Glass fiber reinforced plastic air duct for rail vehicle

A rail vehicle and FRP technology, applied in the field of rail transit, can solve the problems of aging replacement, high maintenance cost of occupied space, unfavorable aluminum alloy forming special-shaped parts, poor sound insulation and heat insulation effect, etc., to save installation space and maintain flatness , the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

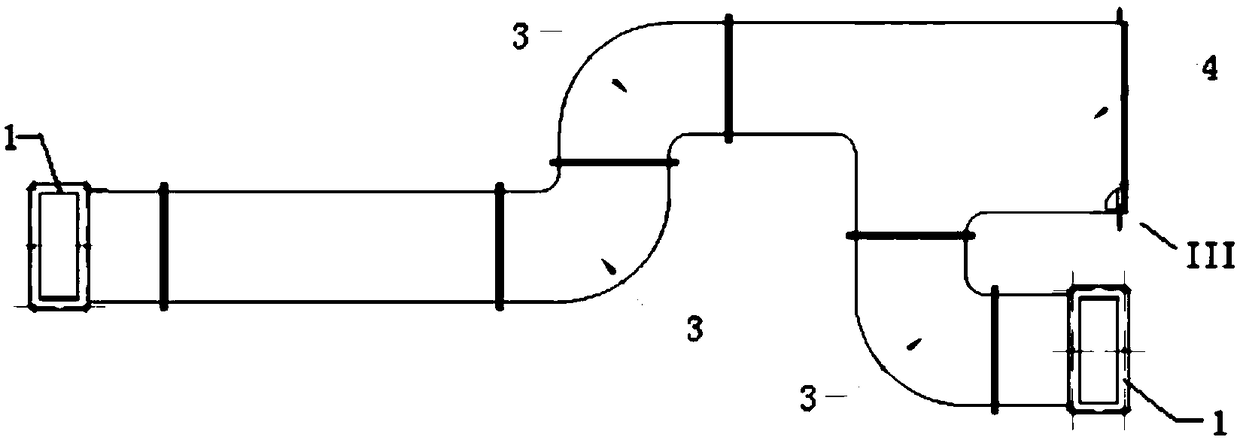

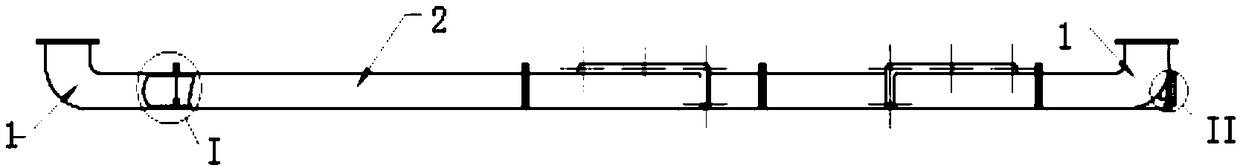

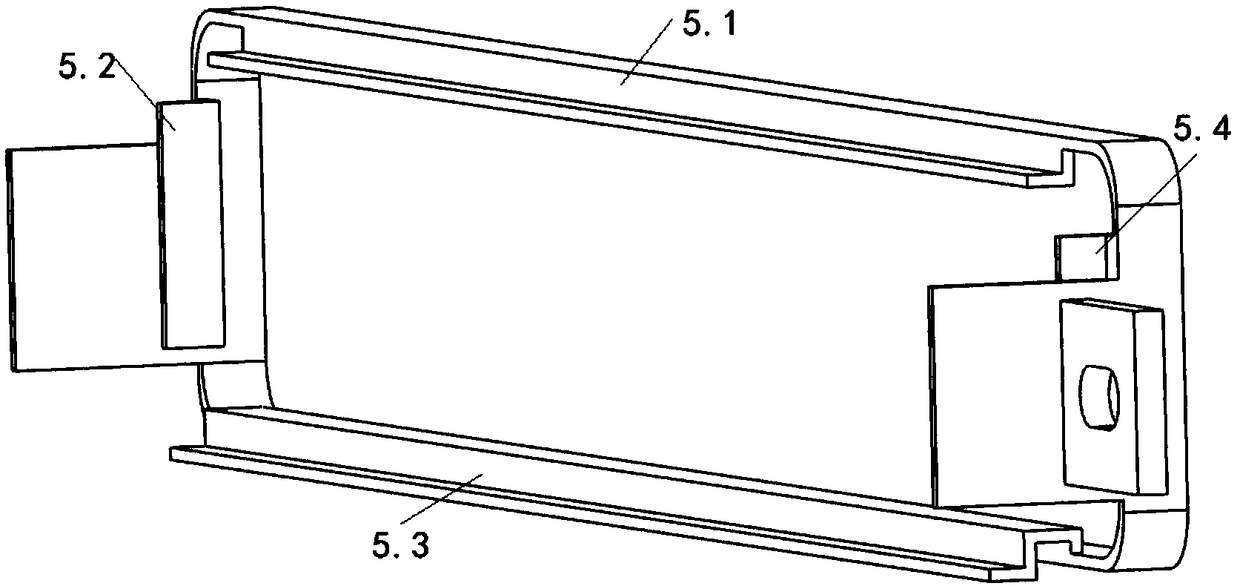

[0030] see Figure 1 to Figure 8 , a fiberglass air duct for rail vehicles, including a plurality of sub-air ducts, the sub-air ducts include an air inlet duct 4, a horizontal air duct 2, a curved air duct 3, and an air outlet duct 1. The air duct 4 is connected to the air outlet duct 1 through the curved air duct 3 and the horizontal air duct 2, and each sub-air duct is connected by a flange, and the inner side of the flange is provided with a sealing member 8, and each air duct connection method The flange is provided with a through hole, and the bolts pass through each air duct to connect the flanges and seals 8 and then tighten them, so that the air duct is connected as a whole. The flange has an asymmetric structure, and the flanges of the asymmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com