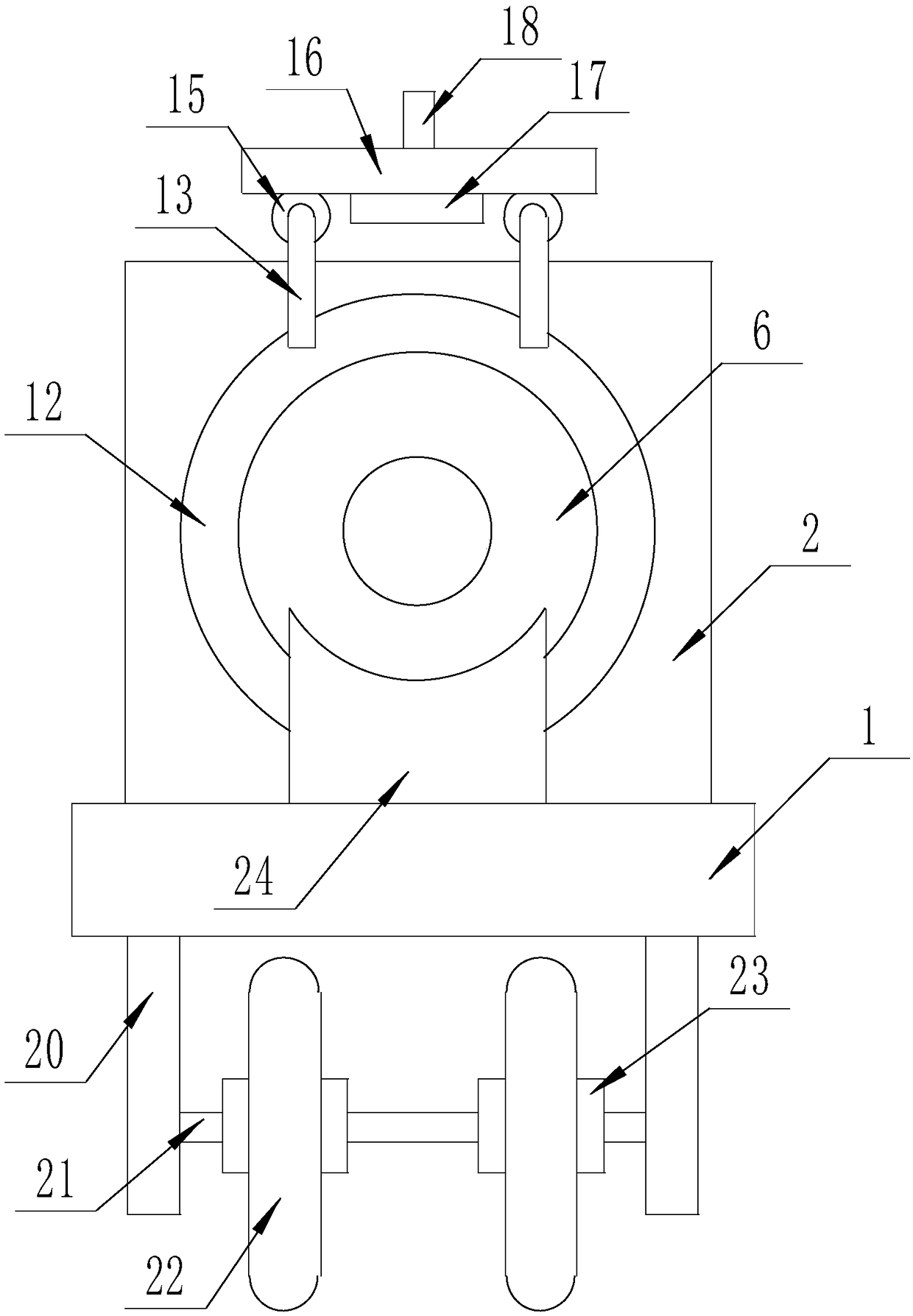

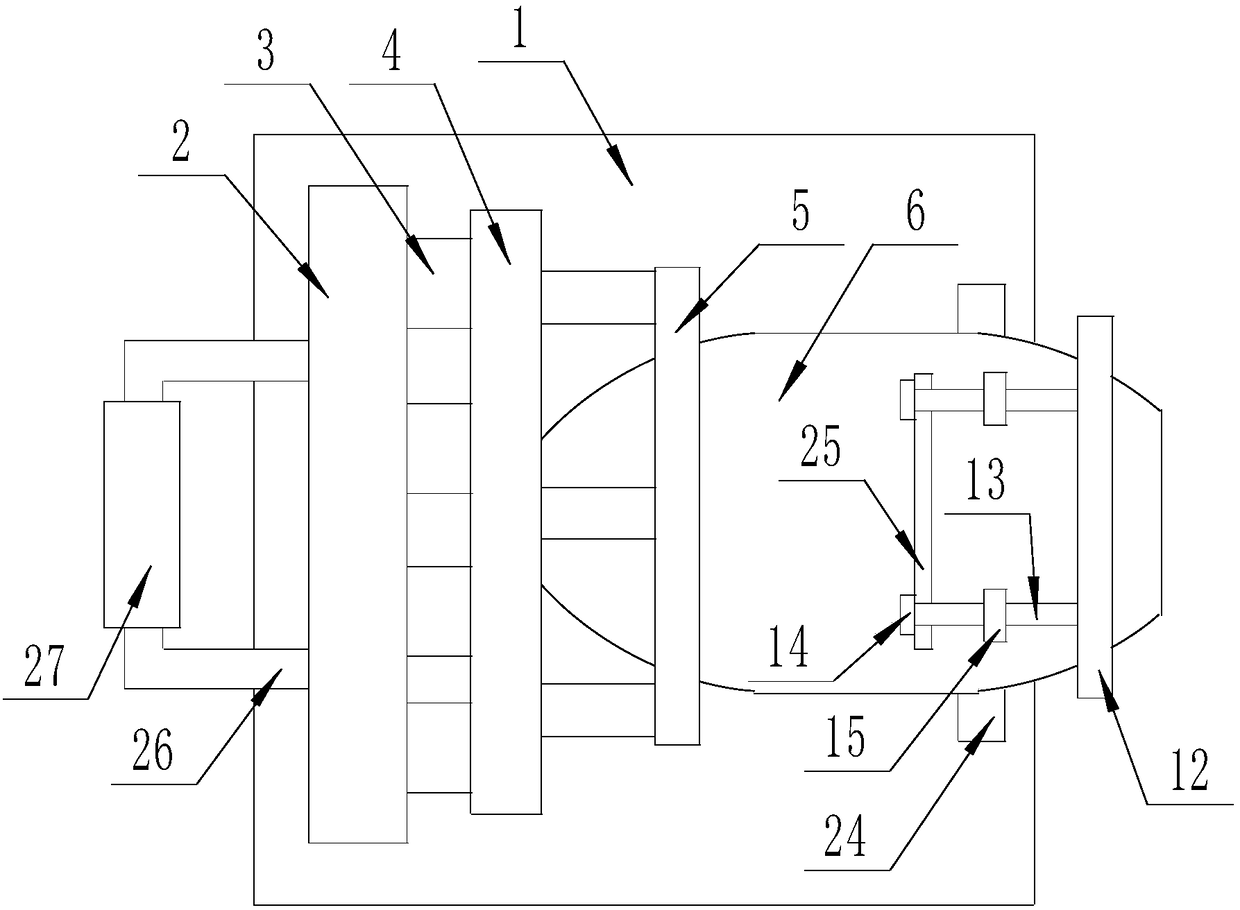

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a stirring device for building construction includes a strip-shaped bearing base 1, the upper surface of the strip-shaped bearing base 1 is provided with a stirring mechanism with a protective function, and the lower surface of the strip-shaped bearing base 1 is A moving mechanism is provided, and the stirring mechanism with protection function is mainly composed of a strip support frame 2 arranged on one end of the upper surface of the strip support base 1, several vertical slides embedded on the inner surface of the strip support frame 2 Road 3, the elevating sliding frame 4 that is arranged on the inner side of the strip support frame 2 and connected with several vertical slides 3, several swinging fixed frames 5 that are hinged on the side surfaces of the elevating sliding frame 4, are arranged on several The mixing drum 6 on the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com